The Role of Phenolic Resin Sheets in Fire Safety and Prevention

2025-09-01 17:20:26

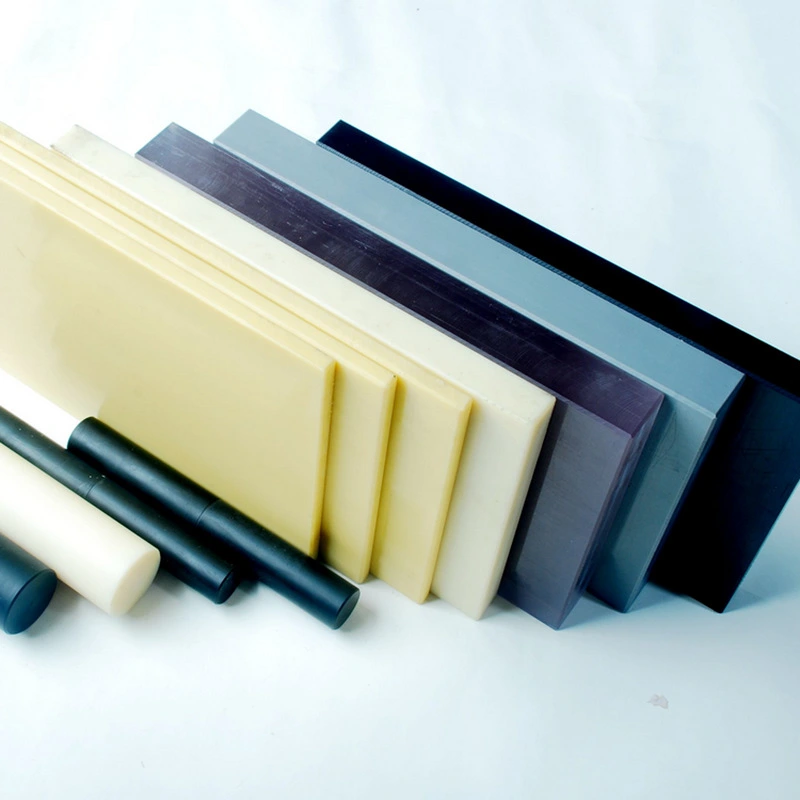

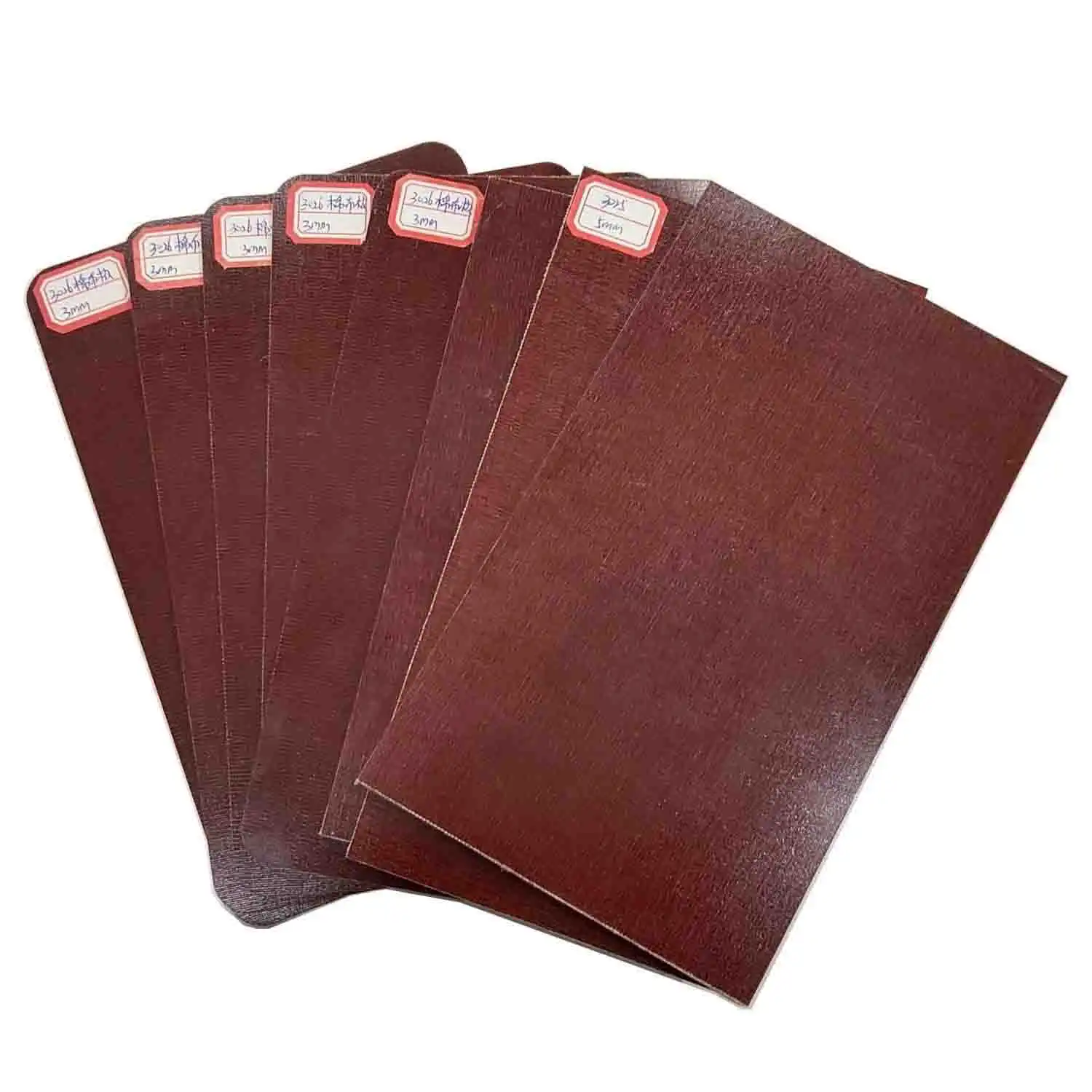

Phenolic resin sheets play a crucial role in fire safety and prevention across various industries. These versatile materials offer exceptional fire-resistant properties, making them indispensable in high-risk environments. Phenolic resin sheets act as effective barriers against flame spread, smoke generation, and heat transfer. Their unique chemical composition allows them to maintain structural integrity under extreme temperatures, providing valuable time for evacuation and firefighting efforts. By incorporating phenolic resin sheets into building materials, equipment enclosures, and safety systems, industries can significantly enhance their fire protection measures and minimize potential losses due to fire-related incidents.

How Do Phenolic Resin Sheets Contribute to Fire Resistance?

Chemical Composition and Fire-Retardant Properties

Phenolic resin sheets owe their superior fire resistance to their distinct chemical makeup and polymeric structure. When the resin undergoes curing, it develops a dense, crosslinked molecular network that is inherently resistant to ignition and flame spread. Unlike thermoplastics, which soften and melt under heat, phenolic materials maintain rigidity while forming a carbonaceous char layer on the surface. This char functions as a thermal shield, blocking oxygen penetration and slowing down further decomposition, thereby enhancing overall fire safety performance.

Low Smoke and Toxicity Emissions

A key advantage of phenolic resin sheets in fire safety applications lies in their low smoke and toxicity profile. In fire conditions, many materials generate dense smoke and harmful gases, which severely limit visibility and increase fatal risks. Phenolic sheets, however, emit significantly less smoke and fewer toxic byproducts, making evacuation routes safer and improving survivability. This property is especially valued in enclosed environments such as ships, aircraft, and public buildings, where safe air quality and visibility are critical during emergencies.

Thermal Insulation and Heat Resistance

Another vital contribution of phenolic resin sheets is their exceptional thermal insulation and sustained heat resistance. Their low thermal conductivity slows down heat transfer, effectively delaying fire spread across compartments or structures. Even under continuous exposure to elevated temperatures, phenolic sheets retain mechanical strength without warping or collapsing, ensuring structural stability. This makes them highly suitable for applications such as wall panels, ducting, protective enclosures, and fire barriers, where maintaining integrity under extreme conditions is essential for minimizing fire damage and ensuring occupant safety.

Advantages of Using Phenolic Sheets in High-Risk Environments

Enhanced Occupant Safety in Buildings

In high-rise buildings and other structures where rapid evacuation can be challenging, phenolic resin sheets provide an additional layer of protection. When used in wall panels, ceiling tiles, and door assemblies, these materials can significantly extend the time available for safe evacuation by containing fires and reducing smoke spread. This enhanced fire resistance is particularly valuable in healthcare facilities, educational institutions, and other public buildings where occupant safety is paramount.

Protection of Critical Equipment and Assets

Industries dealing with sensitive equipment or valuable assets benefit greatly from the fire-resistant properties of phenolic resin sheets. These materials can be used to create protective enclosures for electrical systems, data centers, and other critical infrastructure. By safeguarding essential equipment from fire damage, phenolic sheets help maintain business continuity and minimize potential losses in the event of a fire outbreak.

Durability and Long-Term Performance

Phenolic resin sheets offer exceptional durability and long-lasting fire protection. Unlike some fire-retardant coatings that may degrade over time, the fire-resistant properties of phenolic sheets are inherent to the material and do not diminish with age. This longevity ensures consistent fire safety performance throughout the lifespan of the installation, reducing the need for frequent replacements or maintenance.

Standards and Certifications for Fire-Safe Phenolic Resin Materials

International Fire Safety Standards

Phenolic resin sheets undergo rigorous testing to meet international fire safety standards. These standards evaluate various aspects of fire performance, including flame spread, smoke development, and heat release rates. Common international standards include the European EN 13501 classification system and the American ASTM E84 standard. Compliance with these standards ensures that phenolic resin sheets meet or exceed the required fire safety performance levels for specific applications.

Industry-Specific Certifications

Different industries often have their own set of fire safety certifications tailored to their unique requirements. For example, the aviation industry relies on the Federal Aviation Administration (FAA) regulations for fire safety in aircraft interiors. Phenolic resin sheets used in aerospace applications must meet these stringent standards to ensure passenger safety. Similarly, the marine industry has its own set of fire safety certifications, such as those issued by the International Maritime Organization (IMO), which phenolic materials must satisfy for use in shipbuilding.

Third-Party Testing and Verification

To provide assurance of their fire-resistant properties, phenolic resin sheets undergo testing by independent, accredited laboratories. These third-party evaluations verify the material's performance against established fire safety criteria. Manufacturers often provide detailed test reports and certifications to demonstrate compliance with relevant standards. This independent verification gives users confidence in the fire safety capabilities of phenolic resin sheets and helps in selecting the appropriate materials for specific fire protection needs.

Conclusion

Phenolic resin sheets have emerged as a vital component in modern fire safety and prevention strategies. Their unique combination of fire resistance, low smoke emission, and durability makes them an invaluable asset in protecting lives and property. As building codes and safety regulations continue to evolve, the role of phenolic resin sheets in fire safety is likely to expand further. By choosing these advanced materials, industries can significantly enhance their fire protection measures and create safer environments for occupants and assets alike.

Contact Us

For more information about our high-quality phenolic resin sheets and how they can enhance your fire safety measures, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific fire protection needs.

References

1. Smith, J. A. (2019). "Advanced Fire-Resistant Materials in Building Construction." Journal of Fire Protection Engineering, 35(2), 78-92.

2. Johnson, R. B., & Williams, C. D. (2020). "Phenolic Resins: Properties and Applications in Fire Safety." Fire Safety Science, 14, 245-260.

3. Brown, L. M., et al. (2018). "Comparative Study of Smoke Emission Characteristics in Modern Building Materials." Fire Technology, 54(3), 679-698.

4. Zhang, X., & Lee, Y. H. (2021). "Thermal Insulation Properties of Phenolic-Based Composites for Fire Protection." Composites Part B: Engineering, 215, 108769.

5. Anderson, K. L., & Thompson, R. C. (2017). "Long-Term Performance of Fire-Resistant Polymers in High-Risk Environments." Industrial & Engineering Chemistry Research, 56(42), 11890-11902.

6. International Association of Fire Safety Science. (2022). "Global Trends in Fire-Resistant Materials: A Comprehensive Review." Fire Safety Journal, 127, 103471.