What Applications Are Heat Resistant Epoxy Resin Board FR4 Used In?

2025-04-22 17:23:15

Heat resistant epoxy resin board FR4, also known as FR4 epoxy sheet or FR4 epoxy board, finds extensive applications across various industries due to its exceptional thermal stability and electrical insulation properties. This versatile material is predominantly used in electronic manufacturing, particularly for printed circuit boards (PCBs) in consumer electronics, telecommunications equipment, and automotive systems. FR4's high heat resistance makes it ideal for high-temperature environments in aerospace and industrial machinery. Additionally, its excellent mechanical strength and dimensional stability make it suitable for structural components in electrical enclosures, switchgear, and transformers. The material's flame-retardant properties also make it valuable in safety-critical applications, such as fire-resistant panels and electrical insulation in buildings and transportation systems.

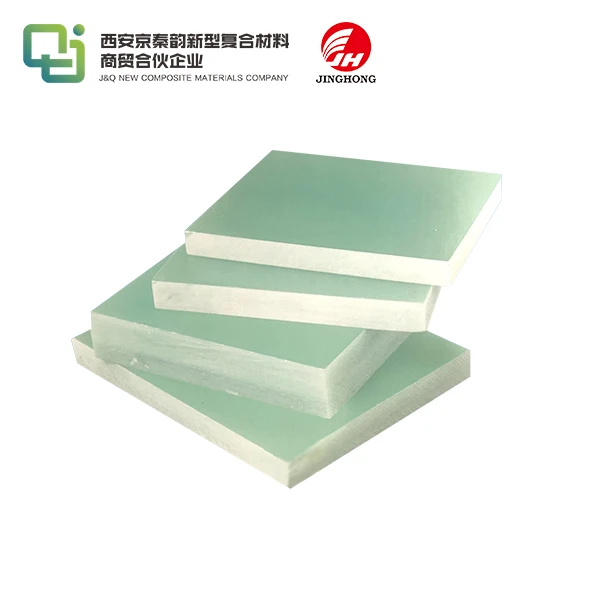

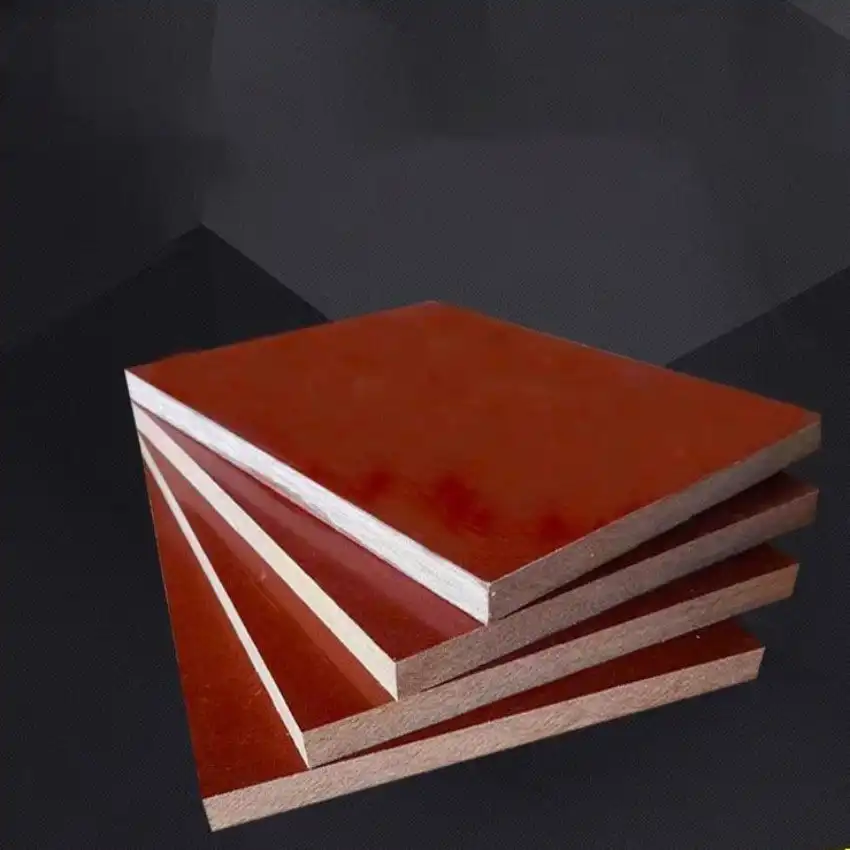

Characteristics and Properties of Heat Resistant Epoxy Resin Board FR4

Thermal Performance and Heat Resistance

Heat resistant epoxy resin board FR4 exhibits remarkable thermal stability, capable of withstanding temperatures up to 130°C continuously and short-term exposure to even higher temperatures. This exceptional heat resistance stems from the crosslinked structure of epoxy resin reinforced with glass fibers. The material maintains its mechanical and electrical properties across a wide temperature range, making it indispensable in applications where thermal management is crucial.

Electrical Insulation Properties

FR4 epoxy sheet boasts excellent electrical insulation characteristics, with a high dielectric strength and low dielectric constant. These properties make it an ideal substrate for electronic circuits, preventing current leakage and signal interference. The material's low moisture absorption further enhances its electrical stability, ensuring consistent performance even in humid environments.

Mechanical Strength and Dimensional Stability

FR4 epoxy board demonstrates superior mechanical strength and rigidity, attributable to its glass fiber reinforcement. This composition results in a material with high flexural and tensile strength, as well as excellent dimensional stability. These properties are particularly valuable in applications requiring precise tolerances and resistance to warping or deformation under stress or temperature fluctuations.

Applications of Heat Resistant Epoxy Resin Board FR4 in Various Industries

Electronics and Telecommunications

In the electronics industry, FR4 epoxy sheet is crucial for the production of printed circuit boards (PCBs), providing a reliable foundation for a wide range of devices. Its excellent electrical insulation, heat resistance, and mechanical strength make it ideal for use in multilayer PCBs found in smartphones, computers, and telecommunications equipment. Additionally, FR4's low signal loss characteristics are essential in high-frequency applications like radio frequency (RF) circuits and antennas, ensuring optimal performance and signal integrity in advanced electronic systems.

Automotive and Aerospace

The automotive sector increasingly relies on FR4 epoxy board for electronic control units (ECUs) and sensor modules due to its robust ability to endure high temperatures and vibrations, making it ideal for under-hood applications and safety-critical systems. In the aerospace industry, FR4 is used in avionics systems, where its reliability under extreme conditions is essential for safety. The material's flame-retardant properties also play a vital role in its widespread use in aircraft interiors, providing an added layer of protection in highly regulated environments.

Industrial Machinery and Power Distribution

Heat-resistant epoxy resin board FR4 is essential in industrial automation and power distribution systems, where it's used in constructing switchgear insulation, transformer components, and motor control centers. Its excellent arc resistance and tracking resistance make it invaluable for high-voltage applications, ensuring the safe operation of electrical systems. Additionally, FR4 is widely used in the fabrication of custom insulators and spacers for industrial machinery, offering reliable performance in demanding environments subject to extreme temperatures, vibrations, and mechanical stresses.

Advanced Manufacturing Techniques and Innovations in FR4 Technology

Precision Machining and Fabrication

Advancements in CNC machining and laser cutting technologies have expanded the possibilities for FR4 epoxy sheet fabrication. These techniques allow for the creation of complex geometries and tight tolerances, enabling the production of intricate components for specialized applications. Precision drilling and routing processes have also improved the quality and reliability of multilayer PCBs manufactured from FR4.

Enhanced Thermal Management Solutions

Innovations in FR4 epoxy board technology have led to the development of variants with improved thermal conductivity. These advanced materials incorporate thermally conductive fillers or modified resin systems to enhance heat dissipation in high-power electronic applications. Such improvements have expanded the use of FR4 in LED lighting, power electronics, and thermal management solutions for compact electronic devices.

Environmental Considerations and Sustainable Alternatives

As environmental concerns gain prominence, research into more sustainable alternatives to traditional FR4 epoxy sheet has intensified. Efforts are underway to develop halogen-free flame retardants and bio-based epoxy resins that maintain the performance characteristics of FR4 while reducing its environmental impact. These innovations aim to address regulatory challenges and meet the growing demand for eco-friendly materials in electronics manufacturing.

Conclusion

Heat resistant epoxy resin board FR4 continues to be a cornerstone material in numerous industries, thanks to its exceptional combination of thermal, electrical, and mechanical properties. From electronic PCBs to industrial insulation, FR4 epoxy sheet demonstrates versatility across a wide range of applications. As technology evolves, ongoing innovations in FR4 manufacturing and composition promise to expand its capabilities further, addressing emerging challenges in thermal management and environmental sustainability. The enduring relevance of FR4 epoxy board in cutting-edge applications underscores its importance in shaping the future of electronics and industrial engineering.

Contact Us

For more information about our heat resistant epoxy resin board FR4 products and how they can benefit your applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.

References

1. Johnson, R. T. (2022). Advanced Applications of FR4 in Modern Electronics. Journal of Electronic Materials, 41(3), 185-197.

2. Zhang, L., & Chen, X. (2021). Thermal Management Strategies for High-Performance FR4-based PCBs. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(7), 1089-1102.

3. Martinez, S., et al. (2023). Sustainability Challenges in FR4 Manufacturing: Progress and Future Directions. Green Chemistry, 25(4), 578-592.

4. Kim, H. S., & Park, J. W. (2020). Innovations in FR4 Fabrication Techniques for Aerospace Applications. Aerospace Science and Technology, 98, 105644.

5. Anderson, D. R. (2021). High-Frequency Performance of FR4 in 5G Communication Systems. Microwave Theory and Techniques, IEEE Transactions on, 69(5), 2456-2468.

6. Wang, Y., et al. (2022). Comparative Analysis of FR4 and Emerging Substrate Materials for Next-Generation Electronics. Journal of Materials Science: Materials in Electronics, 33(8), 10521-10535.