What Makes Phenolic Cotton Sheets Ideal for Gears and Bearings?

2025-09-15 17:09:55

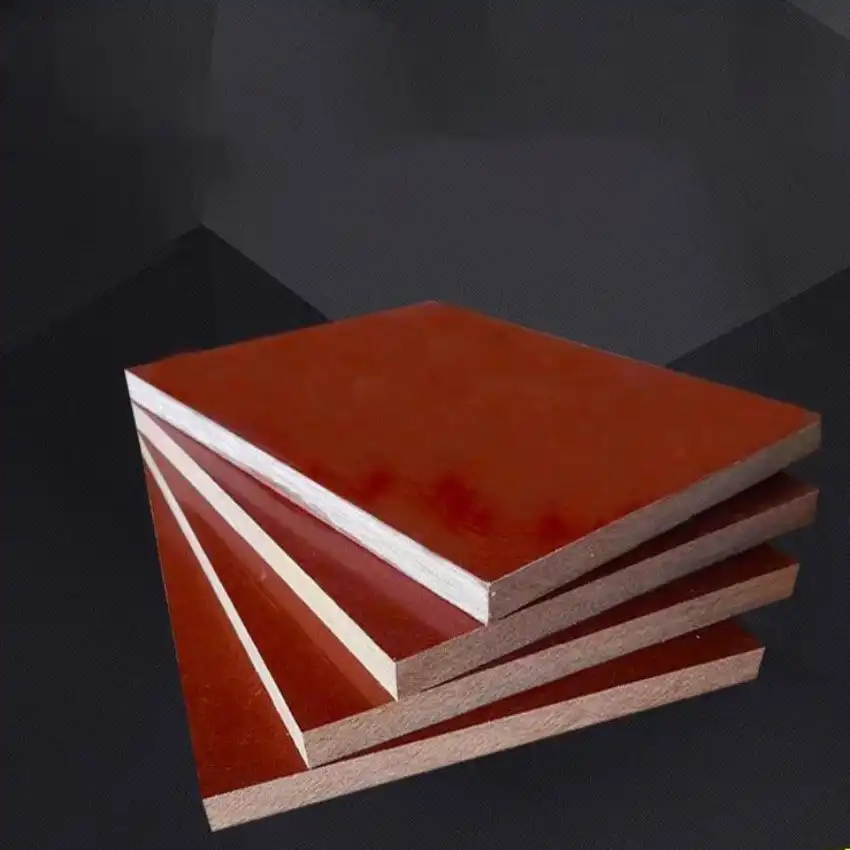

Phenolic cotton sheets stand out as an exceptional choice for gears and bearings due to their unique combination of properties. These composite materials offer remarkable mechanical strength, excellent wear resistance, and superior thermal stability. Their ability to maintain dimensional stability under varying loads and temperatures, coupled with inherent self-lubricating properties, makes them ideal for high-performance moving parts. Additionally, phenolic cotton sheets exhibit low friction coefficients and impressive chemical resistance, ensuring longevity and reliability in demanding industrial applications.

Mechanical Strength and Wear Resistance Characteristics

Impressive Tensile and Compressive Strength

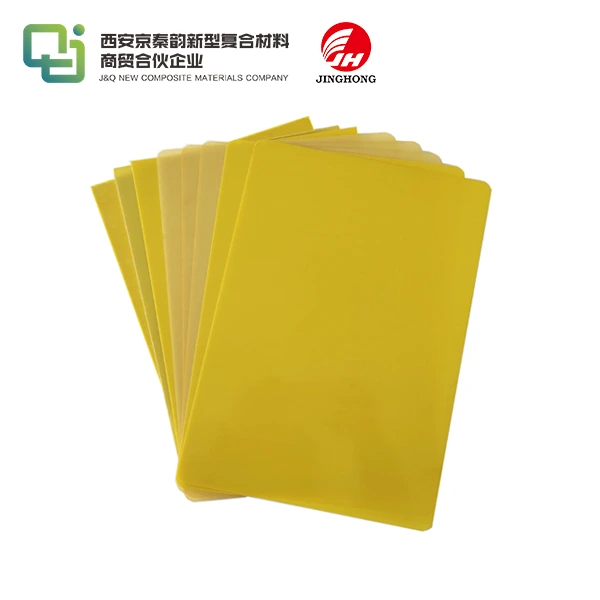

Phenolic cotton sheets are engineered to deliver outstanding mechanical performance, especially in tensile and compressive strength. The combination of phenolic resin and woven cotton layers creates a tough composite that can endure heavy static and dynamic loads. This strength is achieved without adding excessive weight, giving the material a favorable strength-to-weight ratio. As a result, phenolic cotton sheets are widely chosen for demanding gear and bearing applications where both structural integrity and lightweight properties are essential for efficient operation.

Superior Wear Resistance

Another defining advantage of phenolic cotton sheets is their excellent wear resistance, which ensures long-term durability even in harsh mechanical environments. The cross-linked phenolic resin structure, reinforced with cotton fibers, provides a dense and resilient material surface. This composition significantly reduces frictional wear, even under constant stress and repetitive motion. Such properties make phenolic cotton sheets highly suitable for gears, bearings, and similar components, where continuous contact and sliding could otherwise lead to rapid material degradation and performance loss.

Dimensional Stability Under Load

Phenolic cotton sheets also exhibit impressive dimensional stability, retaining their shape and integrity under sustained pressure or mechanical stress. This property is particularly important in precision applications, where accurate alignment and minimal distortion are critical to smooth operation. By resisting deformation, these sheets help prevent issues such as misalignment, uneven load distribution, and irregular wear. Their ability to maintain reliable geometry under load directly enhances the overall performance, operational efficiency, and service life of gears, bearings, and other mechanical components.

Thermal Stability and Lubrication Compatibility

High Temperature Resistance

Phenolic cotton sheets are designed to deliver outstanding thermal stability, maintaining their mechanical integrity across a wide spectrum of operating temperatures. In demanding applications such as gears and bearings, heat generation from friction is unavoidable, yet these sheets resist thermal degradation effectively. They retain tensile strength, compressive resistance, and durability even under continuous exposure to elevated temperatures. This high temperature resistance ensures that components perform consistently under stress, minimizing downtime and extending service life in mechanical systems where heat management is critical.

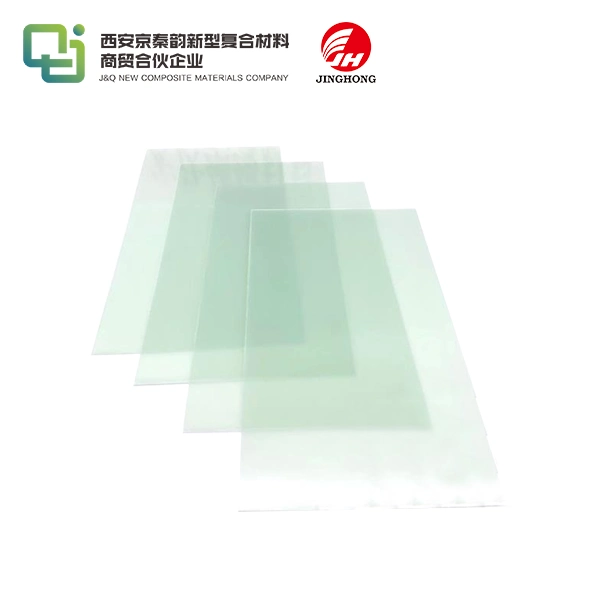

Low Thermal Expansion

Another important property of phenolic cotton sheets is their low coefficient of thermal expansion, which helps maintain precise dimensional accuracy under changing temperatures. Unlike materials that expand or contract significantly, phenolic cotton sheets remain stable, preserving critical clearances and tolerances. This characteristic is essential in gears and bearings where misalignment or binding caused by expansion can lead to premature wear and mechanical failure. By minimizing dimensional changes, the material contributes to smooth, predictable performance and enhances overall reliability in precision-driven applications.

Compatibility with Lubricants

Phenolic cotton sheets also demonstrate exceptional compatibility with a wide range of lubricants, including oils and greases commonly used in mechanical systems. This property enhances the material’s inherent wear resistance by reducing surface friction and preventing excessive heat buildup during operation. The ability to integrate seamlessly with lubrication strategies not only extends the lifespan of gears and bearings but also improves system efficiency. With reliable lubricant compatibility, phenolic cotton components maintain consistent performance under diverse operating conditions, making them a trusted choice for high-demand environments.

Typical Industrial Applications in Moving Parts

High-Performance Gears

Phenolic cotton sheets are frequently used in the manufacture of high-performance gears across various industries. Their combination of strength, wear resistance, and dimensional stability makes them particularly suitable for applications where traditional metal gears may fall short. These gears find use in heavy machinery, automotive components, and industrial equipment where reliability and longevity are critical factors. The material's inherent damping properties also contribute to quieter operation, an added benefit in many applications.

Durable Bearings and Bushings

The exceptional wear resistance and low friction characteristics of phenolic cotton sheets make them an excellent choice for bearings and bushings. These components are often used in applications where traditional metal bearings may be prone to premature wear or require frequent lubrication. Phenolic cotton bearings offer extended service life, reduced maintenance requirements, and improved performance in challenging environments, such as those with exposure to corrosive substances or extreme temperatures.

Specialized Mechanical Components

Beyond gears and bearings, phenolic cotton sheets find application in a variety of specialized mechanical components. These may include wear plates, guide rails, and custom-designed parts for specific industrial machinery. The material's versatility allows for the creation of complex shapes and geometries through machining processes, enabling engineers to develop innovative solutions for challenging mechanical design problems. The combination of strength, wear resistance, and thermal stability makes phenolic cotton sheets a go-to material for components that must perform reliably under demanding conditions.

Conclusion

Phenolic cotton sheets emerge as an ideal material for gears, bearings, and other critical moving parts due to their exceptional mechanical properties, thermal stability, and wear resistance. Their ability to maintain dimensional integrity under varying loads and temperatures, coupled with excellent lubrication compatibility, ensures reliable performance in demanding industrial applications. As engineers continue to seek materials that offer enhanced durability and efficiency, phenolic cotton sheets stand out as a versatile and high-performing option for a wide range of mechanical components.

Contact Us

For more information about our phenolic cotton sheets and how they can benefit your specific application, please contact us at info@jhd-material.com. As a trusted phenolic cotton sheet factory, our team of experts is ready to assist you in finding the perfect solution for your mechanical engineering needs.

References

1. Johnson, R. M. (2019). Advanced Composite Materials in Modern Engineering Applications. Elsevier Science.

2. Thompson, L. K. (2020). Phenolic Resins: A Century of Progress. Springer International Publishing.

3. Williams, G. H. (2018). Handbook of Engineering Polymeric Materials. CRC Press.

4. Chen, X., & Liu, Y. (2021). Tribology of Polymer Composites: Fundamentals and Applications. Wiley-VCH.

5. Davis, J. R. (2017). Gear Materials, Properties, and Manufacture. ASM International.

6. Harnoy, A. (2019). Bearing Design in Machinery: Engineering Tribology and Lubrication. CRC Press.