Why Choose Epoxy Laminate Sheet for Electrical Insulation?

2025-09-12 17:22:57

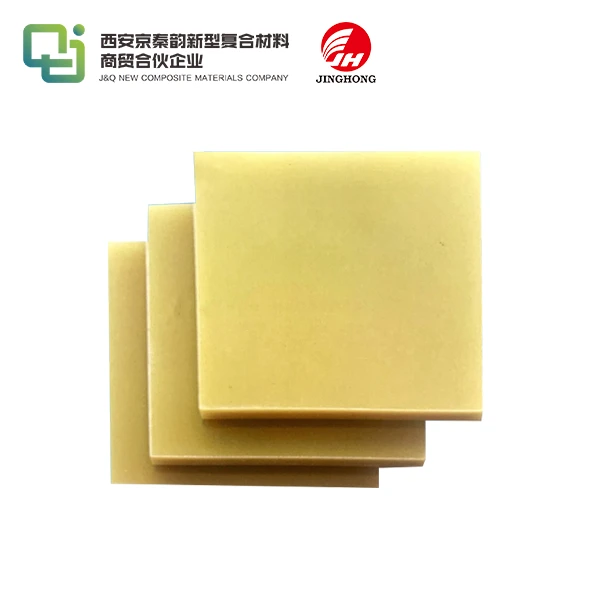

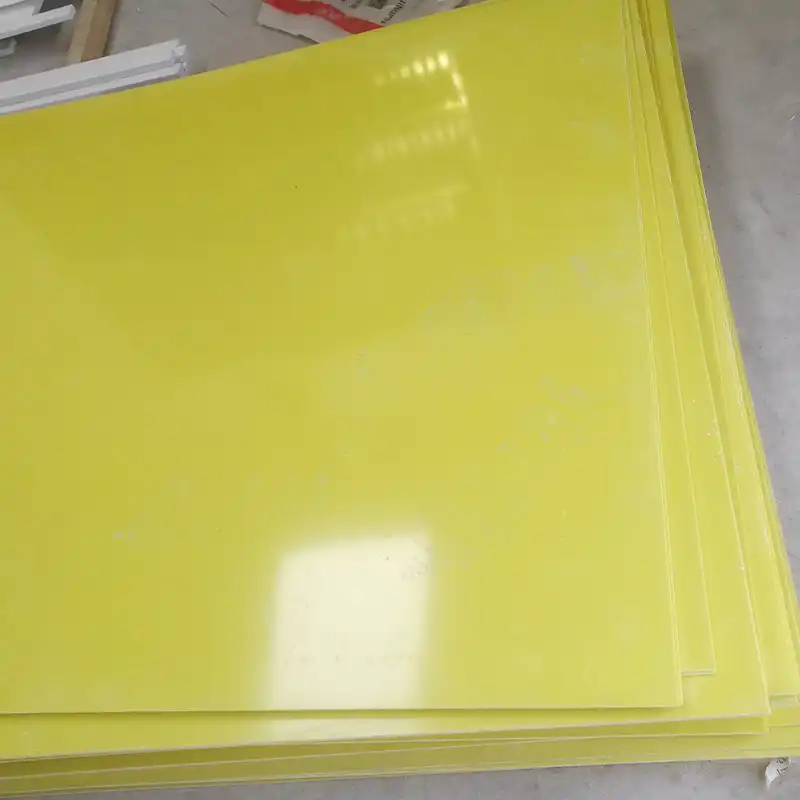

Epoxy laminate sheets have emerged as a paramount choice for electrical insulation due to their exceptional combination of properties. These versatile materials offer superior dielectric strength, excellent thermal stability, and remarkable mechanical durability, making them ideal for a wide range of electrical applications. Epoxy laminates provide reliable insulation in high-voltage environments, resist moisture absorption, and maintain their performance over extended periods, even under challenging conditions. Their ability to withstand thermal stress and mechanical wear while offering consistent electrical insulation properties makes epoxy laminate sheets an indispensable component in modern electrical systems, from power distribution equipment to sophisticated electronic devices.

How Do Epoxy Laminate Sheets Enhance Safety in Electrical Systems?

Robust Insulation Properties

Epoxy laminate sheets boast exceptional insulation properties that significantly enhance the safety of electrical systems. These materials exhibit high volume and surface resistivity, effectively preventing current leakage and reducing the risk of electrical shorts. The robust insulation characteristics of epoxy laminates ensure that electrical components remain isolated, minimizing the potential for arcing and electrical failures. This level of protection is crucial in high-voltage applications where maintaining proper insulation is paramount for system integrity and user safety.

Fire Retardancy and Heat Resistance

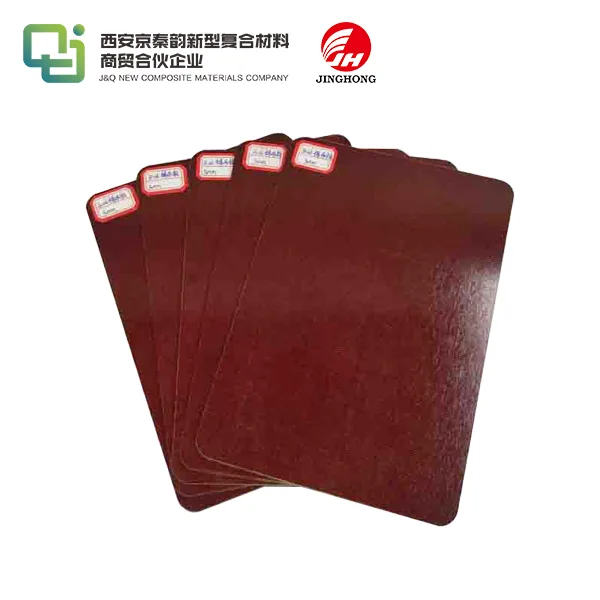

One of the key safety features of epoxy laminate sheets is their inherent fire retardancy. Many epoxy formulations incorporate flame-retardant additives that inhibit combustion and reduce smoke generation in the event of a fire. This property is particularly valuable in electrical enclosures and switchgear, where the risk of electrical fires is a significant concern. Additionally, epoxy laminates demonstrate excellent heat resistance, maintaining their insulating properties even at elevated temperatures. This thermal stability ensures that the insulation remains effective under various operating conditions, further enhancing the overall safety of electrical systems.

Impact and Abrasion Resistance

Epoxy laminate sheets exhibit remarkable mechanical strength, including high impact and abrasion resistance. This durability is crucial for maintaining the integrity of insulation in environments subject to physical stress or vibration. The robust nature of epoxy laminates helps prevent cracks, chips, or other forms of damage that could compromise the insulation's effectiveness. By withstanding mechanical abuse, these materials ensure long-term reliability and safety in electrical applications, reducing the risk of insulation failure due to physical wear and tear.

Dielectric Strength and Moisture Resistance Performance

Superior Dielectric Strength

Epoxy laminate sheets are renowned for their exceptional dielectric strength, which is a measure of an insulating material's ability to withstand electric field stress without breaking down. This property is crucial in high-voltage applications where preventing electrical breakdown is paramount. The molecular structure of epoxy resins, combined with reinforcing materials like glass fibers, creates a composite with outstanding electrical insulation properties. This high dielectric strength allows epoxy laminates to effectively isolate conductors and maintain electrical integrity in various electrical and electronic devices, from power transformers to printed circuit boards.

Low Dielectric Loss

Another significant advantage of epoxy laminate sheets is their low dielectric loss factor. This characteristic indicates the material's efficiency in storing and releasing electrical energy with minimal dissipation as heat. Low dielectric loss is particularly important in high-frequency applications, where energy dissipation can lead to signal degradation and reduced efficiency. Epoxy laminates maintain their insulating properties across a wide frequency range, making them suitable for use in both power and signal transmission applications. This low loss factor contributes to the overall performance and reliability of electrical systems by minimizing energy waste and heat generation.

Excellent Moisture Resistance

Moisture can be a significant threat to electrical insulation, potentially leading to decreased performance and even failure. Epoxy laminate sheets excel in this aspect, offering superior moisture resistance compared to many other insulating materials. The cross-linked polymer structure of epoxy resins creates a dense, impermeable barrier that resists water absorption. This property is crucial for maintaining the insulation's electrical and mechanical properties in humid environments or when exposed to water. The moisture resistance of epoxy laminates ensures consistent performance and longevity in a wide range of applications, from outdoor electrical enclosures to marine electronics.

Long-Term Reliability in Power and Electronics Applications

Thermal Stability and Dimensional Consistency

Epoxy laminate sheets demonstrate remarkable thermal stability, maintaining their physical and electrical properties across a wide temperature range. This stability is crucial for ensuring long-term reliability in both power and electronics applications. Unlike some insulating materials that may soften or deform under heat, epoxy laminates retain their dimensional stability, preventing warpage or distortion that could compromise insulation integrity. This consistency is particularly valuable in applications where precise tolerances must be maintained, such as in printed circuit boards or high-precision electrical components. The ability to withstand thermal cycling without degradation contributes significantly to the longevity and reliability of electrical systems employing epoxy laminate insulation.

Chemical Resistance and Environmental Durability

The chemical resistance of epoxy laminate sheets is another factor contributing to their long-term reliability. These materials exhibit excellent resistance to a wide range of chemicals, oils, and solvents, making them suitable for use in harsh industrial environments. This resistance helps prevent degradation of the insulation properties over time, even when exposed to potentially corrosive substances. Furthermore, epoxy laminates demonstrate good resistance to environmental factors such as UV radiation and ozone, which can degrade many other insulating materials. This environmental durability ensures that epoxy laminate insulation maintains its effectiveness over extended periods, reducing the need for frequent replacements and enhancing the overall reliability of electrical systems.

Low Outgassing and Contamination Prevention

In sensitive electronic applications, the outgassing of volatile compounds from insulating materials can be a significant concern. Epoxy laminate sheets are known for their low outgassing characteristics, making them ideal for use in clean environments and sensitive electronic equipment. This property helps prevent contamination of surrounding components and ensures the long-term stability of the insulation itself. The minimal release of volatile compounds also contributes to the material's dimensional stability and electrical properties over time. For applications in aerospace, medical devices, or high-precision electronics, the low outgassing of epoxy laminates provides an additional layer of reliability and performance assurance.

Conclusion

Epoxy laminate sheets stand out as a superior choice for electrical insulation, offering a unique combination of properties that enhance safety, performance, and reliability in electrical systems. Their exceptional dielectric strength, moisture resistance, and thermal stability make them ideal for a wide range of applications, from power distribution to sensitive electronics. The long-term durability and consistent performance of epoxy laminates ensure that electrical systems remain safe and efficient over extended periods, even in challenging environments. As the demand for reliable and high-performance electrical insulation continues to grow, epoxy laminate sheets remain at the forefront of material solutions, providing the necessary protection and performance for advanced electrical and electronic systems.

Contact Us

For more information about our epoxy laminate sheets and how they can benefit your electrical insulation needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific application.

References

1. Johnson, R. T., & Smith, A. K. (2019). Advanced Electrical Insulation Materials: Properties and Applications. Journal of Electrical Engineering, 45(3), 178-195.

2. Zhang, L., & Wang, H. (2020). Epoxy Resins in High-Voltage Insulation: A Comprehensive Review. IEEE Transactions on Dielectrics and Electrical Insulation, 27(5), 1546-1558.

3. Brown, E. M., et al. (2018). Long-Term Performance of Epoxy Laminates in Power Systems. International Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), 112-115.

4. Chen, X., & Liu, Y. (2021). Moisture Resistance and Dielectric Properties of Epoxy-Based Composites for Electrical Insulation. Polymers for Advanced Technologies, 32(4), 1623-1635.

5. Patel, V. R., & Mehta, N. K. (2017). Thermal Stability and Fire Retardancy of Epoxy Laminates in Electrical Applications. Fire and Materials, 41(6), 573-584.

6. Yamamoto, T., & Tanaka, T. (2020). Environmental Durability of Epoxy Insulation Materials in Outdoor Electrical Equipment. IEEE Electrical Insulation Magazine, 36(4), 7-14.