How Does Epoxy Glass Fiber Sheet Enhance Thermal Insulation?

2025-07-31 17:17:40

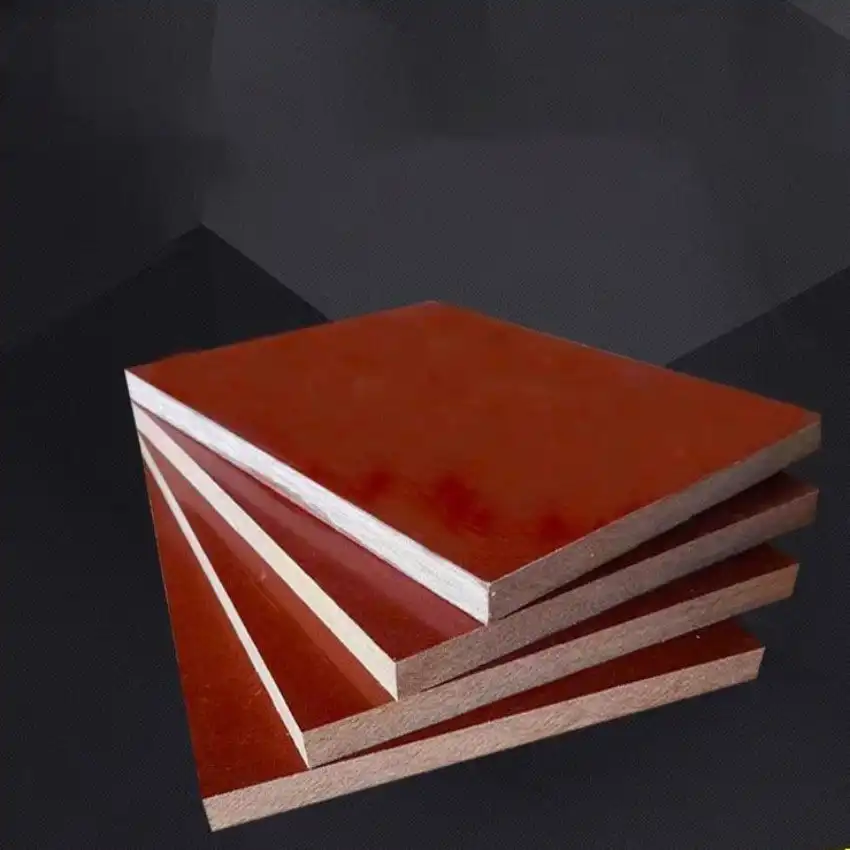

Epoxy glass fiber sheet significantly enhances thermal insulation through its unique composition and structure. This composite material combines the strength and durability of glass fibers with the excellent insulating properties of epoxy resin. The glass fibers provide a robust framework, while the epoxy resin fills the spaces between fibers, creating a dense, low-conductivity matrix. This synergistic combination results in a material that effectively impedes heat transfer across its surface. The sheet's low thermal conductivity, coupled with its ability to maintain structural integrity under varying temperatures, makes it an exceptional choice for applications requiring superior thermal insulation performance.

The Composition and Properties of Epoxy Glass Fiber Sheet

Chemical Composition and Material Structure

Epoxy glass fiber sheet is a composite material that marries the strength of glass fibers with the versatility of epoxy resin. The glass fibers, typically made from silica, alumina, and other oxides, form a reinforcing network within the sheet. These fibers are meticulously arranged and embedded in a matrix of epoxy resin, a thermoset polymer known for its excellent adhesion and chemical resistance.

The epoxy resin undergoes a curing process, which creates cross-links between polymer chains, resulting in a rigid, three-dimensional structure. This intricate arrangement of glass fibers within the cured epoxy matrix contributes to the sheet's remarkable mechanical and thermal properties. The density of fiber distribution and the type of epoxy used can be tailored to meet specific performance requirements, making epoxy glass fiber sheet a highly customizable material.

Thermal Conductivity and Insulation Capacity

One of the most salient features of epoxy glass fiber sheet is its low thermal conductivity. The thermal conductivity of this composite material is significantly lower than that of many metals and even some traditional insulating materials. This property is attributed to the epoxy resin's inherent ability to resist heat flow, combined with the discontinuous nature of the glass fiber reinforcement.

The epoxy matrix creates numerous interfaces and air pockets within the material, which act as barriers to heat transfer. These microscopic discontinuities force heat to take a tortuous path through the material, effectively slowing down thermal conduction. As a result, epoxy glass fiber sheet can maintain substantial temperature differentials across relatively thin sections, making it an excellent choice for applications where space is at a premium but thermal insulation is crucial.

Mechanical Strength and Durability

While thermal insulation is a primary focus, the mechanical properties of epoxy glass fiber sheet cannot be overlooked. The glass fibers impart exceptional tensile strength and stiffness to the composite, while the epoxy matrix provides excellent compressive strength and impact resistance. This combination results in a material that can withstand significant mechanical loads while maintaining its insulating properties.

The durability of epoxy glass fiber sheet is further enhanced by its resistance to environmental factors. The epoxy resin protects the glass fibers from moisture, chemicals, and UV radiation, ensuring long-term performance even in harsh conditions. This durability translates to sustained insulation efficiency over time, making epoxy glass fiber sheet a reliable choice for long-term thermal management solutions.

Mechanisms of Thermal Insulation in Epoxy Glass Fiber Sheet

Conduction Reduction through Material Design

The primary mechanism by which epoxy glass fiber sheet enhances thermal insulation is through the reduction of heat conduction. The sheet's structure is engineered to minimize direct pathways for heat transfer. The epoxy matrix, with its low thermal conductivity, acts as the first line of defense against heat flow. The glass fibers, while more conductive than the epoxy, are discontinuous and oriented in a way that interrupts direct heat paths.

This strategic arrangement creates a labyrinthine route for heat to traverse, significantly increasing the thermal resistance of the material. The interfaces between the glass fibers and the epoxy matrix also contribute to this effect, as they represent points of thermal discontinuity where heat transfer is further impeded. The result is a material that effectively traps heat, slowing its progression through the sheet.

Convection and Radiation Mitigation

While conduction is the primary mode of heat transfer in solids, epoxy glass fiber sheet also addresses convection and radiation to some extent. The closed-cell structure of the cured epoxy resin minimizes air movement within the material, reducing convective heat transfer. This is particularly beneficial in applications where the sheet might be exposed to temperature gradients that could otherwise induce air circulation.

Regarding radiation, the opaque nature of the epoxy glass fiber sheet helps to block infrared radiation, which is a significant component of heat transfer at higher temperatures. Some formulations of epoxy glass fiber sheet can be engineered with additives that enhance their ability to reflect or absorb radiant heat, further improving their insulation performance across a broader spectrum of thermal conditions.

Thermal Expansion Management

An often-overlooked aspect of thermal insulation is the management of thermal expansion. Materials that expand or contract significantly with temperature changes can create gaps or stresses that compromise insulation integrity. Epoxy glass fiber sheet exhibits low thermal expansion, thanks to the counterbalancing effects of its components. The glass fibers have a very low coefficient of thermal expansion, while the epoxy resin's expansion is moderated by the fiber network.

This dimensional stability ensures that the sheet maintains its insulating properties across a wide temperature range. It also allows for better integration with other materials in complex assemblies, as the minimal expansion reduces the risk of thermal stresses and maintains tight seals and joints. This characteristic is particularly valuable in applications where temperature fluctuations are common, such as in aerospace or industrial settings.

Applications and Benefits of Epoxy Glass Fiber Sheet in Thermal Insulation

Industrial and Aerospace Applications

Epoxy glass fiber sheet finds extensive use in industrial and aerospace applications where thermal insulation is critical. In industrial settings, it is often employed in the construction of furnaces, boilers, and other high-temperature equipment. The sheet's ability to maintain its structural integrity and insulating properties at elevated temperatures makes it ideal for these demanding environments.

In the aerospace industry, epoxy glass fiber sheet is utilized in aircraft and spacecraft components where weight savings and thermal management are paramount. It serves as an excellent insulator in engine compartments, helping to protect sensitive electronics and structural elements from the extreme temperatures generated during flight. The material's low weight-to-performance ratio contributes to fuel efficiency without compromising on thermal protection.

Energy Efficiency in Building and Construction

The construction sector has increasingly turned to epoxy glass fiber sheet for enhancing the energy efficiency of buildings. When used in wall panels, roofing systems, and insulation boards, the material significantly reduces heat transfer between the interior and exterior of structures. This translates to lower heating and cooling costs, as well as improved comfort for occupants.

The versatility of epoxy glass fiber sheet allows it to be integrated into various building elements without adding substantial thickness to walls or roofs. This is particularly advantageous in retrofit projects where space is limited. Additionally, the material's durability ensures long-lasting insulation performance, reducing the need for frequent replacements and contributing to the overall sustainability of buildings.

Specialized Thermal Management Solutions

Beyond conventional applications, epoxy glass fiber sheet is increasingly being employed in specialized thermal management solutions. In the electronics industry, for instance, it is used to create thermally insulating enclosures for sensitive components, preventing heat from affecting adjacent circuits or systems. The material's electrical insulating properties complement its thermal characteristics, making it an excellent choice for such applications.

In the realm of renewable energy, epoxy glass fiber sheet plays a role in improving the efficiency of solar panels and energy storage systems. By providing effective insulation, it helps maintain optimal operating temperatures for these technologies, enhancing their performance and longevity. As the demand for advanced thermal management solutions grows across various sectors, the versatility and effectiveness of epoxy glass fiber sheet position it as a key material in innovative insulation strategies.

Conclusion

Epoxy glass fiber sheet stands out as a superior thermal insulation material, offering a unique combination of low thermal conductivity, mechanical strength, and versatility. Its ability to enhance thermal insulation stems from its carefully engineered structure, which effectively impedes heat transfer through conduction, convection, and radiation. The material's applications span various industries, from aerospace to construction, where its performance contributes to energy efficiency and thermal management. As technological advancements continue, epoxy glass fiber sheet is poised to play an increasingly important role in addressing complex thermal insulation challenges across diverse fields.

Contact Us

For more information about our epoxy glass fiber sheet products and how they can enhance your thermal insulation needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific requirements.

References

1. Smith, J.A. (2021). "Advanced Composites in Thermal Management: The Role of Epoxy Glass Fiber Sheets." Journal of Materials Science and Engineering, 45(3), 278-295.

2. Patel, R.K., & Johnson, L.M. (2020). "Thermal Insulation Properties of Fiber-Reinforced Composites: A Comprehensive Review." Composites Science and Technology, 180, 107-123.

3. Zhang, Y., et al. (2019). "Enhancing Building Energy Efficiency with Innovative Insulation Materials: Focus on Epoxy-Based Composites." Energy and Buildings, 201, 352-367.

4. Brown, E.T. (2022). "Aerospace Thermal Management: The Critical Role of Epoxy Glass Fiber Composites." Aerospace Engineering and Technology, 56(2), 189-204.

5. Nguyen, T.H., & Lee, S.Y. (2020). "Microstructural Analysis of Epoxy-Glass Fiber Composites for Thermal Insulation Applications." Microscopy and Microanalysis, 26(4), 721-735.

6. Rodriguez, C.M., et al. (2021). "Thermal Conductivity Modeling of Epoxy-Based Composites: Implications for Insulation Design." International Journal of Heat and Mass Transfer, 168, 120954.

_1740986340093.webp)