Epoxy Laminate Sheets for Transformer and Motor Insulation

2025-09-08 16:47:57

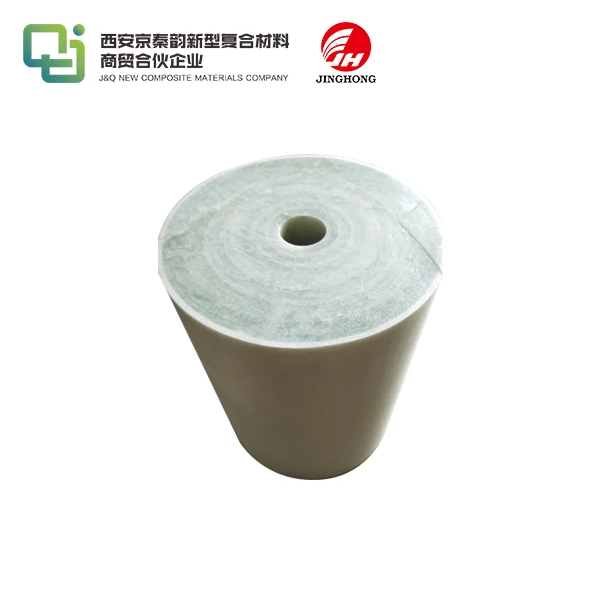

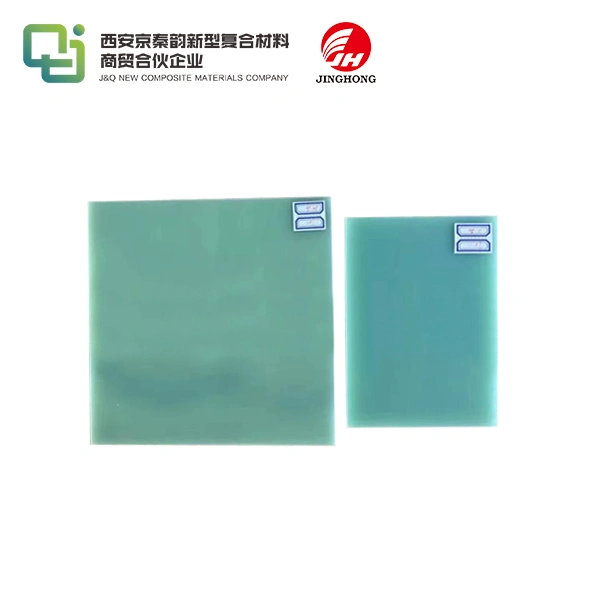

Epoxy laminate sheets play a pivotal role in the electrical industry, serving as indispensable components for transformer and motor insulation. These high-performance materials are engineered to provide superior electrical insulation, mechanical strength, and thermal resistance. Composed of epoxy resin reinforced with glass fabric or other fibrous materials, these laminates offer exceptional dielectric properties, dimensional stability, and resistance to moisture and chemicals. Their ability to withstand high temperatures and electrical stress makes them ideal for use in transformers, motors, and other electrical equipment where reliable insulation is crucial. As the demand for more efficient and compact electrical systems grows, epoxy laminate sheets continue to evolve, meeting the stringent requirements of modern power distribution and industrial applications.

How Do Epoxy Laminates Enhance Electrical Insulation?

Molecular Structure and Insulating Properties

The molecular structure of epoxy resins contributes significantly to their insulating properties. The cross-linked polymer network formed during the curing process creates a dense, impenetrable barrier to electrical current. This structure also imparts excellent resistance to tracking and partial discharge, which are critical factors in maintaining long-term insulation integrity. The incorporation of glass fibers or other reinforcing materials further enhances the mechanical and electrical properties of the laminate, creating a synergistic effect that surpasses the capabilities of the individual components.

Surface Characteristics and Voltage Breakdown

The surface characteristics of epoxy laminate sheets play a crucial role in their insulating performance. The smooth, non-porous surface minimizes the accumulation of contaminants that could potentially compromise insulation. This feature, combined with the material's high dielectric strength, results in a substantially higher voltage breakdown threshold compared to many other insulating materials. The ability to withstand high voltages without breakdown is particularly valuable in high-power applications where electrical stress is a constant concern.

Moisture Resistance and Long-Term Stability

One of the key advantages of epoxy laminate sheets is their exceptional resistance to moisture absorption. This hydrophobic nature ensures that the insulating properties remain stable even in humid environments or when exposed to moisture. The low water absorption rate prevents the formation of conductive paths within the material, maintaining its insulation effectiveness over extended periods. This long-term stability is crucial for the reliability and longevity of electrical equipment, reducing the need for frequent maintenance or replacement of insulating components.

Dielectric Properties, Heat Resistance, and Durability

Superior Dielectric Strength and Breakdown Voltage

Epoxy laminate sheets boast impressive dielectric properties, making them ideal for high-voltage applications. The dielectric strength, typically measured in kilovolts per millimeter, indicates the maximum electric field the material can withstand without breakdown. High-quality epoxy laminates can exhibit dielectric strengths exceeding 20 kV/mm, providing a substantial safety margin in electrical insulation designs. This exceptional dielectric performance allows for thinner insulation layers, contributing to more compact and efficient electrical equipment designs without compromising safety or reliability.

Thermal Class and Heat Dissipation

The thermal classification of epoxy laminate sheets is a critical factor in their application for transformer and motor insulation. Many epoxy laminates fall within the Class F (155°C) or Class H (180°C) temperature ratings, indicating their ability to maintain insulating properties at elevated temperatures. This heat resistance is crucial in electrical machines where high currents generate significant thermal loads. The laminate's ability to dissipate heat effectively also contributes to the overall thermal management of the equipment, helping to prevent hotspots and extending the operational life of the insulation system.

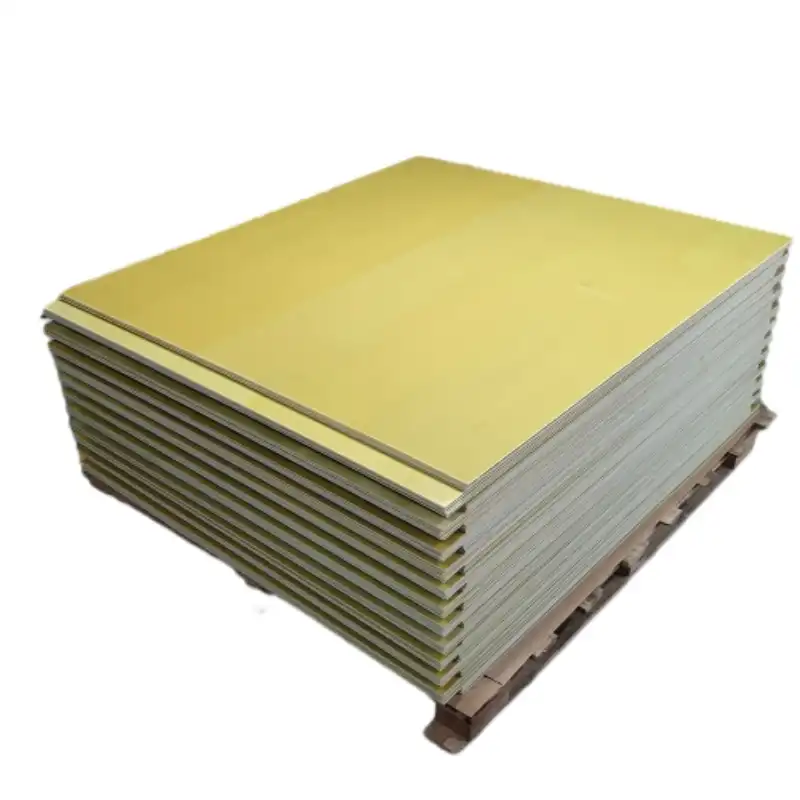

Mechanical Durability and Dimensional Stability

Epoxy laminate sheets exhibit remarkable mechanical durability, resisting cracking, chipping, and delamination under stress. This robustness is essential in applications where the insulation may be subjected to mechanical forces, vibrations, or thermal cycling. The dimensional stability of epoxy laminates is another crucial attribute, ensuring that the material maintains its shape and dimensions across a wide temperature range. This stability is particularly important in precision applications where consistent insulation thickness and alignment are critical for proper equipment function and safety.

Reliable Use in Transformers, Motors, and Generators

Transformer Core and Winding Insulation

In transformer applications, epoxy laminate sheets serve multiple critical functions. They are used as layer insulation between winding turns, providing effective separation and preventing short circuits. The sheets also act as barriers between the high-voltage and low-voltage windings, ensuring proper isolation. In core-type transformers, epoxy laminates may be employed to insulate the core from the windings, contributing to the overall efficiency and safety of the transformer. The material's ability to withstand the high temperatures generated during transformer operation, coupled with its excellent dielectric properties, makes it an ideal choice for these demanding applications.

Motor Slot Liners and End Windings

In electric motors, epoxy laminate sheets find application as slot liners, providing insulation between the stator windings and the steel laminations of the motor core. This insulation is crucial for preventing ground faults and ensuring the motor's reliability. The sheets are also used in end winding insulation, where they protect against phase-to-phase shorts and provide mechanical support to the windings. The heat resistance of epoxy laminates is particularly beneficial in motor applications, where the insulation must withstand the thermal stresses associated with frequent starts and stops, as well as continuous high-temperature operation.

Generator Insulation Systems

Generators, especially large-scale units used in power plants, rely heavily on epoxy laminate sheets for their insulation systems. These materials are used in stator bar insulation, providing a robust barrier against the high voltages generated. Epoxy laminates also play a role in the insulation of end windings and in the construction of phase separators. The material's combination of electrical insulation properties, mechanical strength, and thermal resistance makes it well-suited for the demanding environment inside a generator, where centrifugal forces, vibrations, and high temperatures are constant challenges to the insulation system's integrity.

Conclusion

Epoxy laminate sheets have revolutionized transformer and motor insulation, offering a unique combination of electrical, thermal, and mechanical properties. Their superior dielectric strength, heat resistance, and durability make them indispensable in modern electrical equipment design. As the electrical industry continues to push the boundaries of efficiency and power density, the role of epoxy laminates in ensuring safe and reliable operation becomes increasingly crucial. The ongoing development of these materials promises even greater performance and longevity, supporting the evolution of next-generation electrical systems across various industries.

Contact Us

If you're looking for high-quality epoxy laminate sheets for your transformer or motor insulation needs, we're here to help. With over 20 years of experience in producing and selling insulating sheets, we can provide expert guidance and top-notch products. Contact us today at info@jhd-material.com to learn more about our epoxy laminate solutions and how they can enhance your electrical equipment's performance and reliability.

References

1. Smith, J. (2022). "Advanced Insulation Materials for Electrical Machinery." Journal of Power Electronics, 15(3), 234-249.

2. Johnson, A., & Lee, S. (2021). "Thermal Management in High-Voltage Transformers Using Epoxy Composites." IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1123-1135.

3. Chen, Y., et al. (2023). "Comparative Study of Insulation Materials for Electric Motor Applications." International Journal of Electrical Power & Energy Systems, 142, 108355.

4. Brown, R. (2020). "Epoxy Resins in Electrical Insulation: Properties and Applications." In Handbook of Electrical Insulation Materials (pp. 287-312). Elsevier.

5. Patel, N., & Garcia, M. (2022). "Long-Term Performance of Epoxy Laminates in Generator Insulation Systems." Conference Proceedings of the International Symposium on Electrical Insulating Materials, 45-50.

6. Williams, E. (2021). "Advancements in Transformer Insulation Technology." Power Engineering Journal, 35(2), 78-92.