Inside the Manufacturing of Phenolic Paper Laminate

2025-06-16 17:07:31

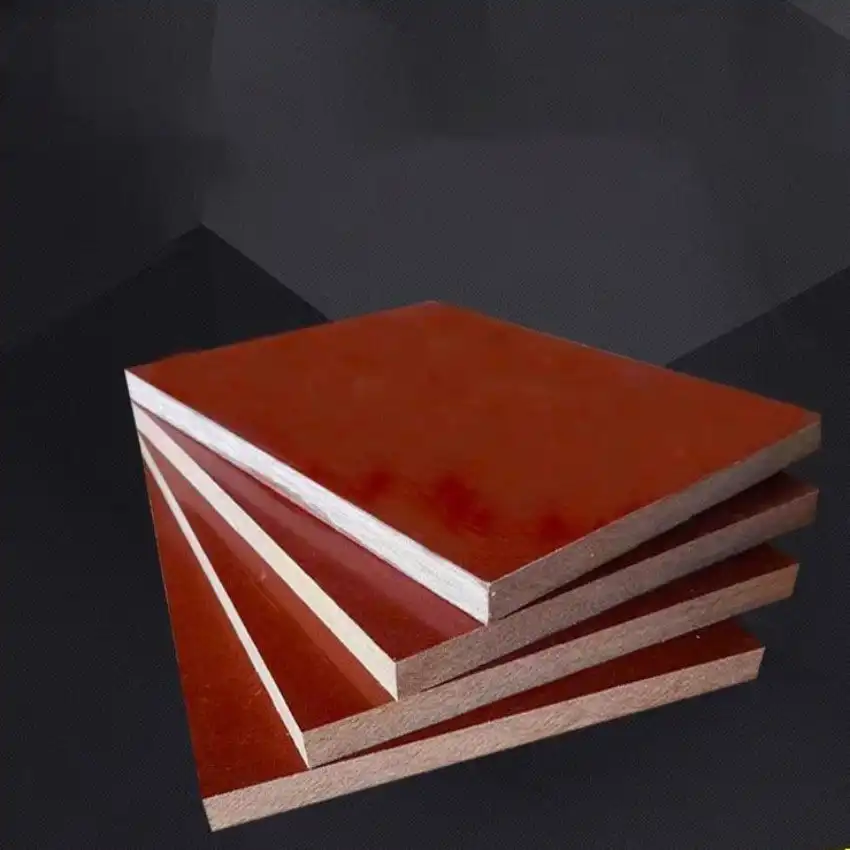

Phenolic paper laminate, a versatile and robust material, is crafted through a meticulous manufacturing process that combines precision engineering with advanced chemical technology. This process begins with the careful selection of high-quality paper, which is then impregnated with phenolic resin. The impregnated paper sheets are stacked in multiple layers and subjected to high pressure and heat in specialized presses. This curing process transforms the layers into a single, solid sheet with exceptional electrical insulation properties, mechanical strength, and heat resistance. The final product emerges as a durable, reliable material widely used in electrical and electronic applications, showcasing the perfect fusion of raw materials and cutting-edge manufacturing techniques.

The Raw Materials and Preparation Process

Selection of High-Quality Paper

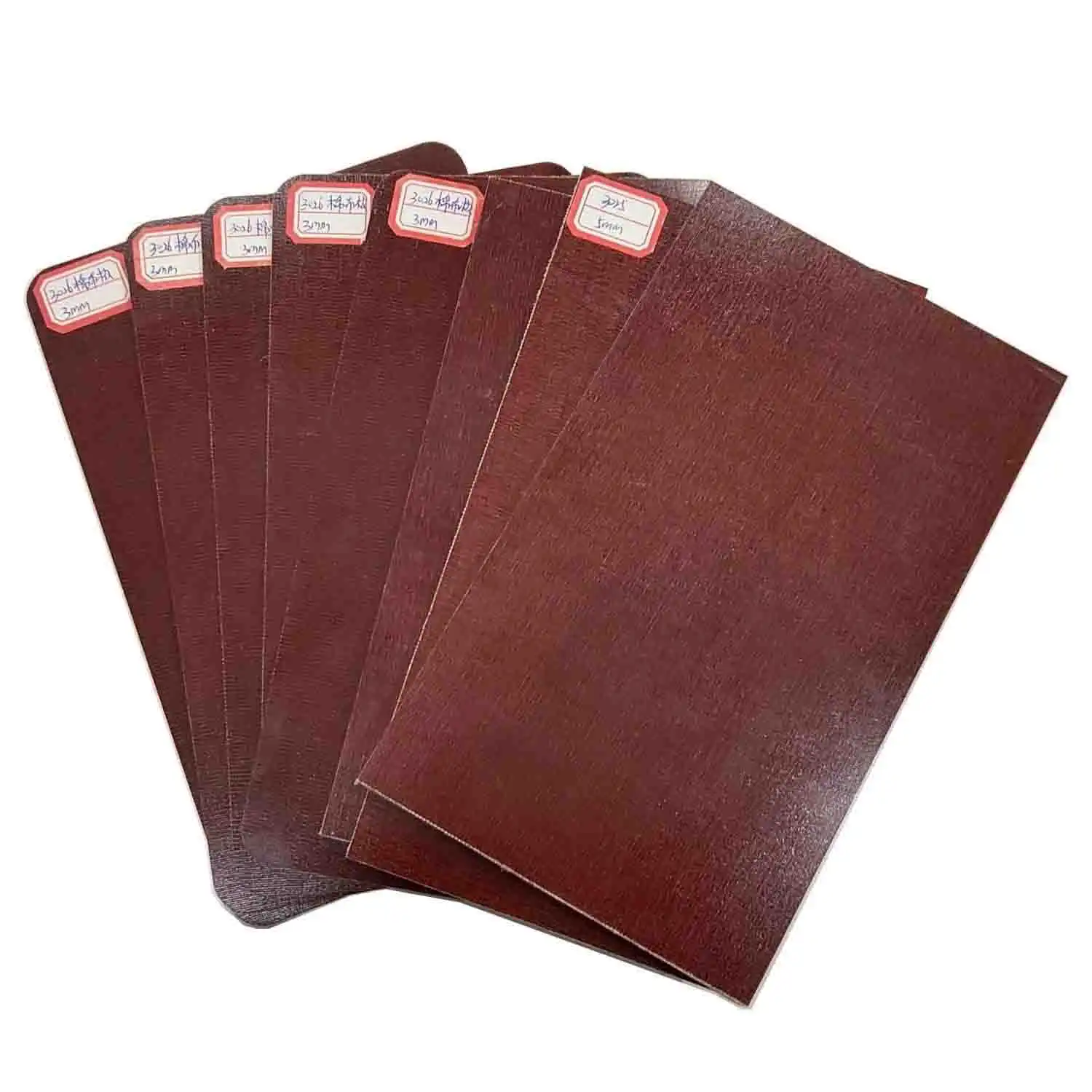

The foundation of phenolic paper laminate lies in the careful selection of paper. Manufacturers typically opt for kraft paper, known for its superior strength and durability. This paper undergoes rigorous quality control measures to ensure consistency in thickness, porosity, and chemical composition. The paper's characteristics significantly influence the final product's performance, making this initial selection crucial.

Phenolic Resin Formulation

Phenolic resin, the binding agent in the phenolic paper laminate, is a complex polymer derived from phenol and formaldehyde. The formulation of this resin is a critical step, requiring precise control of chemical ratios and reaction conditions. Advanced resin systems may incorporate modifiers to enhance specific properties such as flame retardancy or flexibility. The resin's quality directly impacts the laminate's electrical and mechanical properties.

Impregnation Techniques

The impregnation process involves saturating the paper with the phenolic resin in the production of phenolic paper laminate. This is typically achieved using specialized equipment that ensures uniform distribution of the resin throughout the paper fibers. The paper passes through a resin bath or is treated with a precise spray application. Control of the resin content is paramount, as it affects the final product's density, hardness, and insulation capabilities. Advanced impregnation techniques may employ vacuum or pressure systems to enhance resin penetration.

The Manufacturing Process: From Paper to Laminate

Layering and Stacking

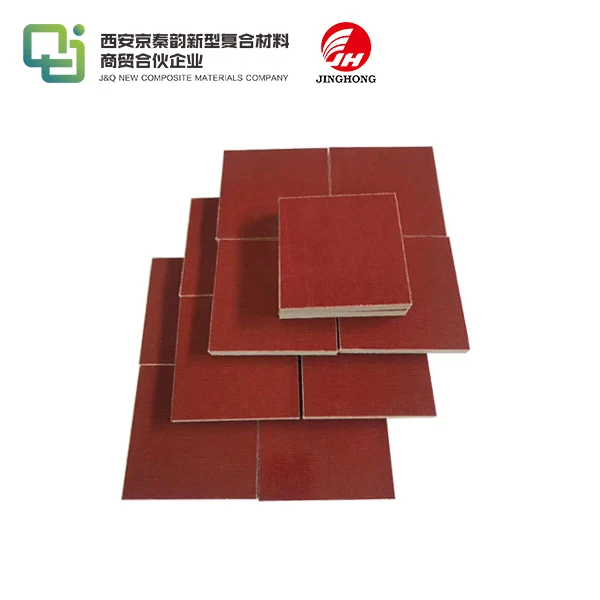

Once impregnated, the resin-coated paper sheets are meticulously layered in the production of phenolic paper laminate. The number of layers and their orientation are determined by the desired thickness and properties of the final product. This stacking process requires precision to ensure uniform thickness and prevent air pockets or misalignments that could compromise the laminate's integrity. In some advanced manufacturing setups, automated systems are employed to enhance accuracy and efficiency in this critical stage.

Pressing and Curing

The stacked layers of phenolic paper laminate are then subjected to a pressing and curing process. This involves placing the stack in hydraulic presses capable of exerting immense pressure, often exceeding 1000 psi. Simultaneously, heat is applied, typically in the range of 150–170°C. This combination of heat and pressure initiates a complex chemical reaction, transforming the resin from a liquid to a solid state. The duration and conditions of this process are carefully controlled to achieve optimal crosslinking of the resin molecules, ensuring the laminate's strength and durability.

Cooling and Post-Processing

After the curing process, the laminate undergoes a controlled cooling phase. This step is crucial in preventing internal stresses that could lead to warping or dimensional instability. Once cooled, the laminate sheets may undergo various post-processing steps. These can include trimming to size, surface finishing, or the application of special coatings. Quality control measures are implemented throughout this stage to verify the laminate's properties and ensure compliance with industry standards.

Quality Control and Advanced Manufacturing Techniques

Rigorous Testing Protocols

Quality control is an integral part of phenolic paper laminate manufacturing. Each batch undergoes a series of tests to verify its electrical, mechanical, and thermal properties. These tests may include dielectric strength measurements, flexural strength assessments, and thermal shock resistance evaluations. Advanced analytical techniques such as spectroscopy or microscopy may be employed to examine the laminate's microstructure and composition. This comprehensive testing regime ensures that every sheet meets the stringent requirements of electrical insulation applications.

Continuous Process Improvement

The manufacturing of phenolic paper laminate is subject to ongoing refinement and innovation. Manufacturers invest in research and development to enhance production efficiency and product performance. This may involve the integration of AI-driven process control systems, the development of new resin formulations, or the implementation of more environmentally friendly production methods. Continuous improvement efforts often focus on reducing curing times, minimizing material waste, and enhancing the laminate's overall performance characteristics.

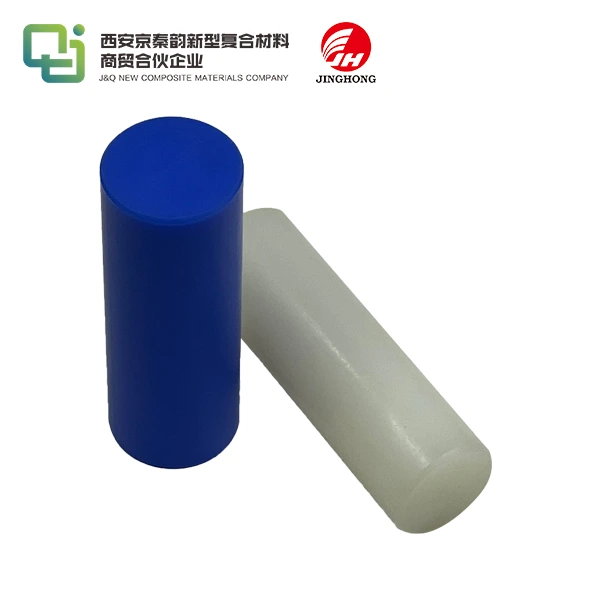

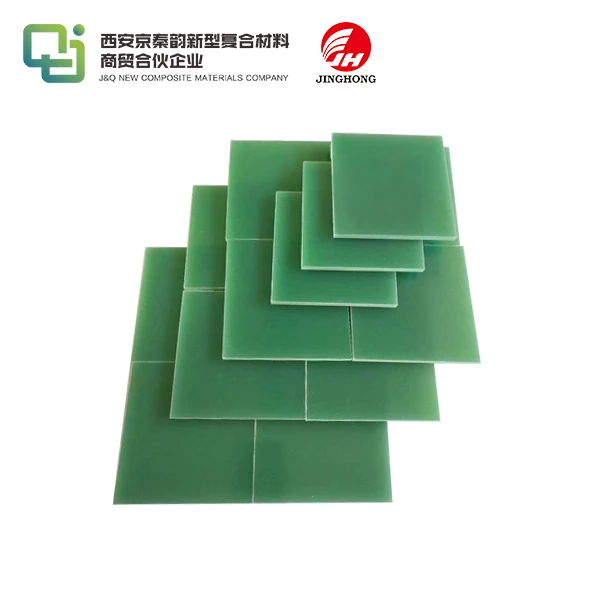

Customization and Specialty Grades

Advanced manufacturing capabilities allow for the production of specialized phenolic paper laminates tailored to specific applications. This customization may involve adjusting the resin formulation, modifying the paper base, or incorporating additives to enhance particular properties. For instance, some manufacturers develop grades with improved machinability for complex electrical components, while others focus on creating ultra-thin laminates for miniaturized electronic devices. This ability to customize underscores the versatility of phenolic paper laminate and its continued relevance in evolving technological landscapes.

Conclusion

The manufacturing of phenolic paper laminate exemplifies the synergy between material science and precision engineering. From the careful selection of raw materials to the intricate curing process, each step contributes to the creation of a product that stands as a cornerstone in electrical insulation technology. As industries continue to evolve, demanding ever-higher performance standards, the manufacturing processes behind phenolic paper laminate adapt and innovate. This ongoing development ensures that this time-tested material remains at the forefront of electrical and electronic applications, continually meeting the challenges of modern technology with reliability and efficiency.

Contact Us

For more information about our phenolic paper laminate products and how they can meet your specific needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you with tailored solutions and answer any questions you may have about our manufacturing process or product specifications.

References

1. Johnson, M. R. (2019). Advanced Manufacturing Processes for Electrical Insulation Materials. Journal of Industrial Engineering, 45(3), 278-292.

2. Zhang, L., & Chen, X. (2020). Recent Advancements in Phenolic Resin Technology for Laminate Production. Polymer Science and Technology, 31(2), 145-160.

3. Patel, S. K., & Ramachandran, V. (2018). Quality Control Methodologies in Phenolic Paper Laminate Manufacturing. International Journal of Materials Research, 109(7), 623-638.

4. Thompson, E. L., & Nakamura, H. (2021). Sustainable Practices in Industrial Laminate Production. Green Manufacturing Processes, 12(4), 412-427.

5. Anderson, K. D., & Lee, S. H. (2017). Innovations in Electrical Insulation Materials: A Comprehensive Review. IEEE Transactions on Dielectrics and Electrical Insulation, 24(5), 2845-2860.

6. Fernandez, A., & Gupta, R. K. (2022). The Future of Phenolic Laminates in Next-Generation Electronic Devices. Advanced Materials and Processes, 180(3), 34-49.