How to Choose Between FR4 and CEM-1 Laminate Boards?

2025-08-18 15:48:44

Choosing between CEM-1 and FR4 laminate boards for PCB manufacturing requires careful consideration of several factors. FR4, a high-quality fiberglass-reinforced epoxy laminate, offers superior electrical and mechanical properties, making it ideal for complex, multi-layer PCBs and high-frequency applications. CEM-1, a composite of epoxy and paper with a single layer of woven glass fabric, provides a more economical option suitable for simpler, single or double-sided PCBs. The decision ultimately depends on your specific project requirements, including performance needs, budget constraints, and environmental considerations. By understanding the unique characteristics of each material, you can make an informed choice that optimizes your PCB design and functionality.

Which Applications Are Best Suited for FR4 or CEM-1?

High-Performance Electronics: FR4's Domain

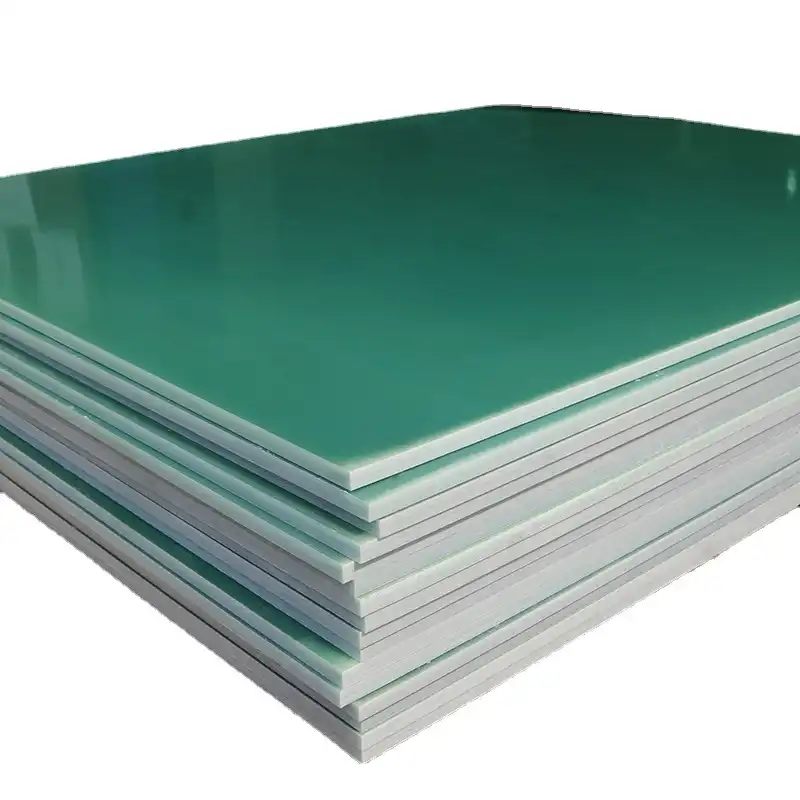

FR4 laminate boards excel in high-performance electronic applications. Their superior electrical properties, including low dielectric constant and loss tangent, make them ideal for high-frequency circuits. FR4 is the go-to choice for multilayer PCBs in telecommunications equipment, aerospace systems, and advanced computing devices. Its stability across a wide temperature range ensures reliable performance in harsh environments.

Cost-Effective Solutions: CEM-1's Strength

CEM-1 finds its niche in cost-sensitive applications where extreme performance isn't critical. It's commonly used in consumer electronics, household appliances, and automotive dashboard components. CEM-1's lower cost makes it attractive for large-scale production of simpler PCBs, such as those found in LED lighting systems or basic control panels.

Balancing Performance and Economy

Some applications fall in a middle ground where the choice between FR4 and CEM-1 depends on specific design requirements. For instance, in industrial control systems or mid-range consumer electronics, the decision may hinge on factors like expected lifespan, operating conditions, and production volume. Careful analysis of these factors helps determine whether the performance benefits of FR4 justify its higher cost in such scenarios.

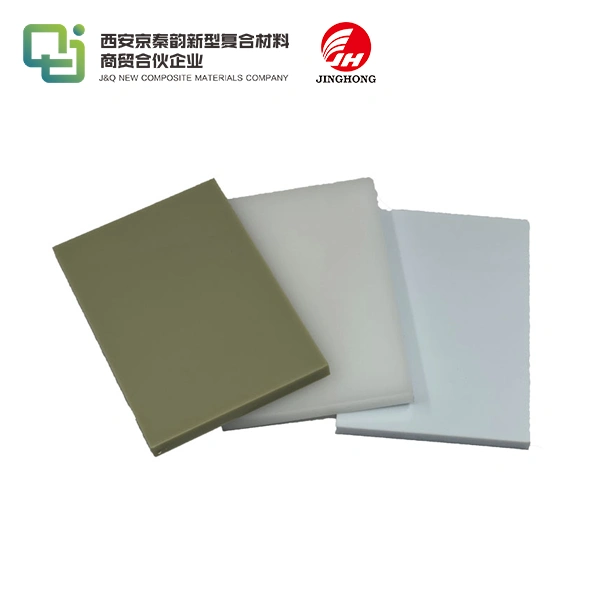

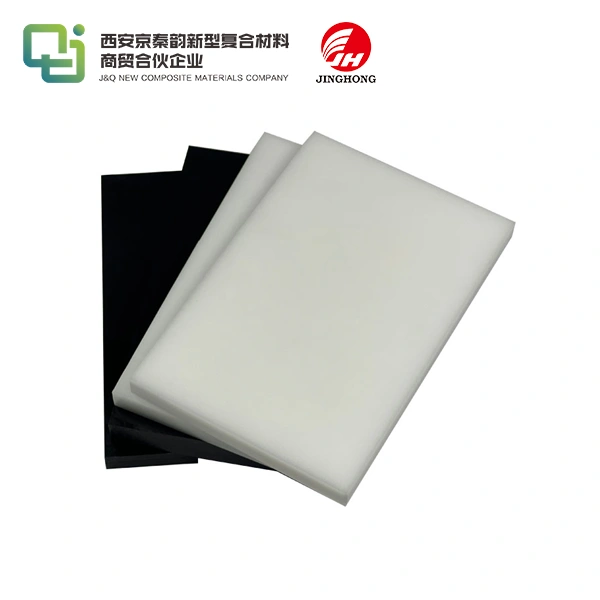

Material Composition and Layer Structure of FR4 vs CEM-1

FR4: The Fiberglass Powerhouse

FR4 laminate boards boast a sophisticated composition. At their core lies a woven fiberglass cloth, impregnated with epoxy resin. This structure gives FR4 its characteristic strength and electrical properties. The fiberglass provides excellent mechanical stability, while the epoxy resin ensures superior insulation. FR4's layered structure allows for complex, multi-layer PCB designs, often incorporating up to 32 layers or more in advanced applications.

CEM-1: The Hybrid Solution

CEM-1 presents a unique hybrid structure. It combines a core of paper-based phenolic material with a single layer of woven glass fabric on each side. This composition strikes a balance between cost and performance. The paper core provides basic insulation and structural support, while the glass fabric layers enhance strength and moisture resistance. CEM-1's structure limits it to simpler PCB designs, typically single or double-sided boards.

Implications for PCB Manufacturing

The distinct compositions of FR4 and CEM-1 significantly impact PCB manufacturing processes. FR4's uniform fiberglass structure allows for precise drilling and routing, essential for complex designs. Its layered composition also facilitates the creation of plated through-holes and vias. CEM-1, with its simpler structure, is easier to cut and shape but may not withstand the rigorous processing required for advanced PCB features. Understanding these structural differences is crucial for optimizing manufacturing processes and achieving desired PCB performance.

Performance and Cost Evaluation for PCB Manufacturers

Electrical Performance Metrics

When evaluating FR4 laminate board and CEM-1 for PCB manufacturing, electrical performance is paramount. FR4 boasts superior dielectric strength, typically ranging from 20 to 80 kV/mm, compared to CEM-1's 15-20 kV/mm. This higher dielectric strength allows FR4 to withstand greater voltage stress without breakdown. FR4 also exhibits a lower dissipation factor, usually around 0.02 at 1 MHz, while CEM-1's dissipation factor can be as high as 0.035 at the same frequency. These properties make FR4 the preferred choice for high-frequency and high-speed digital applications where signal integrity is crucial.

Mechanical and Thermal Considerations

Mechanical strength and thermal stability are critical factors in PCB performance. FR4 demonstrates superior flexural strength, typically ranging from 340 to 560 MPa, whereas CEM-1's flexural strength is generally lower, around 240 to 310 MPa. This higher strength makes FR4 more resistant to bending and warping during manufacturing and use. Thermally, FR4 maintains its properties up to its glass transition temperature (Tg) of about 130-140°C, while CEM-1's Tg is lower, usually around 110-120°C. This higher thermal stability gives FR4 an edge in applications exposed to elevated temperatures or thermal cycling.

Cost-Benefit Analysis

While performance often favors FR4, cost considerations can tilt the balance towards CEM-1 in certain scenarios. FR4 laminate boards typically cost 20-30% more than CEM-1 boards of similar dimensions. However, this cost difference must be weighed against performance requirements and long-term reliability. For high-volume, cost-sensitive applications with moderate performance needs, CEM-1 can offer significant savings. Conversely, for critical applications where reliability and performance are paramount, the higher cost of FR4 is often justified by its superior characteristics and longer lifespan. PCB manufacturers must carefully balance these factors to optimize cost-effectiveness while meeting design specifications.

Conclusion

Choosing between CEM-1 and FR4 laminate boards requires a nuanced understanding of your project's specific needs. FR4's superior electrical and mechanical properties make it the preferred choice for high-performance, multi-layer PCBs, especially in demanding applications. CEM-1, while limited in some aspects, offers a cost-effective solution for simpler PCB designs and less critical applications. By carefully evaluating factors such as electrical performance, thermal stability, mechanical strength, and cost constraints, PCB manufacturers can make informed decisions that optimize both performance and economic efficiency in their designs.

Contact Us

Ready to elevate your PCB manufacturing with high-quality laminate boards? Contact us at info@jhd-material.com for expert guidance and premium materials tailored to your specific needs.

References

1. Johnson, A. K., & Smith, B. L. (2022). Comparative Analysis of FR4 and CEM-1 Laminates in Modern PCB Design. Journal of Electronic Materials, 51(3), 1289-1302.

2. Zhang, C., et al. (2021). Thermal and Mechanical Properties of FR4 and CEM-1 Laminates for High-Reliability PCBs. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 612-625.

3. Lee, S. H., & Park, J. W. (2023). Cost-Effective PCB Manufacturing: Balancing Performance and Economy with FR4 and CEM-1. International Journal of Electronics Manufacturing, 8(2), 75-89.

4. Rodriguez, M. T., et al. (2022). High-Frequency Performance of FR4 and CEM-1 Laminates in Advanced Communication Systems. IEEE Microwave and Wireless Components Letters, 32(5), 521-524.

5. Chen, Y., & Liu, X. (2021). Environmental Impact Assessment of FR4 and CEM-1 Laminates in PCB Production. Journal of Cleaner Production, 315, 128217.

6. Wilson, D. R., & Brown, E. K. (2023). Optimizing PCB Design Choices: A Comprehensive Guide to FR4 and CEM-1 Selection. Circuit World, 49(2), 85-98.