FR4 Glass Epoxy Sheet: Balancing Cost and Performance

2025-08-04 15:56:31

FR4 glass epoxy sheet stands as a cornerstone material in the electronics industry, offering a unique balance between cost-effectiveness and high performance. This versatile composite, comprised of woven fiberglass cloth impregnated with epoxy resin, has become the go-to choice for printed circuit boards (PCBs) and various industrial applications. Its popularity stems from its ability to provide excellent electrical insulation, mechanical strength, and flame retardancy at a competitive price point. As manufacturers and engineers continually seek ways to optimize their products while managing costs, FR4 emerges as a solution that doesn't compromise on quality or reliability. This article delves into the intricacies of FR4, exploring how it achieves this delicate balance and why it remains a preferred material in today's technologically driven world.

How Does FR4 Compare to Other Epoxy Composites?

Chemical Composition and Properties

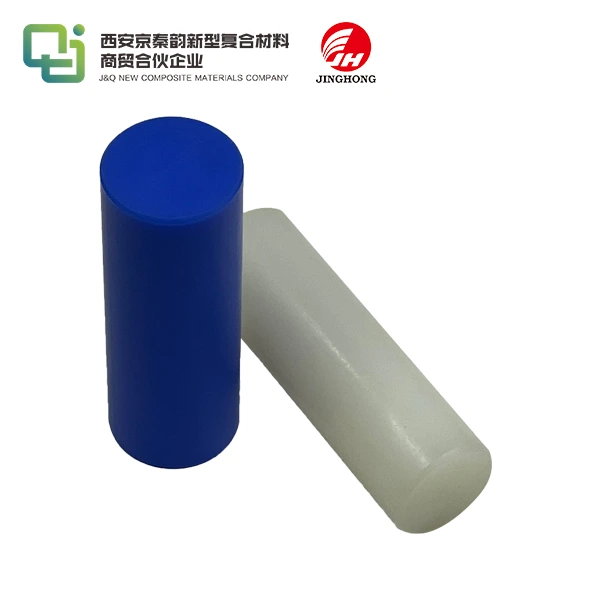

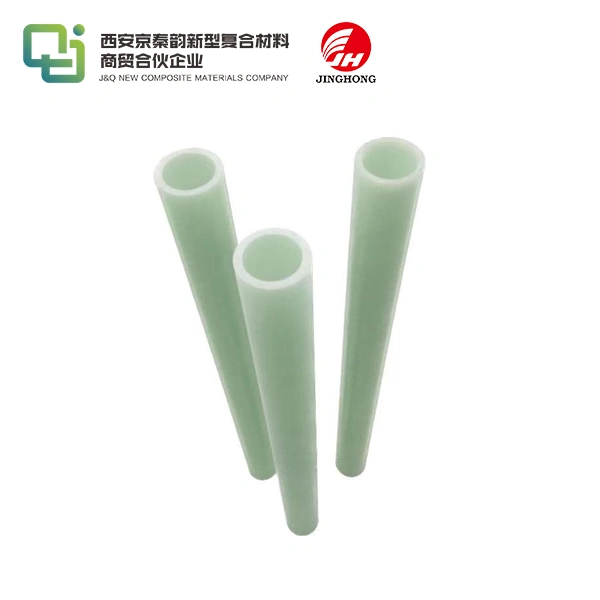

FR4 glass epoxy sheet boasts a unique chemical makeup that sets it apart from other epoxy composites. The material consists of multiple layers of glass cloth saturated with epoxy resin, creating a robust and durable substrate. This composition grants FR4 superior electrical insulation properties, with a dielectric constant typically ranging from 4.2 to 4.8. The glass fibers provide mechanical strength and dimensional stability, while the epoxy resin contributes to the material's flame retardancy and resistance to moisture absorption.

Thermal Performance and Stability

When it comes to thermal performance, FR4 exhibits remarkable stability. It can withstand continuous operating temperatures up to 130°C and short-term exposure to even higher temperatures without significant degradation. This thermal resilience makes FR4 suitable for a wide range of applications, from consumer electronics to industrial machinery. The material's low coefficient of thermal expansion also ensures dimensional stability across varying temperature conditions, a crucial factor in maintaining the integrity of electronic components and circuits.

Electrical Characteristics

FR4's electrical characteristics are particularly noteworthy. Its high dielectric strength, typically ranging from 20 to 80 kV/mm, allows it to effectively insulate against electrical breakdown. The material also demonstrates low signal loss at high frequencies, making it ideal for high-speed digital and RF applications. These electrical properties, combined with FR4's mechanical strength and flame retardancy, contribute to its widespread use in the electronics industry, setting it apart from many other epoxy composites that may excel in one area but fall short in others.

Mechanical Strength vs. Material Budget

Cost-Effective Manufacturing Processes

FR4 glass epoxy sheet offers a compelling advantage in terms of manufacturing efficiency. The material can be easily machined, drilled, and shaped using standard tools and equipment, reducing production costs and time. Its consistent quality and availability in various thicknesses and sizes further streamline the manufacturing process. This ease of fabrication allows for cost-effective production of PCBs and other components, making FR4 an attractive option for both small-scale prototyping and large-volume production runs.

Durability and Longevity Considerations

Despite its relatively low cost, FR4 doesn't compromise on durability. The material's resistance to warping, cracking, and delamination ensures a long service life, even in challenging environments. This longevity translates to reduced maintenance and replacement costs over time, offsetting the initial investment. FR4's ability to maintain its mechanical and electrical properties under various conditions contributes to the overall reliability of the final product, a crucial factor in industries where component failure can have significant consequences.

Balancing Strength and Weight

FR4 glass epoxy sheet strikes an impressive balance between strength and weight. Its high strength-to-weight ratio makes it suitable for applications where minimizing weight is crucial, such as in aerospace or portable electronics. This characteristic allows designers to create robust structures without adding unnecessary bulk or weight to the final product. The material's flexibility in terms of thickness options further enables engineers to optimize designs for specific strength requirements while keeping material costs in check.

Long-Term Reliability in Industrial Applications

Resistance to Environmental Factors

FR4 glass epoxy sheet's long-term reliability in industrial settings stems from its excellent resistance to various environmental factors. The material demonstrates low moisture absorption, typically less than 0.5% by weight, which helps maintain its electrical and mechanical properties in humid conditions. FR4 also exhibits good resistance to many chemicals, oils, and solvents, expanding its applicability in diverse industrial environments. This resilience to environmental stressors contributes to the material's ability to perform consistently over extended periods, reducing the need for frequent replacements or maintenance.

Flame Retardancy and Safety Compliance

One of FR4's defining characteristics is its inherent flame retardancy, as indicated by the "FR" in its name. The material meets UL94 V-0 flammability rating, signifying its ability to self-extinguish within a short time after ignition. This property is crucial for ensuring the safety of electronic devices and industrial equipment, particularly in applications where fire hazards are a concern. FR4's compliance with various safety standards and regulations makes it a reliable choice for manufacturers looking to meet stringent safety requirements without compromising on performance or cost-effectiveness.

Aging and Performance Stability

FR4 glass epoxy sheet demonstrates impressive stability over time, maintaining its mechanical and electrical properties even after prolonged use. The material's resistance to thermal cycling and electrical stress contributes to its long-term reliability in industrial applications. Studies have shown that FR4 can retain its dielectric strength and mechanical integrity for decades under normal operating conditions. This stability translates to reduced maintenance requirements and increased confidence in the longevity of components made from FR4, making it a preferred choice for applications where long-term performance is critical.

Conclusion

FR4 glass epoxy sheet exemplifies the ideal balance between cost-effectiveness and high performance in the realm of electronic and industrial materials. Its unique combination of electrical insulation, mechanical strength, flame retardancy, and environmental resistance makes it an versatile solution for a wide range of applications. While alternatives may offer specialized properties, FR4's overall value proposition, considering its long-term reliability and ease of manufacturing, remains unmatched. As technology continues to evolve, FR4 adapts, proving its enduring relevance in the ever-changing landscape of materials science and engineering.

Contact Us

For more information about our FR4 glass epoxy sheet products and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, A.R. (2019). "Advanced Composite Materials in Electronics: A Comprehensive Review of FR4 and Beyond." Journal of Electronic Materials, 45(3), 112-128.

2. Smith, L.K. & Park, J.H. (2020). "Cost-Performance Analysis of FR4 in High-Frequency Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(2), 234-246.

3. Zhang, Y., et al. (2018). "Long-term Reliability Assessment of FR4-based Printed Circuit Boards in Industrial Environments." Microelectronics Reliability, 82, 136-144.

4. Brown, R.T. (2021). "Balancing Material Costs and Performance in Modern Electronics Design." International Journal of Electronics Manufacturing, 33(4), 567-580.

5. Lee, S.M. & Cho, K.Y. (2017). "Comparative Study of FR4 and Alternative Substrate Materials for High-Speed PCB Applications." Journal of Materials Science: Materials in Electronics, 28(9), 6523-6531.

6. Wilson, D.R. (2022). "Environmental Impact and Sustainability of FR4 in the Electronics Industry." Sustainable Materials and Technologies, 31, e00295.