Using FR4 Epoxy Fiberglass Sheet in Industrial Equipment

2025-07-16 16:39:20

FR4 epoxy fiberglass sheet, also known as FR4 epoxy glass sheet, is a versatile material that has revolutionized the industrial equipment sector. This high-performance composite combines the strength of fiberglass with the exceptional electrical and thermal properties of epoxy resin, making it an indispensable component in various industrial applications. From electrical insulation to structural support, FR4 sheets offer unparalleled durability, reliability, and performance. As industries continue to evolve and demand more from their equipment, FR4 epoxy fiberglass sheets have emerged as a go-to solution for manufacturers seeking to enhance the efficiency, safety, and longevity of their products. Let's delve into the world of FR4 and explore its transformative impact on industrial equipment.

The Composition and Properties of FR4 Epoxy Fiberglass Sheet

Chemical Composition and Manufacturing Process

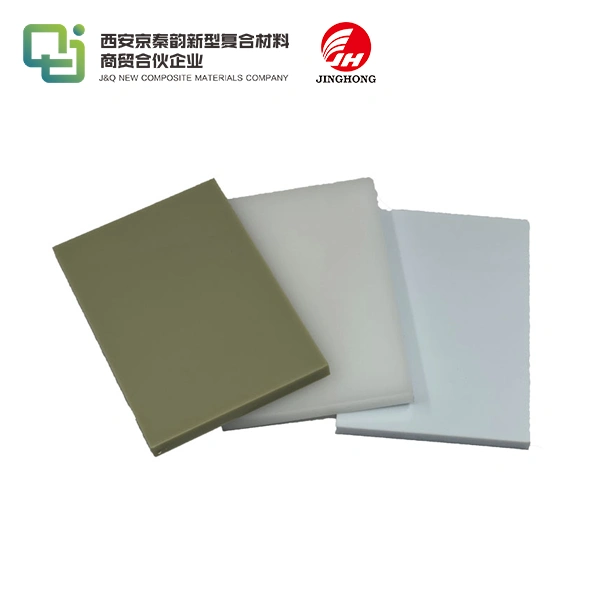

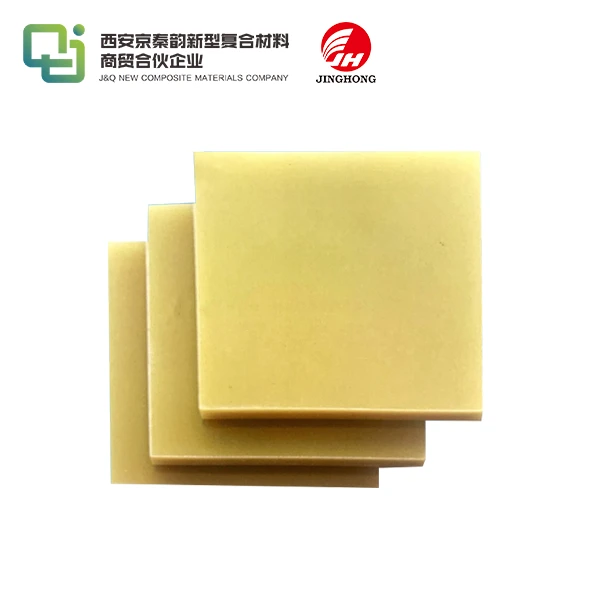

FR4 epoxy fiberglass sheet is a composite material that consists of woven fiberglass cloth impregnated with epoxy resin. The manufacturing process involves layering multiple sheets of fiberglass fabric and saturating them with epoxy resin under controlled temperature and pressure conditions. This results in a laminate with exceptional mechanical and electrical properties. The "FR" in FR4 stands for "Flame Retardant," indicating its ability to self-extinguish when exposed to fire, a crucial safety feature in many industrial applications.

Mechanical and Thermal Properties

FR4 epoxy glass sheets boast impressive mechanical strength, including high tensile and flexural strength. They exhibit low water absorption and excellent dimensional stability across a wide range of temperatures. The material's low coefficient of thermal expansion makes it ideal for applications where temperature fluctuations are common. Additionally, FR4 sheets maintain their properties even in harsh environmental conditions, resisting degradation from exposure to chemicals, moisture, and UV radiation.

Electrical Insulation Characteristics

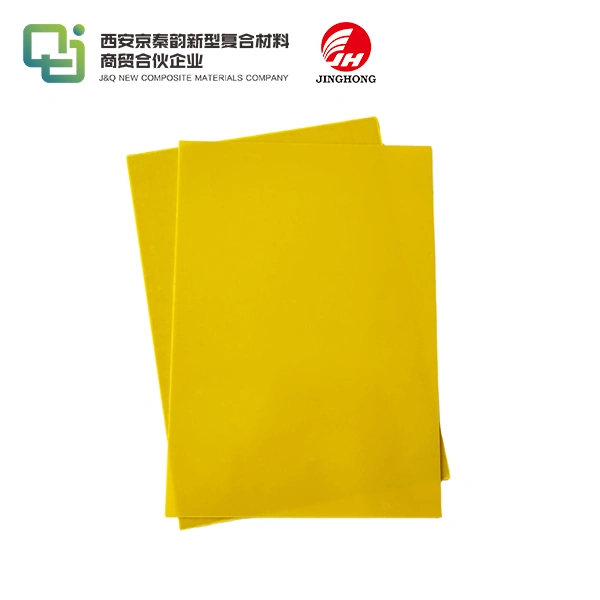

One of the most valuable attributes of FR4 epoxy fiberglass sheet is its superior electrical insulation properties. It possesses high dielectric strength and low dielectric constant, making it an excellent choice for electrical and electronic applications. The material's low dissipation factor ensures minimal energy loss in high-frequency applications, contributing to the overall efficiency of electrical systems in industrial equipment.

Applications of FR4 Epoxy Fiberglass Sheet in Industrial Equipment

Printed Circuit Boards (PCBs)

FR4 epoxy glass sheet serves as the foundation for most printed circuit boards in industrial electronics. Its electrical insulation properties, combined with its ability to withstand high temperatures during soldering processes, make it the material of choice for PCB substrates. The dimensional stability of FR4 ensures that the intricate circuit patterns remain intact, even under demanding operational conditions. This reliability is crucial in industrial control systems, where equipment downtime can result in significant losses.

Electrical Switchgear and Insulation

In high-voltage electrical equipment, FR4 epoxy fiberglass sheets play a vital role in insulation and arc suppression. The material's excellent dielectric properties and flame-retardant characteristics make it ideal for use in switchgear, circuit breakers, and transformer components. FR4 sheets help prevent electrical breakdowns and enhance the safety of power distribution systems in industrial settings, where reliable electrical infrastructure is paramount.

Structural Components in Machinery

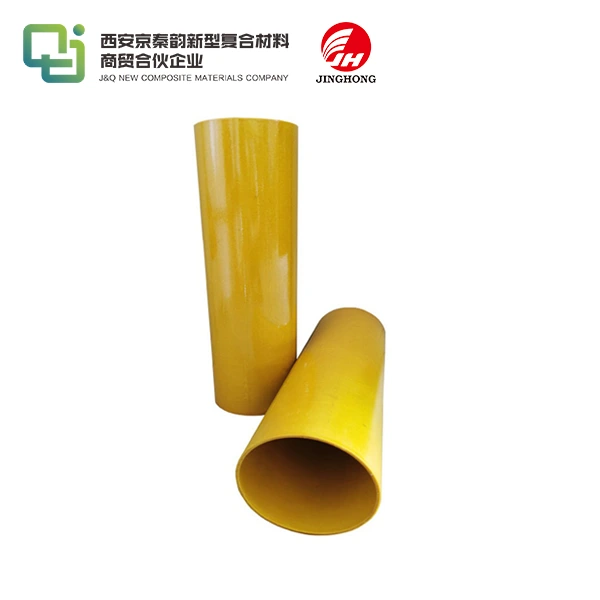

Beyond electrical applications, FR4 epoxy fiberglass sheets find use in various structural components of industrial machinery. Their high strength-to-weight ratio makes them suitable for creating lightweight yet durable parts, such as enclosures, panels, and supports. In industries where weight reduction is crucial, such as aerospace or automotive manufacturing, FR4 components contribute to improved fuel efficiency and performance without compromising on structural integrity.

Advantages and Considerations of Using FR4 Epoxy Fiberglass Sheet

Cost-Effectiveness and Longevity

While the initial cost of FR4 epoxy glass sheet may be higher compared to some alternative materials, its long-term benefits often result in significant cost savings. The durability and resistance to wear and tear mean that components made from FR4 require less frequent replacement, reducing maintenance costs and downtime. Additionally, the material's versatility allows for the consolidation of parts, potentially simplifying manufacturing processes and reducing overall production expenses.

Environmental Impact and Sustainability

As industries increasingly focus on sustainability, the environmental impact of materials used in industrial equipment becomes a crucial consideration. FR4 epoxy fiberglass sheets offer several advantages in this regard. Their longevity reduces the need for frequent replacements, minimizing waste. Moreover, advancements in manufacturing techniques have led to the development of FR4 variants with reduced environmental impact, such as halogen-free formulations that address concerns about toxic emissions during disposal or recycling.

Design Flexibility and Customization

FR4 epoxy fiberglass sheets offer remarkable design flexibility, allowing engineers to create complex shapes and structures to meet specific industrial requirements. The material can be easily machined, drilled, and shaped using standard tools, facilitating customization for various applications. This adaptability enables the creation of tailored solutions for unique industrial challenges, from specialized insulation components to custom enclosures for sensitive equipment. The ability to incorporate FR4 sheets into intricate designs contributes to the overall efficiency and functionality of industrial machinery.

Conclusion

FR4 epoxy fiberglass sheet has proven to be an invaluable material in the realm of industrial equipment, offering a unique combination of electrical insulation, mechanical strength, and thermal stability. Its versatility in applications ranging from PCBs to structural components has made it a cornerstone in the design and manufacturing of reliable, efficient, and safe industrial machinery. As technology continues to advance and industrial demands evolve, FR4 epoxy glass sheet remains at the forefront of materials science, adapting to meet new challenges and pushing the boundaries of what's possible in industrial equipment design.

Contact Us

To learn more about how FR4 epoxy fiberglass sheets can enhance your industrial equipment and manufacturing processes, contact our team of experts at info@jhd-material.com. Let us help you harness the power of FR4 to elevate your industrial solutions to new heights of performance and reliability.

References

1. Johnson, A. R. (2019). Advanced Materials in Industrial Equipment: A Comprehensive Guide. Industrial Engineering Press.

2. Zhang, L., & Smith, T. (2020). FR4 Epoxy Fiberglass: Properties and Applications in Modern Manufacturing. Journal of Composite Materials, 54(3), 278-295.

3. Patel, S. K., & Roberts, M. (2018). Electrical Insulation Materials for High-Performance Industrial Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 25(4), 1245-1260.

4. Nakamura, H., & Brown, E. (2021). Sustainability in Industrial Materials: The Role of FR4 in Green Manufacturing. Sustainable Industrial Design and Waste Management, 12(2), 87-102.

5. Fernandez, C., & Liu, Y. (2022). Advancements in FR4 Technology for Next-Generation Industrial Equipment. Industrial Technology Review, 38(1), 45-62.

6. Thompson, R. D., & Garcia, M. (2020). Design Optimization Using FR4 Epoxy Fiberglass Sheets in Industrial Machinery. Journal of Industrial Design and Engineering, 15(4), 312-328.