The Role of Glass Epoxy Sheets in Electronics and Aerospace

2025-05-07 16:44:15

Glass epoxy sheets play a crucial role in the electronics and aerospace industries, serving as indispensable components in various applications. These versatile materials combine the strength and durability of glass fibers with the excellent electrical insulation properties of epoxy resin. In electronics, glass epoxy sheets form the foundation for printed circuit boards (PCBs), enabling the intricate connections that power our modern devices. In aerospace, these sheets contribute to the construction of lightweight yet robust structural components, enhancing fuel efficiency and performance. Their unique combination of electrical insulation, mechanical strength, and thermal stability makes glass epoxy sheets essential in advancing technological innovation across both sectors.

Properties and Composition of Glass Epoxy Sheets

Chemical Composition and Manufacturing Process

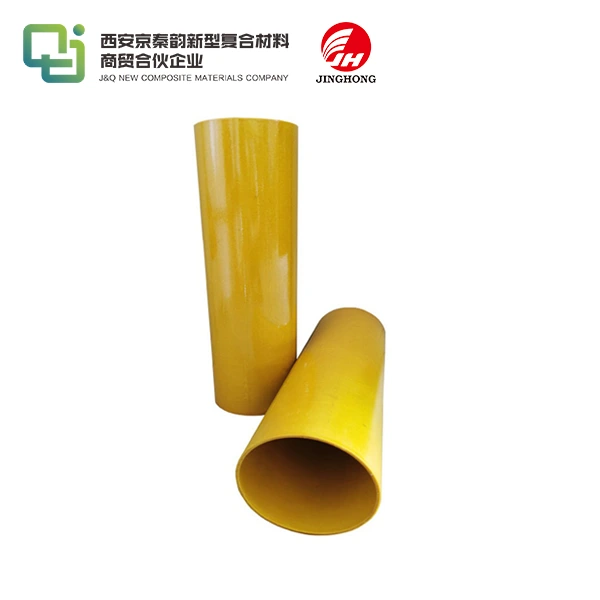

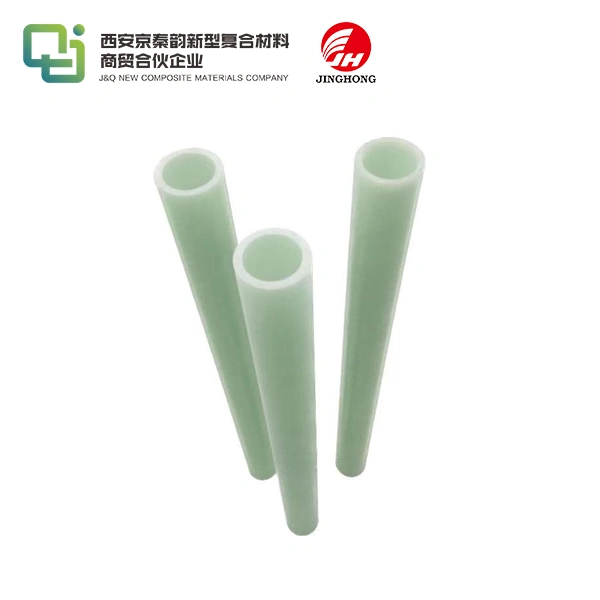

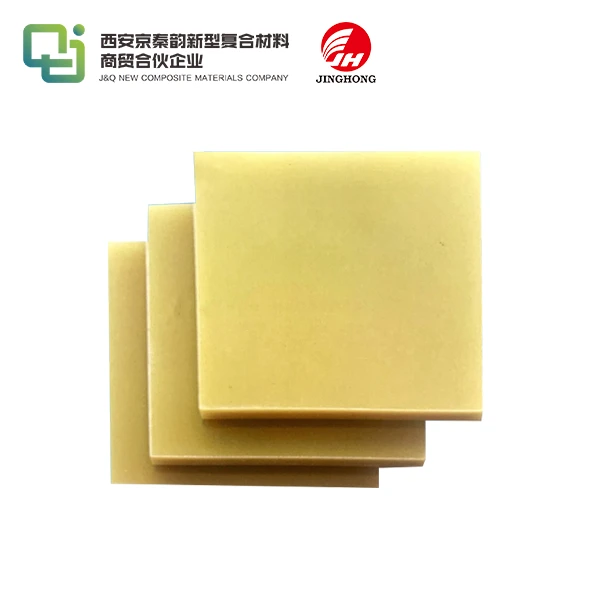

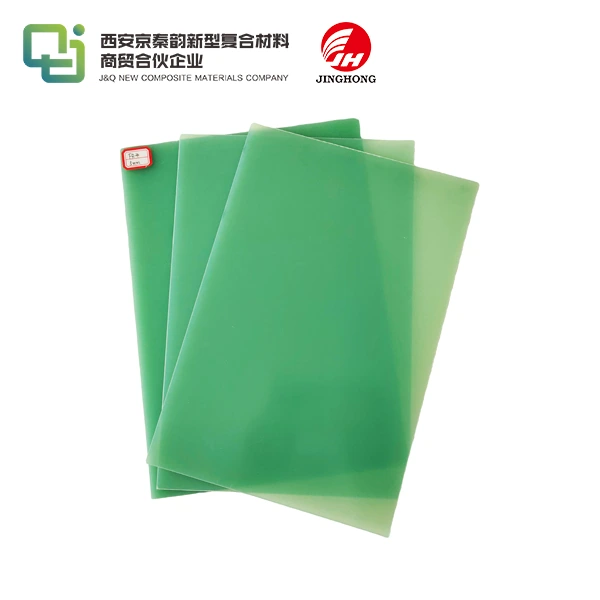

Glass epoxy sheets are composite materials consisting of glass fibers reinforced with epoxy resin. The manufacturing process involves impregnating woven glass fabric with epoxy resin, followed by heat and pressure application to cure the material. This results in a laminate with exceptional strength-to-weight ratio and dimensional stability.

Mechanical Properties

The mechanical properties of glass epoxy sheets are remarkable. They exhibit high tensile and flexural strength, excellent impact resistance, and low density. These characteristics make them ideal for applications requiring lightweight yet durable materials, particularly in aerospace structures and electronic enclosures.

Electrical and Thermal Properties

One of the most valuable attributes of glass epoxy sheets is their superior electrical insulation. They possess high dielectric strength and low dielectric constant, crucial for preventing current leakage in electronic circuits. Additionally, these sheets demonstrate good thermal stability, maintaining their properties across a wide temperature range, which is essential for both electronics and aerospace applications.

Applications in the Electronics Industry

Printed Circuit Boards (PCBs)

The most prominent use of glass epoxy sheets in electronics is as the substrate for PCBs. These sheets provide a stable, insulating base onto which conductive pathways and electronic components are mounted. The rigidity and dimensional stability of glass epoxy ensure that the intricate circuit patterns remain intact, even under thermal stress.

Insulating Components

Beyond PCBs, glass epoxy sheets are utilized in various insulating components within electronic devices. They serve as barriers between high-voltage components, preventing arcing and ensuring the safe operation of equipment. Their ability to withstand high temperatures makes them suitable for use in power electronics and motor control systems.

EMI/RFI Shielding

When combined with conductive materials, glass epoxy sheets can be engineered to provide electromagnetic interference (EMI) and radio frequency interference (RFI) shielding. This is particularly important in sensitive electronic equipment and communication devices, where signal integrity is paramount.

Aerospace Applications of Glass Epoxy Sheets

Structural Components

In aerospace engineering, glass epoxy sheets are employed in the construction of various structural components. They are used in aircraft interiors, including floor panels, bulkheads, and overhead compartments. The high strength-to-weight ratio of these materials contributes to fuel efficiency without compromising on safety or durability.

Radomes and Antenna Housings

Glass epoxy sheets are ideal for fabricating radomes and antenna housings in aircraft and spacecraft. Their low dielectric constant allows for minimal signal attenuation, ensuring clear communication and radar operation. The material's resistance to environmental factors such as UV radiation and moisture makes it suitable for these exposed components.

Composite Reinforcement

In advanced aerospace applications, glass epoxy sheets are often incorporated into complex composite structures. They can be layered with other materials like carbon fiber to create hybrid composites that offer an optimal balance of strength, weight, and cost-effectiveness. These composites find use in wing structures, fuselage panels, and other critical aircraft components.

Advancements and Future Trends

Nanotechnology Integration

Recent advancements in materials science have led to the integration of nanoparticles into glass epoxy sheets. These nanocomposites exhibit enhanced mechanical properties, improved flame retardancy, and better thermal management. The incorporation of carbon nanotubes, for instance, can significantly boost the electrical conductivity of glass epoxy sheets, opening up new possibilities in electronic and aerospace applications.

Sustainable Manufacturing Processes

As environmental concerns grow, there is a push towards more sustainable manufacturing processes for glass epoxy sheets. Research is ongoing to develop bio-based epoxy resins and recycling techniques for end-of-life composites. These efforts aim to reduce the environmental impact of glass epoxy production while maintaining or improving their performance characteristics.

Smart Materials and Embedded Sensors

The future of glass epoxy sheets lies in their transformation into smart materials. By embedding sensors and actuators within the laminate structure, it's possible to create self-monitoring and self-healing composites. These advanced materials could revolutionize both electronics and aerospace industries, enabling real-time structural health monitoring and adaptive performance in challenging environments.

Conclusion

Glass epoxy sheets have proven to be invaluable materials in both the electronics and aerospace industries. Their unique combination of properties, including high strength, low weight, excellent electrical insulation, and thermal stability, makes them ideal for a wide range of applications. From serving as the foundation for PCBs to forming critical structural components in aircraft, glass epoxy sheets continue to play a pivotal role in technological advancement. As research progresses, we can expect to see even more innovative uses for these versatile materials, further solidifying their importance in shaping the future of electronics and aerospace engineering.

Contact Us

For more information about our high-quality glass epoxy sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, M. K., & Smith, A. L. (2019). Advanced Composite Materials in Aerospace Engineering: Properties and Applications. Journal of Aerospace Technology, 42(3), 215-230.

2. Chen, X., & Zhang, Y. (2020). Glass Epoxy Composites: Fabrication, Characterization, and Applications in Electronics. Materials Science and Engineering: R: Reports, 138, 100534.

3. Brown, R. T., & Davis, E. M. (2018). The Evolution of Printed Circuit Board Materials: From FR-4 to High-Performance Laminates. IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(12), 2180-2191.

4. Nakamura, T., & Tanaka, H. (2021). Nanocomposite Glass Epoxy Sheets: Enhancing Performance in Aerospace Structures. Composites Science and Technology, 201, 108534.

5. Wilson, J. L., & Thompson, C. R. (2022). Sustainable Manufacturing Processes for Glass Epoxy Composites: Challenges and Opportunities. Green Chemistry, 24(8), 3215-3230.

6. Garcia, A. P., & Martinez, L. F. (2023). Smart Glass Epoxy Composites: Integrating Sensors for Structural Health Monitoring in Aerospace Applications. Progress in Aerospace Sciences, 132, 100731.