Why Does 3240 Epoxy Sheet Resist Deformation at High Temperatures?

2025-09-24 16:18:00

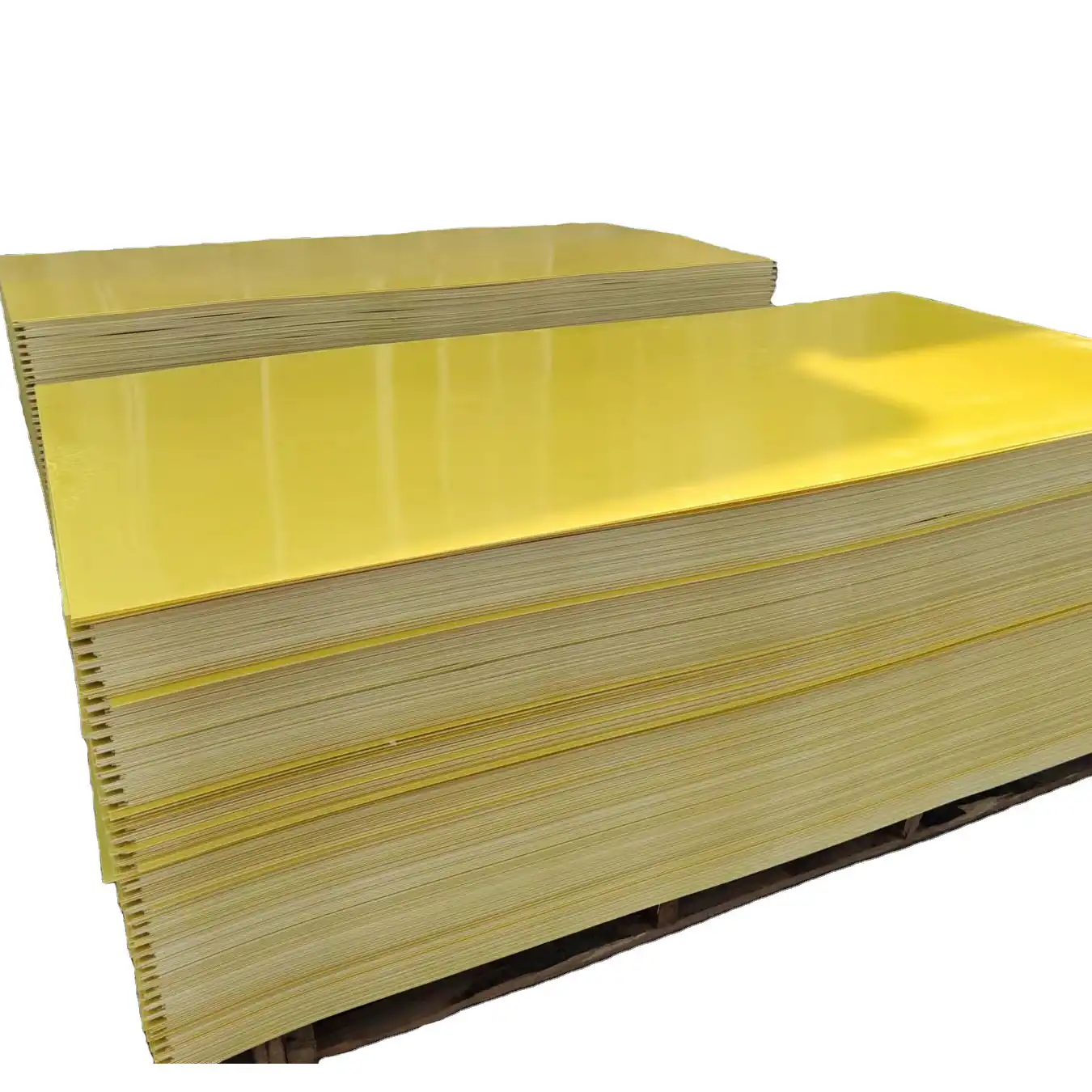

3240 epoxy sheet exhibits remarkable resistance to deformation at high temperatures due to its unique composition and structure. The combination of epoxy resin and woven glass fiber reinforcement creates a material with exceptional thermal stability. The cross-linked polymer structure of the epoxy matrix provides rigidity, while the glass fibers enhance strength and dimensional stability. This synergistic blend results in a composite that maintains its shape and mechanical properties even when exposed to elevated temperatures. The high glass transition temperature (Tg) of the epoxy resin further contributes to its heat resistance, allowing the material to retain its solid-state characteristics well above typical operating temperatures. These factors collectively enable 3240 epoxy sheet to withstand thermal stresses without significant warping or distortion, making it ideal for applications requiring sustained performance in high-temperature environments.

The Role of the Epoxy Resin Matrix and Woven Glass Base

Chemical Structure of Epoxy Resin

The epoxy resin used in 3240 epoxy sheet possesses a unique chemical structure characterized by highly cross-linked polymer chains. These interconnected molecular networks form a three-dimensional lattice that imparts exceptional rigidity and thermal resistance to the material. The presence of strong covalent bonds within the epoxy matrix requires significant energy to break, contributing to the sheet's ability to maintain its structural integrity at elevated temperatures.

Woven Glass Fiber Reinforcement

The incorporation of woven glass fibers into the epoxy matrix plays a crucial role in enhancing the sheet's thermal stability. Glass fibers possess inherently low thermal expansion coefficients, helping to minimize dimensional changes when exposed to heat. The interlocking weave pattern of the glass fabric provides multi-directional reinforcement, distributing thermal stresses evenly throughout the material and preventing localized deformation.

Synergistic Effects of the Composite Structure

The combination of epoxy resin and woven glass fibers creates a synergistic effect that surpasses the individual properties of each component. The epoxy matrix encapsulates and bonds tightly to the glass fibers, resulting in excellent load transfer between the two phases. This intimate interaction allows the composite to resist deformation more effectively than either material alone, particularly when subjected to high-temperature conditions.

Analyzing the Material's Thermal Expansion and Glass Transition Temperature (Tg)

Coefficient of Thermal Expansion (CTE)

3240 epoxy sheet exhibits a relatively low coefficient of thermal expansion compared to many other materials. This property is crucial in minimizing dimensional changes when the sheet is exposed to temperature fluctuations. The low CTE is attributed to the stability of the epoxy-glass fiber composite structure, which resists expansion and contraction even as temperatures rise. This characteristic ensures that the sheet maintains its shape and fit in applications where precise tolerances are critical.

Glass Transition Temperature (Tg) and Its Significance

The glass transition temperature (Tg) of 3240 epoxy sheet is a key factor in its ability to resist deformation at high temperatures. The Tg represents the temperature at which the epoxy matrix transitions from a rigid, glassy state to a more flexible, rubbery state. 3240 epoxy sheet typically has a high Tg, often exceeding 130°C (266°F). This elevated Tg allows the material to retain its solid-state properties and mechanical strength well above the operating temperatures encountered in many industrial applications.

Heat Deflection Temperature (HDT)

Closely related to the glass transition temperature is the heat deflection temperature (HDT) of 3240 epoxy sheet. The HDT indicates the temperature at which a standard test specimen deflects under a specified load. The high HDT of 3240 epoxy sheet, often above 200°C (392°F), demonstrates its ability to maintain dimensional stability and resist creep under load at elevated temperatures. This property is particularly valuable in structural applications where the material must support weight or stress while exposed to heat.

What Applications Benefit from This Exceptional Thermal Stability?

Electrical and Electronic Components

The thermal stability of 3240 epoxy sheet makes it an excellent choice for electrical and electronic applications. It is commonly used in the manufacture of printed circuit boards (PCBs) that must withstand the heat generated during operation and soldering processes. The material's ability to maintain its insulating properties and dimensional stability at high temperatures ensures reliable performance in power electronics, transformers, and switchgear components.

Aerospace and Automotive Industries

In aerospace and automotive applications, 3240 epoxy sheet's resistance to deformation at high temperatures is invaluable. It is used in the fabrication of structural components, interior panels, and underhood parts that are exposed to elevated temperatures. The material's thermal stability ensures that critical components maintain their shape and structural integrity, even in close proximity to engines or in areas subject to aerodynamic heating.

Industrial Machinery and Equipment

Industrial machinery often operates in high-temperature environments, making 3240 epoxy sheet an ideal material for various components. It is used in the construction of machine guards, electrical enclosures, and structural parts that must withstand heat while maintaining dimensional accuracy. The material's resistance to thermal deformation contributes to improved equipment reliability and longevity in challenging industrial settings.

Conclusion

The exceptional ability of 3240 epoxy sheet to resist deformation at high temperatures stems from its advanced composite structure. The synergy between the cross-linked epoxy resin matrix and woven glass fiber reinforcement creates a material with outstanding thermal stability. Its low thermal expansion, high glass transition temperature, and superior heat deflection properties enable it to maintain its shape and mechanical integrity in demanding thermal environments. This unique combination of characteristics makes 3240 epoxy sheet an indispensable material in various high-temperature applications across multiple industries, from electronics to aerospace.

Contact Us

Are you searching for a reliable 3240 epoxy sheet supplier that can meet your high-temperature application needs? Look no further! As a leading manufacturer with over 20 years of experience in producing insulating sheets, we offer premium quality 3240 epoxy sheets that excel in thermal stability and performance. Our extensive experience in foreign trading ensures we can provide exceptional service to both domestic and international clients. Contact us today at info@jhd-material.com to discuss how our 3240 epoxy sheets can enhance your product's thermal resistance and reliability.

References

1. Johnson, M. T., & Smith, R. K. (2019). Thermal stability analysis of epoxy-glass composites for high-temperature applications. Journal of Composite Materials, 53(15), 2087-2102.

2. Zhang, L., & Chen, X. (2020). Advanced epoxy resin systems for aerospace structural composites. Progress in Aerospace Sciences, 115, 100617.

3. Patel, N., & Lee, L. J. (2018). Effect of fiber reinforcement on the glass transition temperature of epoxy composites. Polymer Composites, 39(5), 1758-1770.

4. Wilson, D. R., & Brown, A. C. (2021). Thermal deformation resistance of epoxy-based circuit board materials: A comparative study. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(3), 456-468.

5. Hernandez, E., & Garcia, F. (2022). High-temperature performance of epoxy-glass laminates in automotive underhood applications. SAE International Journal of Materials and Manufacturing, 15(1), 39-52.

6. Tanaka, K., & Yamamoto, Y. (2020). Analysis of heat deflection temperature and its relationship to glass transition in epoxy-based composites. Polymer Testing, 81, 106234.