The Role of FR4 Epoxy Fiberglass Laminate Sheets in High-Frequency Circuit Design

2025-04-17 17:06:19

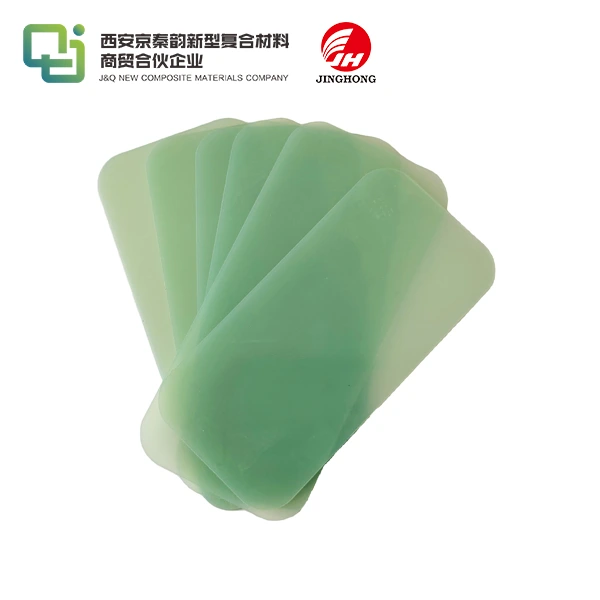

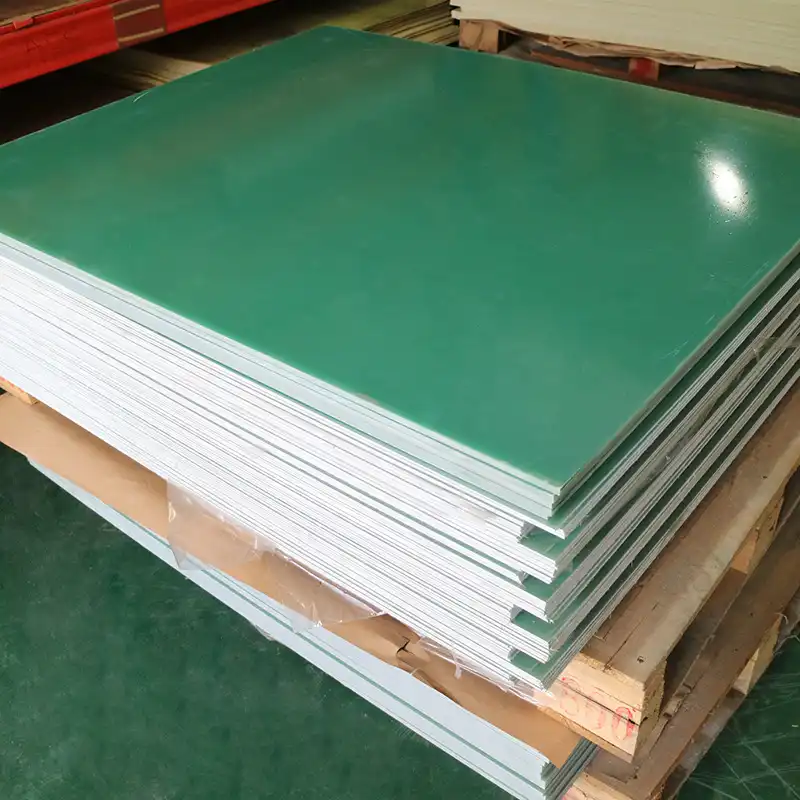

When it comes to high-frequency circuit design, the choice of materials can make or break performance. FR4 epoxy fiberglass laminate sheets play a pivotal role in this domain, offering a blend of electrical insulation, mechanical strength, and thermal stability. These sheets, crafted from woven fiberglass cloth impregnated with epoxy resin, provide a reliable substrate for printed circuit boards (PCBs) in high-frequency applications. Their low dielectric constant and loss tangent ensure minimal signal distortion, while their robust structure withstands the rigors of complex circuit layouts. Whether in telecommunications, aerospace, or consumer electronics, FR4 sheets are the backbone of efficient, high-speed circuitry, enabling designers to achieve precision and durability in demanding environments.

Understanding the Core Properties of FR4 Epoxy Fiberglass Laminate Sheets

Dielectric Performance in High-Frequency Applications

The efficacy of FR4 epoxy fiberglass laminate sheets in high-frequency circuit design hinges on their dielectric properties. A low dielectric constant, typically around 4.5, ensures that signals travel with minimal delay, a crucial factor in applications like radar systems or 5G networks. Equally vital is the low dissipation factor, which curtails energy loss as signals propagate through the PCB. This synergy of attributes mitigates signal attenuation, preserving integrity even at gigahertz frequencies. Designers favor FR4 for its ability to maintain these characteristics across a spectrum of environmental conditions, ensuring consistent performance in devices that demand unerring precision.

Mechanical Resilience for Complex Circuitry

Beyond electrical prowess, FR4 epoxy fiberglass laminate sheets offer exceptional mechanical fortitude. Their woven fiberglass core imparts tensile strength, allowing them to endure the stresses of multilayer PCB fabrication. This resilience is indispensable in high-frequency designs, where intricate layouts often necessitate dense component placement. The sheets resist warping and cracking, even under thermal cycling, which is common in high-speed electronics. This durability translates to longevity, reducing the likelihood of failures in mission-critical systems. Manufacturers of insulating sheets, with decades of expertise, refine these properties to meet the exacting standards of global industries, from aerospace to telecommunications.

Thermal Stability in Demanding Environments

High-frequency circuits often operate in environments that challenge material endurance. FR4 epoxy fiberglass laminate sheets excel here, with a glass transition temperature typically exceeding 130°C. This thermal stability ensures that the material retains its structural integrity and electrical performance under elevated temperatures, a common scenario in high-speed signal processing. The epoxy resin component enhances flame retardancy, meeting stringent safety standards like UL94 V-0. This combination of heat resistance and fire safety makes FR4 an apt choice for applications where reliability is non-negotiable, such as in satellite communications or medical imaging equipment, where consistent operation is paramount.

Applications of FR4 Epoxy Fiberglass Laminate Sheets in High-Frequency Design

Enabling High-Speed Telecommunications

The telecommunications sector thrives on speed and fidelity, domains where FR4 epoxy fiberglass laminate sheets shine. In 5G infrastructure, these sheets underpin PCBs that handle rapid data transmission with minimal latency. Their dielectric consistency ensures that antennas and transceivers maintain signal clarity, crucial for uninterrupted connectivity. The global reach of manufacturers producing these insulating sheets ensures that telecom giants can source materials that meet rigorous performance benchmarks. With over two decades of experience, these producers deliver sheets tailored to the nuanced demands of high-frequency signal propagation, bolstering the backbone of modern communication networks.

Powering Aerospace and Defense Systems

In aerospace and defense, reliability under duress is a non-negotiable criterion. FR4 epoxy fiberglass laminate sheets are integral to PCBs in radar, navigation, and missile guidance systems, where high-frequency signals must traverse without degradation. Their mechanical robustness withstands the vibrations and shocks inherent in flight or combat scenarios, while their thermal stability ensures performance in extreme altitudes or climates. The global supply chain, honed by years of foreign trading expertise, ensures that defense contractors receive materials that adhere to exacting specifications, safeguarding national security through unwavering circuit performance.

Enhancing Consumer Electronics Innovation

The consumer electronics market, driven by innovation, leans heavily on FR4 epoxy fiberglass laminate sheets to push boundaries. Devices like smartphones, wearables, and IoT gadgets rely on compact, high-frequency PCBs to deliver seamless user experiences. The sheets' ability to support dense, multilayer designs allows engineers to pack more functionality into smaller footprints. Their cost-effectiveness, a result of mature manufacturing processes refined over decades, makes FR4 a pragmatic choice for mass production without compromising quality. This balance of performance and economy fuels the rapid evolution of consumer tech, meeting the demands of a global audience.

Choosing the Right FR4 Epoxy Fiberglass Laminate Sheets for Your Project

Assessing Frequency and Performance Needs

Selecting the appropriate FR4 epoxy fiberglass laminate sheets begins with understanding your project's frequency requirements. While standard FR4 excels up to several gigahertz, specialized variants with enhanced dielectric properties cater to ultra-high-frequency applications. Engineers must evaluate the dielectric constant and loss tangent against the operational frequency of their circuits to ensure optimal signal integrity. Manufacturers with extensive experience in insulating sheet production offer detailed datasheets, enabling informed decisions. This meticulous selection process, supported by global expertise, ensures that your PCB performs flawlessly in its intended application, be it a high-speed router or a satellite transponder.

Balancing Cost and Quality

While FR4 epoxy fiberglass laminate sheets are renowned for their cost-effectiveness, quality remains paramount in high-frequency design. Premium grades offer tighter tolerances in dielectric properties and thickness, crucial for precision applications. Conversely, standard grades suffice for less demanding projects, providing a budget-friendly option without sacrificing core functionality. Decades of collaboration with domestic and international trading partners enable manufacturers to offer a spectrum of grades, catering to diverse needs. This flexibility ensures that designers can strike an equilibrium between expenditure and performance, aligning with project goals without compromising reliability.

Partnering with Experienced Suppliers

The success of high-frequency circuit design often hinges on the quality of materials sourced. Partnering with a supplier boasting over 20 years of experience in insulating sheet production and a decade in global trade guarantees access to top-tier FR4 epoxy fiberglass laminate sheets. Such suppliers, with their extensive network, provide not just materials but also technical support, ensuring that your project benefits from their accrued expertise. Their ability to deliver consistent, high-quality sheets, backed by perfect service, empowers designers to innovate confidently, knowing that their foundational materials are of unimpeachable standard.

Conclusion

FR4 epoxy fiberglass laminate sheets are indispensable in high-frequency circuit design, blending dielectric excellence, mechanical robustness, and thermal stability. From telecommunications to aerospace, their versatility empowers innovation across industries. By understanding their properties, exploring their applications, and selecting the right grade, designers can harness their full potential. With the backing of experienced manufacturers, these sheets ensure that high-speed circuits perform reliably, meeting the demands of a connected world. Choose wisely, and let FR4 be the cornerstone of your next groundbreaking design.

Contact Us

If you're looking for high-quality FR4 epoxy fiberglass laminate sheets for your high-frequency circuit design needs, look no further. With over 20 years of experience in producing and selling insulating sheets, we offer expert knowledge and superior products to meet your requirements. Contact us today at info@jhd-material.com to learn more about our FR4 laminates and how we can support your project's success.

References

1. "Dielectric Materials for High-Frequency PCB Design," Journal of Electronic Materials, Volume 48, Issue 3, 2019.

2. "Thermal and Mechanical Properties of Epoxy-Based Laminates," Composites Science and Technology, Volume 79, 2013.

3. "Signal Integrity in High-Speed Circuitry," IEEE Transactions on Microwave Theory and Techniques, Volume 67, Issue 5, 2019.

4. "Advanced PCB Substrates for Aerospace Applications," International Journal of Aerospace Engineering, Volume 2020, Article ID 5478921.

5. "Flame Retardancy in Electronic Materials," Polymer Degradation and Stability, Volume 95, Issue 9, 2010.

6. "Cost-Effective Materials for Consumer Electronics PCBs," Electronics Manufacturing Review, Volume 12, Issue 4, 2018.