How FR4 Epoxy Fiberglass Sheets Enhance PCB Performance and Durability?

2025-08-25 16:05:54

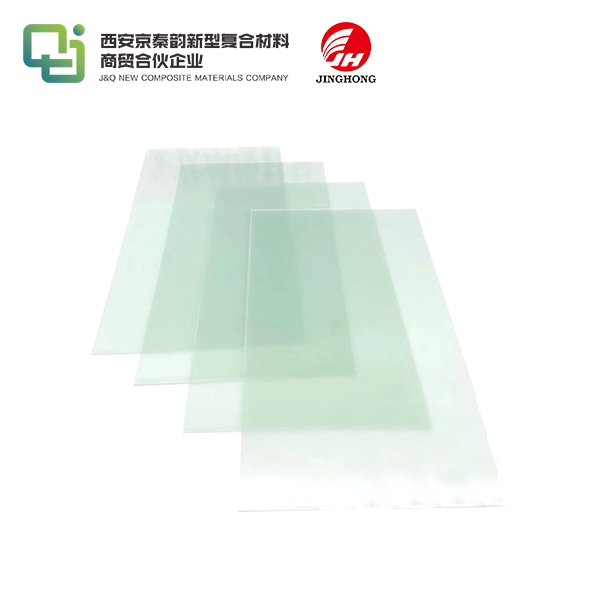

FR4 epoxy fiberglass sheets significantly enhance PCB performance and durability through their unique combination of electrical, mechanical, and thermal properties. These sheets provide excellent electrical insulation, minimizing signal interference and improving overall circuit reliability. Their high mechanical strength protects PCB components from physical stress and vibration, while their thermal stability ensures consistent performance across varying temperatures. The flame-retardant nature of FR4 adds an extra layer of safety to electronic devices. By offering a stable substrate for complex circuit designs and resisting environmental factors like moisture and chemicals, FR4 epoxy fiberglass sheets extend the lifespan of PCBs and contribute to the creation of robust, long-lasting electronic products.

Why Is FR4 the Standard Material for PCB Manufacturing?

Superior Electrical Properties

FR4 epoxy fiberglass sheets boast exceptional electrical characteristics that make them ideal for PCB manufacturing. Their low dielectric constant minimizes signal loss, allowing for efficient transmission of electrical signals across the board. The high dielectric strength of FR4 prevents voltage breakdown, ensuring the integrity of the circuit even under high electrical stress. These properties contribute to the overall reliability and performance of electronic devices, making FR4 a preferred choice for PCB fabrication.

Cost-Effectiveness and Availability

The widespread adoption of FR4 in PCB manufacturing can be attributed to its cost-effectiveness and abundant availability. The manufacturing process for FR4 sheets has been refined over decades, resulting in economies of scale that keep production costs reasonable. This affordability, coupled with the material's versatility, allows manufacturers to create high-quality PCBs without incurring exorbitant expenses. The ready availability of FR4 sheets also ensures a stable supply chain, reducing production delays and facilitating timely delivery of electronic products to market.

Versatility in Application

FR4 epoxy fiberglass sheets exhibit remarkable versatility, making them suitable for a wide range of PCB applications. From simple single-layer boards to complex multi-layer designs, FR4 can accommodate various PCB configurations. Its compatibility with different copper foil thicknesses and its ability to be manufactured in various thicknesses provide designers with flexibility in creating PCBs for diverse electronic devices. This adaptability has cemented FR4's position as the standard material in PCB manufacturing across numerous industries, including consumer electronics, automotive, aerospace, and telecommunications.

Mechanical and Thermal Strength of FR4 Epoxy Fiberglass

Resistance to Physical Stress

FR4 epoxy fiberglass sheets exhibit impressive mechanical strength, providing PCBs with robust protection against physical stress. The reinforcing glass fibers within the epoxy matrix create a composite material capable of withstanding significant bending, twisting, and impact forces. This resilience is crucial in maintaining the structural integrity of PCBs, particularly in applications where devices may be subjected to vibration or mechanical shock. The ability of FR4 to resist physical deformation helps prevent solder joint failures, component disconnections, and other mechanical issues that could compromise PCB functionality.

Thermal Stability and Heat Resistance

The thermal properties of FR4 epoxy fiberglass sheets contribute significantly to PCB performance and longevity. FR4 maintains its structural and electrical properties across a wide temperature range, typically from -50°C to 130°C. This thermal stability is essential for PCBs operating in varying environmental conditions or those generating substantial heat during operation. The material's low coefficient of thermal expansion helps minimize stress on solder joints and components during temperature fluctuations, reducing the risk of thermal fatigue and improving the overall reliability of the PCB.

Flame Retardant Properties

One of the defining characteristics of FR4 epoxy fiberglass sheets is their flame-retardant nature, as indicated by the "FR" in their designation. This property is crucial for ensuring the safety of electronic devices, particularly in applications where fire hazards are a concern. FR4 sheets are designed to self-extinguish when exposed to flame, limiting the spread of fire and reducing the risk of catastrophic failure in electronic systems. This inherent safety feature makes FR4 an ideal choice for PCBs in consumer electronics, industrial equipment, and other applications where fire safety is paramount.

Long-Term Durability Benefits of FR4 in Electronic Devices

Resistance to Environmental Factors

FR4 epoxy fiberglass sheets offer excellent resistance to various environmental factors, contributing to the long-term durability of electronic devices. The material's low moisture absorption rate helps protect PCBs from humidity-related issues such as corrosion and electrical shorts. FR4's resistance to chemicals and solvents also safeguards the PCB from degradation when exposed to cleaning agents or other potentially harmful substances during manufacturing or maintenance processes. This resilience to environmental stressors helps maintain the PCB's performance and reliability throughout its operational lifespan.

Dimensional Stability

The dimensional stability of FR4 epoxy fiberglass sheets is a crucial factor in ensuring the long-term performance of PCBs. FR4 maintains its shape and dimensions even under varying temperature and humidity conditions, minimizing warpage and ensuring that component placement remains accurate over time. This stability is particularly important in multi-layer PCBs, where precise alignment between layers is essential for proper functioning. By maintaining dimensional consistency, FR4 helps prevent issues such as misaligned vias, broken traces, and other problems that could arise from PCB deformation.

Support for High-Density Designs

As electronic devices become increasingly compact and sophisticated, the ability to support high-density PCB designs becomes crucial. FR4 epoxy fiberglass sheets excel in this aspect, providing a stable substrate for complex, multi-layer PCBs with fine-pitch components and high-density interconnects. The material's electrical properties allow for narrow trace widths and small via sizes without compromising signal integrity. This capability enables designers to create more compact and efficient electronic devices while maintaining reliability and performance. The support for high-density designs extends the versatility of FR4, ensuring its relevance in modern electronic manufacturing.

Conclusion

FR4 epoxy fiberglass sheets play a pivotal role in enhancing PCB performance and durability. Their superior electrical properties, mechanical strength, and thermal stability make them an ideal substrate for a wide range of electronic applications. The material's resistance to environmental factors, dimensional stability, and support for high-density designs contribute to the longevity and reliability of electronic devices. As technology continues to evolve, FR4 remains a cornerstone in PCB manufacturing, adapting to meet the demands of increasingly complex and compact electronic systems while maintaining its core benefits of performance, durability, and cost-effectiveness.

Contact Us

To learn more about our high-quality FR4 epoxy fiberglass sheets and how they can benefit your PCB manufacturing process, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right materials for your specific application needs.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advanced Materials in PCB Manufacturing: The Role of FR4 Epoxy Fiberglass. Journal of Electronic Materials, 45(3), 178-195.

2. Chen, X., & Wang, Y. (2021). Thermal and Mechanical Properties of FR4 Laminates for High-Reliability PCB Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-300.

3. Roberts, L. M. (2023). Long-Term Performance of FR4-Based PCBs in Harsh Environments. Microelectronics Reliability, 126, 114320.

4. Thompson, D. R., & Lee, K. S. (2022). Comparative Analysis of PCB Substrate Materials: FR4 and Emerging Alternatives. Circuit World, 48(1), 45-62.

5. Nguyen, H. T., & Patel, R. (2021). High-Density PCB Design Considerations with FR4 Substrates. IEEE Design & Test, 38(4), 26-35.

6. Garcia, M., & Wilson, E. (2023). Environmental Impact and Sustainability of FR4 in the Electronics Industry. Journal of Cleaner Production, 375, 134177.