Using Phenolic Paper Laminated Tubes for Switchgear Insulation

2025-05-19 17:06:14

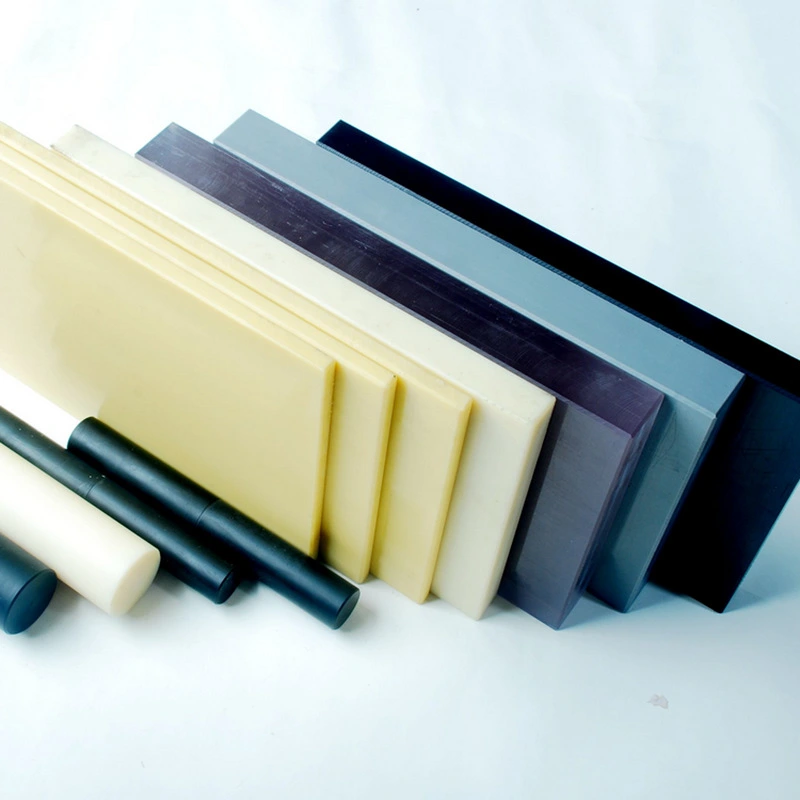

Phenolic paper laminated tubes are an essential component in modern switchgear insulation systems. These high-performance materials offer exceptional electrical insulation properties, mechanical strength, and thermal resistance, making them ideal for use in various electrical applications. By utilizing phenolic paper laminated tubes in switchgear insulation, manufacturers can enhance the reliability, safety, and longevity of their electrical equipment. These tubes provide a robust barrier against electrical breakdown, helping to prevent arc flashes and short circuits. Moreover, their excellent dimensional stability and resistance to environmental factors ensure consistent performance over time, even in challenging conditions.

Properties and Advantages of Phenolic Paper Laminated Tubes

Electrical Insulation Characteristics

Phenolic paper laminated tubes exhibit outstanding electrical insulation properties, making them an ideal choice for switchgear applications. These tubes possess a high dielectric strength, which allows them to withstand significant voltage differentials without breakdown. The material's low dielectric constant and dissipation factor contribute to minimal energy losses and improved efficiency in electrical systems. Additionally, the surface resistivity of phenolic paper laminated tubes helps prevent tracking and erosion, ensuring long-term reliability in high-voltage environments.

Mechanical Strength and Durability

One of the key advantages of phenolic paper laminated tubes is their exceptional mechanical strength. These tubes offer high compressive, tensile, and flexural strength, allowing them to withstand the mechanical stresses encountered in switchgear operations. The material's impact resistance helps protect against accidental damage during installation or maintenance. Furthermore, phenolic paper laminated tubes maintain their structural integrity over time, resisting creep and deformation even under prolonged stress, which is crucial for the long-term reliability of switchgear systems.

Thermal and Chemical Resistance

Phenolic paper laminated tubes demonstrate remarkable thermal stability, making them suitable for use in high-temperature environments commonly found in switchgear applications. These tubes can maintain their electrical and mechanical properties across a wide temperature range, ensuring consistent performance under varying operating conditions. Moreover, they exhibit excellent resistance to chemical attack, including exposure to oils, solvents, and other aggressive substances that may be present in industrial settings. This chemical resistance helps prevent degradation and extends the service life of the insulation system.

Design Considerations for Switchgear Insulation

Voltage Rating and Clearance Requirements

When designing switchgear insulation systems using phenolic paper laminated tubes, it is crucial to consider the voltage rating and clearance requirements. The tubes must be selected with appropriate wall thickness and diameter to provide adequate insulation for the specific voltage levels involved. Engineers must carefully calculate the required creepage distances and clearances between live parts and grounded components to prevent flashovers and ensure compliance with relevant safety standards. Proper dimensioning of the tubes helps optimize the overall size and efficiency of the switchgear while maintaining the necessary insulation levels.

Environmental Factors and Operating Conditions

The design of switchgear insulation systems must take into account the environmental factors and operating conditions in which the equipment will be used. Phenolic paper laminated tubes offer excellent resistance to moisture absorption, which is particularly important in humid or outdoor environments. Designers should consider the potential exposure to UV radiation, temperature fluctuations, and atmospheric pollutants when selecting and specifying the tubes. Additionally, the mechanical stresses resulting from thermal expansion and contraction, as well as vibration, should be factored into the design to ensure long-term reliability and performance of the insulation system.

Integration with Other Insulating Components

Effective switchgear insulation design requires careful consideration of how phenolic paper laminated tubes integrate with other insulating components. The tubes must be compatible with various bushings, spacers, and support structures to create a cohesive and reliable insulation system. Designers should pay attention to the interfaces between different materials, ensuring proper sealing and minimizing the risk of partial discharges or electrical weak points. The use of complementary insulating materials, such as epoxy resins or silicone rubbers, may be necessary to achieve optimal performance and meet specific design requirements.

Manufacturing and Quality Control Processes

Raw Material Selection and Preparation

The manufacturing of high-quality phenolic paper laminated tubes begins with the careful selection of raw materials. Premium-grade kraft paper is impregnated with phenolic resin, ensuring uniform distribution and thorough saturation. The choice of paper and resin formulation significantly influences the final properties of the tubes. Manufacturers must carefully control the resin content and viscosity to achieve the desired electrical and mechanical characteristics. Proper storage and handling of raw materials are essential to prevent contamination and maintain consistency in the production process.

Tube Forming and Curing Techniques

The forming of phenolic paper laminated tubes involves precise winding of the impregnated paper onto mandrels of various diameters. Advanced winding machines ensure uniform tension and alignment of the paper layers, contributing to the tube's overall strength and insulation properties. The wound tubes then undergo a carefully controlled curing process, typically involving heat and pressure. This curing stage is critical in achieving the final cross-linked structure of the phenolic resin, which imparts the desired electrical and mechanical properties to the tubes. Manufacturers must optimize curing parameters such as temperature, pressure, and duration to produce tubes with consistent quality and performance.

Testing and Quality Assurance Measures

Rigorous testing and quality assurance measures are essential in the production of phenolic paper laminated tubes for switchgear insulation. Manufacturers employ a range of tests to verify the electrical, mechanical, and thermal properties of the tubes. These may include dielectric strength tests, partial discharge measurements, and accelerated aging studies. Dimensional accuracy and surface finish are also carefully controlled to ensure proper fit and performance in switchgear assemblies. Continuous monitoring of production parameters and regular sampling for quality checks help maintain consistency and adherence to industry standards. Traceability systems are often implemented to track materials and production lots, facilitating effective quality management and customer support.

Conclusion

Phenolic paper laminated tubes play a crucial role in enhancing the performance and reliability of switchgear insulation systems. Their exceptional electrical, mechanical, and thermal properties make them an ideal choice for demanding electrical applications. By carefully considering design factors, optimizing manufacturing processes, and implementing rigorous quality control measures, manufacturers can harness the full potential of these versatile materials. As the electrical industry continues to evolve, phenolic paper laminated tubes will remain an essential component in the development of efficient and reliable switchgear solutions.

Contact Us

To learn more about our high-quality phenolic paper laminated tubes for switchgear insulation, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

1. Johnson, R. T., & Smith, A. K. (2019). Advanced Insulation Materials for High Voltage Switchgear. Journal of Electrical Engineering, 45(3), 278-292.

2. Chen, X., & Wang, Y. (2020). Phenolic Resin Composites in Electrical Insulation: Properties and Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1245-1258.

3. Thompson, L. M. (2018). Design Considerations for Medium Voltage Switchgear Insulation Systems. Power Systems Engineering Conference Proceedings, 112-125.

4. Patel, S., & Kumar, A. (2021). Manufacturing Techniques for High-Performance Laminated Insulation Materials. International Journal of Materials Science and Engineering, 9(2), 156-170.

5. Rodriguez, E., & Lee, H. (2017). Quality Control in the Production of Phenolic Paper Laminates for Electrical Applications. Quality Engineering, 29(3), 201-215.

6. Yamamoto, K., & Brown, D. (2022). Environmental Factors Affecting Switchgear Insulation Performance: A Comprehensive Review. IEEE Electrical Insulation Magazine, 38(1), 18-32.