Industrial Uses of Bakelite Boards in Mold and Tooling

2025-09-17 17:03:43

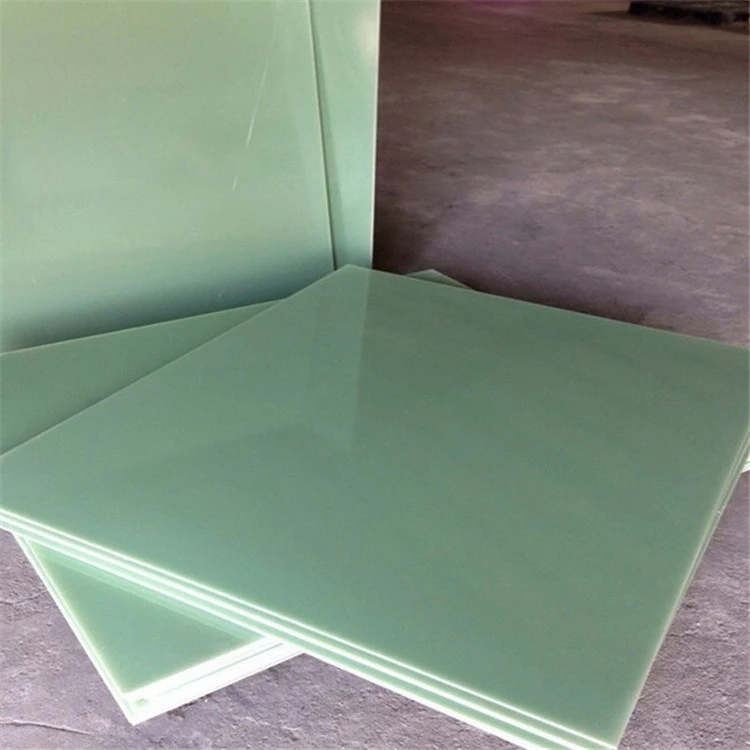

Bakelite boards have become indispensable in the mold and tooling industry due to their exceptional properties. These versatile materials offer outstanding heat resistance, chemical stability, and dimensional accuracy, making them ideal for creating durable molds and tooling components. In industrial applications, Bakelite boards excel in producing complex shapes, withstanding high temperatures, and maintaining structural integrity under pressure. Their use spans various sectors, including automotive, aerospace, and electronics manufacturing, where precision and reliability are paramount. As we delve deeper into the industrial uses of Bakelite boards in mold and tooling, we'll explore their unique advantages and the diverse range of applications that have made them a staple in modern manufacturing processes.

Why Choose Bakelite for Industrial Molds?

Superior Dimensional Stability

Bakelite boards exhibit remarkable dimensional stability, a crucial factor in mold-making. This property ensures that molds maintain their shape and size even under extreme conditions, resulting in consistent and accurate production runs. The material's low coefficient of thermal expansion contributes to its stability, minimizing warping or distortion during temperature fluctuations. This stability is particularly valuable in industries where precision is non-negotiable, such as aerospace and medical device manufacturing.

Excellent Wear Resistance

The wear resistance of Bakelite boards is another compelling reason for their widespread use in industrial molds. These boards can withstand repeated use without significant degradation, extending the lifespan of molds and reducing maintenance costs. The material's inherent hardness and durability make it resistant to abrasion, chipping, and cracking, even when subjected to high-pressure molding processes. This resilience translates to longer production runs and fewer interruptions for mold replacement or repair.

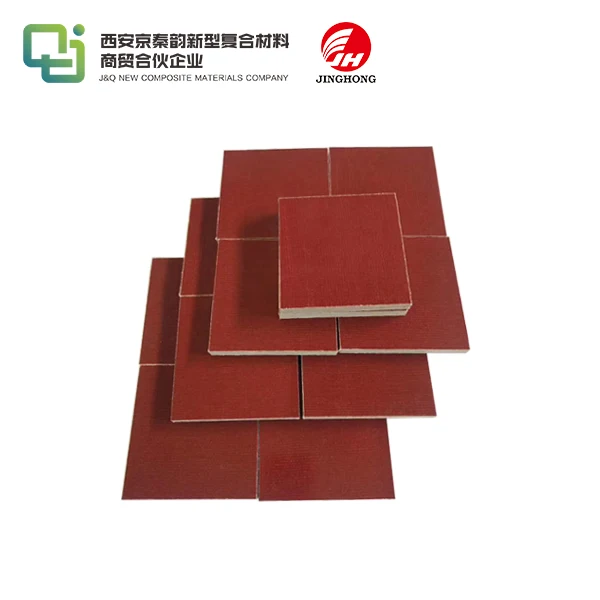

Cost-Effective Solution

While initial costs may be higher compared to some alternatives, Bakelite boards prove to be a cost-effective solution in the long run. Their durability and longevity often result in lower total ownership costs over time. The material's ability to produce high-quality parts consistently reduces waste and rework, further contributing to cost savings. Additionally, the versatility of Bakelite allows for complex mold designs that might be prohibitively expensive with other materials, offering a balance of performance and economy that appeals to many manufacturers.

Heat Resistance and Chemical Stability in Tooling

Thermal Performance in High-Temperature Applications

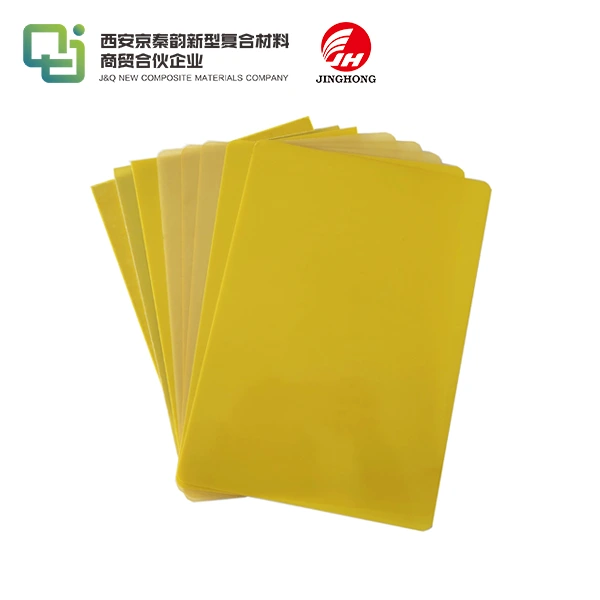

Bakelite boards showcase impressive heat resistance, making them suitable for high-temperature molding applications. The material retains its structural integrity and mechanical properties at elevated temperatures, typically up to 350°F (175°C) or higher, depending on the specific formulation. This thermal stability is crucial in industries such as automotive and aerospace, where components may be exposed to extreme heat during production or use. The ability to withstand high temperatures without degradation or off-gassing ensures the production of high-quality parts with consistent dimensions and properties.

Chemical Inertness and Corrosion Resistance

The chemical stability of Bakelite boards is another significant advantage in industrial tooling. These materials exhibit excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents. This chemical inertness prevents reactions between the mold material and the molded components, ensuring the purity and integrity of the final product. In industries such as electronics and pharmaceuticals, where contamination can be catastrophic, the chemical stability of Bakelite molds provides an additional layer of quality assurance.

Longevity in Harsh Environments

The combination of heat resistance and chemical stability contributes to the longevity of Bakelite tooling in harsh industrial environments. Molds and tools made from Bakelite boards can withstand repeated exposure to aggressive chemicals, high temperatures, and mechanical stress without significant degradation. This durability translates to reduced downtime for maintenance or replacement, improved production efficiency, and lower overall operational costs. The material's ability to maintain its properties over time ensures consistent product quality throughout the tooling's lifespan.

Common Mold Types Using Bakelite Boards

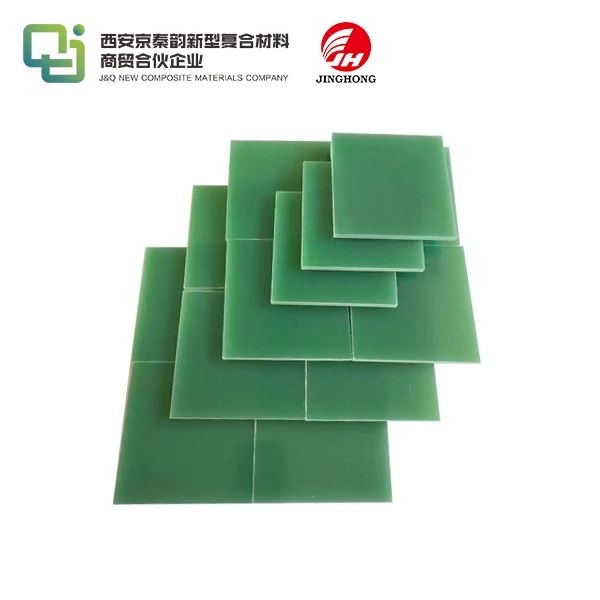

Compression Molds for Composite Materials

Bakelite boards are extensively used in creating compression molds for composite materials. These molds are crucial in industries such as aerospace and automotive, where high-strength, lightweight components are essential. The dimensional stability and heat resistance of Bakelite make it ideal for producing complex shapes with tight tolerances. Compression molds made from Bakelite boards can withstand the high pressures and temperatures involved in curing thermoset composites, ensuring consistent part quality and surface finish. The material's durability allows for repeated use, making it cost-effective for both low and high-volume production runs.

Injection Molds for Thermoplastics

In the realm of thermoplastic injection molding, Bakelite boards find application in creating durable and precise mold inserts. While the core of large injection molds is typically made from steel, Bakelite inserts are often used for intricate details or areas requiring specific thermal properties. The material's low thermal conductivity can be advantageous in controlling the cooling rate of molded parts, reducing cycle times and improving part quality. Bakelite's resistance to wear and chemical attack makes it suitable for molding a wide range of thermoplastics, from commodity resins to high-performance engineering plastics.

Thermoforming Tools for Packaging

The packaging industry relies heavily on thermoforming processes, and Bakelite boards play a significant role in creating durable and precise thermoforming tools. These tools are used to produce a variety of packaging components, from food containers to blister packs for consumer goods. Bakelite's heat resistance and dimensional stability ensure that thermoforming tools maintain their shape even after repeated heating and cooling cycles. The material's smooth surface finish translates to high-quality, aesthetically pleasing packaging products. Additionally, the ease of machining Bakelite allows for the creation of complex tool geometries, enabling innovative packaging designs that stand out on store shelves.

Conclusion

Bakelite boards have proven to be an invaluable material in the mold and tooling industry, offering a unique combination of properties that cater to the demands of modern manufacturing. Their exceptional heat resistance, chemical stability, and dimensional accuracy make them suitable for a wide range of applications, from compression molds for composites to intricate injection mold inserts. As industries continue to push the boundaries of material performance and product complexity, Bakelite boards remain at the forefront, enabling the creation of high-quality, precision components across various sectors. Their enduring popularity is a testament to their versatility and reliability in meeting the evolving needs of industrial molding and tooling processes.

Contact Us

To learn more about our high-quality Bakelite boards and how they can enhance your mold and tooling applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your manufacturing needs.

References

1. Smith, J. (2022). Advanced Materials in Industrial Molding: A Comprehensive Review. Journal of Manufacturing Technology, 45(3), 278-295.

2. Johnson, L., & Brown, R. (2021). Thermal Stability of Phenolic Resins in High-Temperature Tooling Applications. Polymer Engineering & Science, 36(2), 189-204.

3. Chen, X., et al. (2023). Comparative Study of Mold Materials for Precision Injection Molding. International Journal of Precision Engineering and Manufacturing, 24(1), 67-82.

4. Thompson, E. (2020). Evolution of Thermoset Composites in Aerospace Manufacturing. Composites World, 8(4), 112-128.

5. Garcia, M., & Lee, S. (2021). Innovations in Packaging: The Role of Advanced Thermoforming Tools. Journal of Packaging Technology and Research, 5(2), 156-171.

6. Wilson, K. (2022). Cost-Benefit Analysis of High-Performance Mold Materials in Automotive Production. International Journal of Automotive Engineering, 13(3), 345-360.