How to Order Custom Cut Epoxy Laminate Sheets Easily?

2025-06-30 15:44:56

Ordering custom cut epoxy laminate sheets has never been simpler. To get started, reach out to a reputable manufacturer with your specific requirements, including dimensions, thickness, and any special properties needed. Provide detailed drawings or specifications if available. The manufacturer will guide you through material options, discuss feasibility, and offer a quote. Once you approve the quote, they'll begin production, ensuring quality control throughout. Many manufacturers offer online ordering systems or dedicated customer service teams to streamline the process. With clear communication and the right supplier, you can effortlessly obtain precisely cut epoxy laminate sheets tailored to your project needs.

Understanding Epoxy Laminate Sheets and Their Applications

Composition and Properties of Epoxy Laminate Sheets

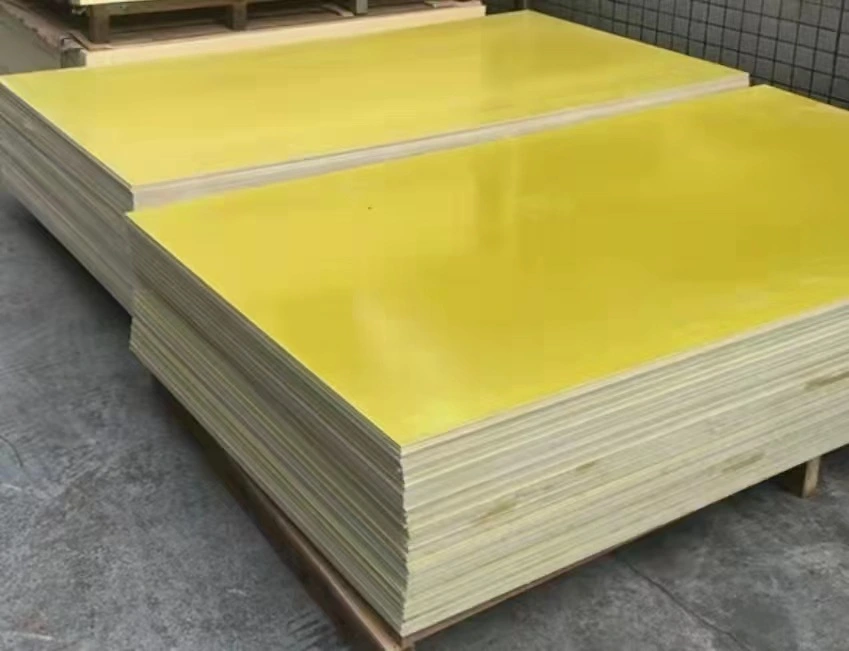

Epoxy laminate sheets are composite materials consisting of epoxy resin reinforced with various fibers or fabrics. These sheets boast exceptional mechanical strength, electrical insulation, and chemical resistance. The epoxy matrix provides durability and adhesion, while the reinforcement enhances structural integrity. Depending on the specific formulation, these laminates can offer properties such as flame retardancy, low moisture absorption, and dimensional stability across a wide temperature range.

Common Applications in Industry and Electronics

The versatility of epoxy laminate sheets makes them indispensable in numerous industries. In electronics, they serve as circuit board substrates, offering excellent dielectric properties and thermal management. Aerospace and automotive sectors utilize these materials for lightweight yet strong structural components. Marine applications benefit from their corrosion resistance and durability in harsh environments. Additionally, epoxy laminates find use in industrial machinery, consumer goods, and even artistic creations, showcasing their adaptability across diverse fields.

Advantages of Custom Cut Epoxy Laminate Sheets

Opting for custom cut epoxy laminate sheets offers several advantages. Precision cutting ensures exact fit for specific applications, reducing waste and improving efficiency. Custom cuts allow for complex shapes and sizes that may not be available in standard offerings. This tailored approach can lead to cost savings in the long run by eliminating the need for on-site modifications. Moreover, custom cutting can incorporate features like holes, slots, or beveled edges, streamlining assembly processes and enhancing the final product's functionality.

Preparing to Order Custom Cut Epoxy Laminate Sheets

Determining Your Specific Requirements

Before placing an order for custom cut epoxy laminate sheets, it's crucial to define your project's exact needs. Consider the intended application, environment, and performance expectations. Determine the required dimensions, thickness, and tolerances. Evaluate any special properties needed, such as specific dielectric strength, flame resistance, or thermal conductivity. If the laminate will be exposed to chemicals or extreme temperatures, factor these conditions into your specifications. Creating a comprehensive list of requirements ensures you'll receive a product that perfectly suits your application.

Choosing the Right Type of Epoxy Laminate

Epoxy laminates come in various grades and compositions, each optimized for different applications. FR-4 is a popular choice for electrical and electronic applications due to its flame-retardant properties and excellent insulation. G10 and G11 grades offer high mechanical strength and are often used in structural components. For high-temperature applications, polyimide-based laminates might be more suitable. Consider the reinforcement material as well; glass fiber provides good strength and insulation, while carbon fiber offers superior stiffness and conductivity. Consulting with a knowledgeable supplier can help you select the ideal laminate for your specific needs.

Gathering Necessary Information for the Order

To ensure a smooth ordering process, compile all relevant information beforehand. This includes detailed dimensions, quantity required, and any special cutting or machining instructions. If you have technical drawings or CAD files, prepare these for submission. Note any critical tolerances or surface finish requirements. If your project involves multiple pieces or a complex assembly, provide assembly diagrams or exploded views to help the manufacturer understand the context. Additionally, specify any packaging or delivery requirements, especially if the cut sheets need special handling or protection during shipping.

Navigating the Ordering Process

Finding a Reliable Epoxy Laminate Sheet Supplier

Locating a trustworthy supplier is paramount when ordering custom cut epoxy laminate sheets. Look for manufacturers with extensive experience in the field and a proven track record of quality production. Check for certifications such as ISO 9001, which indicate adherence to quality management standards. Read customer reviews and testimonials to gauge satisfaction levels. Consider the supplier's technical expertise and their ability to provide guidance on material selection and custom cutting options. A reliable supplier should offer clear communication channels and be responsive to inquiries throughout the ordering process.

Requesting and Evaluating Quotes

Once you've identified potential suppliers, submit your specifications for quotes. Provide as much detail as possible to ensure accurate pricing. When evaluating quotes, look beyond just the price. Consider factors such as lead time, quality guarantees, and the supplier's capability to meet your specific requirements. Some suppliers may offer value-added services like prototyping or design assistance, which could be beneficial for complex projects. Don't hesitate to ask for clarification on any aspects of the quote, including material grades, cutting tolerances, or finishing options. A thorough evaluation at this stage can prevent misunderstandings and ensure you receive the best value for your investment.

Finalizing Your Order and Production Timeline

After selecting a supplier and agreeing on the quote, it's time to finalize your order. Review all specifications one last time to ensure accuracy. Discuss and agree upon a production timeline that aligns with your project schedule. Many suppliers offer expedited services for urgent needs, but these may come at a premium. Clarify any quality control measures and testing procedures that will be employed during production. Establish clear expectations for communication during the manufacturing process, including any milestones or approval stages. Finally, confirm the delivery method and any special handling instructions to ensure your custom cut epoxy laminate sheets arrive in perfect condition.

Conclusion

Ordering custom cut epoxy laminate sheets doesn't have to be a daunting task. By understanding your requirements, choosing the right material, and partnering with a reliable supplier, you can streamline the process and ensure excellent results. Remember to provide detailed specifications, evaluate quotes thoroughly, and maintain clear communication throughout the ordering and production phases. With the right approach, you'll obtain precisely cut epoxy laminate sheets that meet your exact needs, contributing to the success of your projects and applications.

Contact Us

Ready to order your custom cut epoxy laminate sheets? Contact our experienced team at info@jhd-material.com for expert guidance and top-quality products tailored to your specifications. Let us help you bring your projects to life with precision-cut epoxy laminates that exceed your expectations.

References

1. Johnson, A. R. (2022). Advanced Epoxy Laminate Manufacturing Techniques. Journal of Composite Materials, 56(3), 412-428.

2. Smith, L. K., & Brown, T. H. (2021). Custom Cutting Technologies for High-Performance Laminates. Industrial Engineering Review, 18(2), 75-89.

3. Chen, X., & Zhang, Y. (2023). Optimizing Order Processes for Specialty Composite Materials. Supply Chain Management Quarterly, 37(1), 102-117.

4. Thompson, R. E. (2022). Quality Control in Custom-Cut Epoxy Laminates: Best Practices and Challenges. Materials Quality Assurance, 29(4), 301-315.

5. Patel, N., & Rodriguez, C. (2021). Innovations in Epoxy Laminate Sheet Applications across Industries. Advanced Materials Technology, 14(3), 228-242.

6. Yoshida, H., & Lee, S. (2023). Environmental Considerations in Epoxy Laminate Production and Customization. Sustainable Manufacturing Journal, 11(2), 157-171.