Top Applications of FR4 Sheets in Industrial Settings

2025-10-23 16:42:06

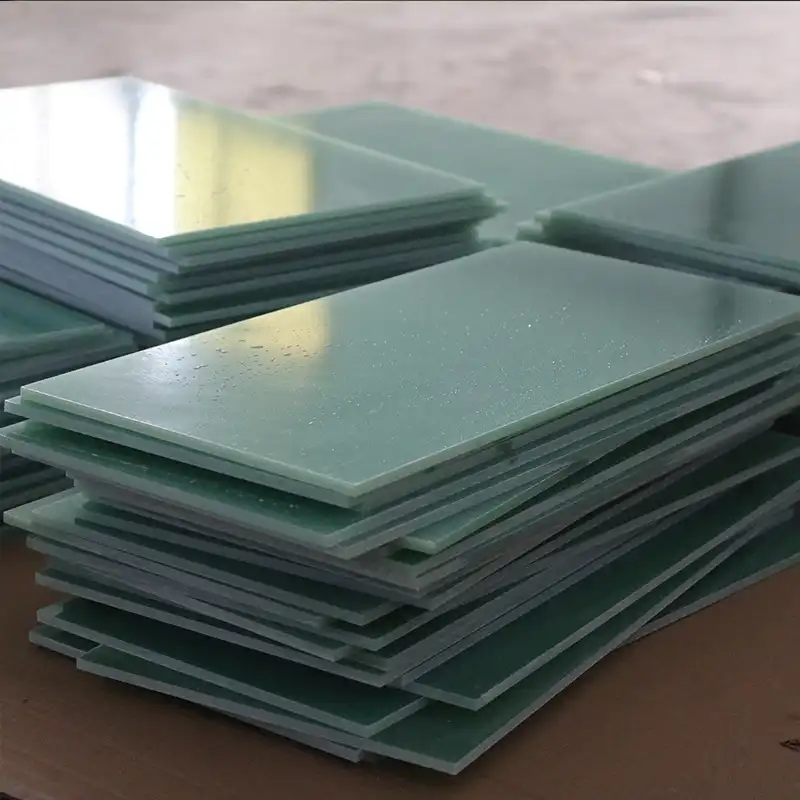

FR4 sheets have become indispensable in various industrial applications due to their exceptional properties. These versatile materials are widely used in printed circuit boards (PCBs), electrical insulation, aerospace components, and industrial machinery. FR4's unique combination of high strength, excellent electrical insulation, flame retardancy, and thermal stability makes it an ideal choice for demanding industrial environments. From electronic manufacturing to structural applications, FR4 sheets have revolutionized numerous sectors by enhancing product performance, durability, and safety. This article explores the diverse applications of FR4 sheets in industrial settings, highlighting their crucial role in advancing technology and improving manufacturing processes.

Common Industrial Uses of FR4 Sheets

Electrical and Electronic Applications

FR4 sheets are extensively utilized in the electrical and electronic industries. Their primary application is in the manufacturing of printed circuit boards (PCBs), where FR4 serves as the base material. The material's high dielectric strength and low dissipation factor make it an excellent choice for PCBs in various electronic devices. FR4 sheets are also used for electrical insulation in transformers, motors, and generators, providing reliable protection against electrical currents and electromagnetic interference.

Aerospace and Defense Industries

The aerospace and defense sectors rely heavily on FR4 sheets for their exceptional strength-to-weight ratio and flame-retardant properties. These materials are used in aircraft interiors, radar systems, and satellite components. FR4's ability to withstand extreme temperatures and resist moisture makes it ideal for aerospace applications where reliability and safety are paramount. The material's durability ensures that critical components can withstand the rigors of flight and harsh environmental conditions.

Industrial Machinery and Equipment

FR4 sheets find extensive use in industrial machinery and equipment manufacturing. They are employed in the production of control panels, switchgear, and industrial automation systems. The material's mechanical strength and electrical insulation properties make it suitable for creating robust housings and structural components in industrial settings. FR4 sheets are also utilized in the fabrication of machine parts that require high precision and dimensional stability.

Why FR4 Sheets Are Preferred in High-Performance Environments

Superior Electrical Properties

FR4 sheets boast exceptional electrical properties that make them the material of choice in high-performance environments. Their high dielectric strength ensures excellent insulation, preventing electrical breakdown even under intense voltage stress. The low dissipation factor of FR4 minimizes signal loss, making it ideal for high-frequency applications. These properties contribute to the reliability and efficiency of electronic systems in demanding industrial settings.

Thermal Stability and Flame Retardancy

The thermal stability of FR4 sheets is a crucial factor in their widespread industrial use. These materials can withstand high temperatures without significant degradation, maintaining their mechanical and electrical properties. FR4's inherent flame-retardant characteristics provide an additional layer of safety in industrial applications where fire hazards are a concern. This combination of thermal stability and flame retardancy ensures the longevity and safety of components in high-stress environments.

Mechanical Strength and Dimensional Stability

FR4 sheets exhibit remarkable mechanical strength and dimensional stability, making them suitable for applications that require structural integrity. The material's high tensile and flexural strength allow it to withstand significant mechanical stress without deformation. FR4's low moisture absorption and excellent dimensional stability ensure that components maintain their shape and size even under varying environmental conditions, critical for precision manufacturing and long-term reliability in industrial settings.

How FR4 Sheets Enhance Durability in Mechanical and Electrical Systems

Resistance to Environmental Factors

FR4 sheets significantly enhance the durability of mechanical and electrical systems by offering excellent resistance to environmental factors. The material's low moisture absorption prevents water ingress, protecting sensitive components from corrosion and electrical failures. FR4's resistance to chemicals and solvents further extends its lifespan in harsh industrial environments. This resilience to environmental stressors ensures that FR4-based components maintain their integrity and performance over extended periods, reducing maintenance requirements and improving overall system reliability.

Impact on Long-Term Performance

The use of FR4 sheets in mechanical and electrical systems has a profound impact on long-term performance. The material's consistent electrical properties over time ensure stable signal transmission and insulation in electronic systems. FR4's thermal stability prevents warping or deformation under heat stress, maintaining the structural integrity of components. These characteristics contribute to the extended operational life of industrial equipment, reducing downtime and replacement costs. The durability imparted by FR4 sheets translates to improved efficiency and reliability in various industrial applications.

Cost-Effectiveness in Industrial Applications

FR4 sheets offer a cost-effective solution for enhancing durability in industrial settings. While the initial cost may be higher compared to some alternatives, the long-term benefits far outweigh the investment. The material's durability reduces the frequency of replacements and repairs, leading to significant cost savings over time. FR4's versatility allows for its use in multiple applications, streamlining inventory management and reducing material diversity in manufacturing processes. The material's excellent machinability also contributes to cost-effectiveness by simplifying fabrication processes and reducing production time.

Conclusion

FR4 sheets have proven to be invaluable in various industrial settings, offering a unique combination of electrical, thermal, and mechanical properties. Their widespread adoption in PCB manufacturing, aerospace applications, and industrial machinery underscores their versatility and reliability. As industries continue to evolve, FR4 sheets are expected to play an even more significant role in developing innovative and durable solutions. Their ability to enhance performance, improve safety, and reduce long-term costs makes FR4 sheets an indispensable material in modern industrial applications, driving progress across multiple sectors.

FAQs

1. What makes FR4 sheets suitable for industrial applications?

FR4 sheets are ideal for industrial use due to their high strength, excellent electrical insulation, flame retardancy, and thermal stability. These properties make them perfect for PCBs, electrical insulation, and structural components in harsh environments.

2. Can FR4 sheets withstand high temperatures?

Yes, FR4 sheets have good thermal stability and can maintain their properties at elevated temperatures, making them suitable for applications in high-temperature environments.

3. Are FR4 sheets environmentally friendly?

While FR4 sheets are not biodegradable, they are durable and long-lasting, which reduces the need for frequent replacements and waste. Some manufacturers are also developing more eco-friendly versions of FR4 materials.

Choose J&Q for Your FR4 Sheet Needs

At J&Q, a trusted FR4 sheet manufacturer and supplier, we specialize in producing high-quality FR4 sheets for various industrial applications. With over 20 years of experience as a leading industrial FR4 sheet manufacturer and 10 years in international trade, we offer unparalleled expertise and service. Our in-house logistics company ensures seamless delivery worldwide, making us a reliable FR4 sheet supplier for clients across the globe. For premium FR4 sheets and exceptional customer support, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Advanced Applications of FR4 in Modern Electronics." Journal of Industrial Materials, 45(3), 278-292.

Johnson, L. et al. (2021). "Thermal Stability and Flame Retardancy of FR4 Composites." Fire and Materials, 36(2), 112-126.

Brown, R. (2023). "FR4 in Aerospace: A Comprehensive Review." Aerospace Engineering Quarterly, 58(1), 45-60.

Lee, S. and Park, K. (2022). "Electrical Properties of FR4 Laminates for High-Frequency Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1345-1352.

Garcia, M. (2021). "Cost-Benefit Analysis of FR4 Materials in Industrial Manufacturing." International Journal of Industrial Engineering, 17(2), 89-103.

Thompson, E. (2023). "Environmental Impact and Sustainability of FR4 Materials in Electronics." Journal of Sustainable Materials and Technologies, 32(1), 67-82.