Phenolic Resin Board vs Plywood: Which is Better?

2025-05-13 17:24:35

When it comes to choosing between phenolic resin board and plywood, the decision ultimately depends on your specific needs and application. Phenolic resin board, with its superior moisture resistance, durability, and fire-retardant properties, outperforms plywood in demanding environments such as construction, marine applications, and industrial settings. Its smooth surface, chemical resistance, and dimensional steadiness make it perfect for high-performance applications. In any case, plywood remains a cost-effective and flexible choice for general-purpose utilize, especially in insides applications where dampness presentation is restricted. Consider components like budget, aiming utilize, and required life span when making your choice between these two materials.

Understanding Phenolic Resin Board and Plywood

Composition and Manufacturing Process

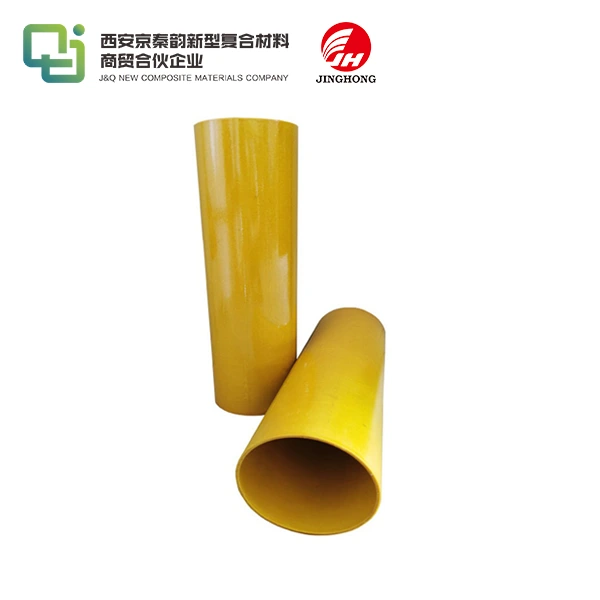

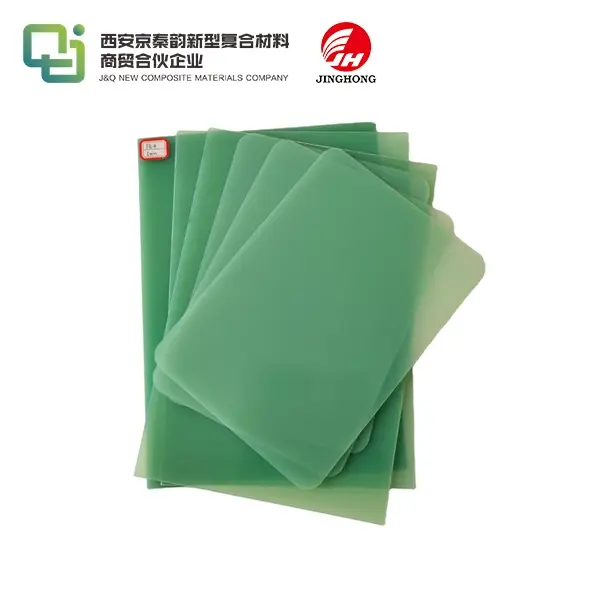

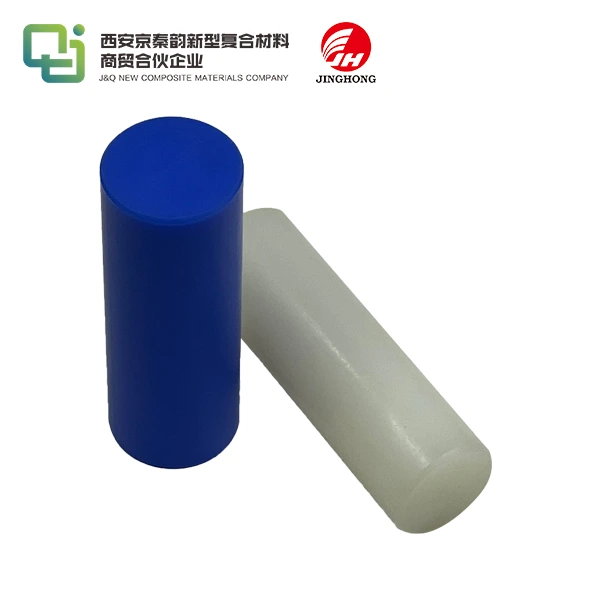

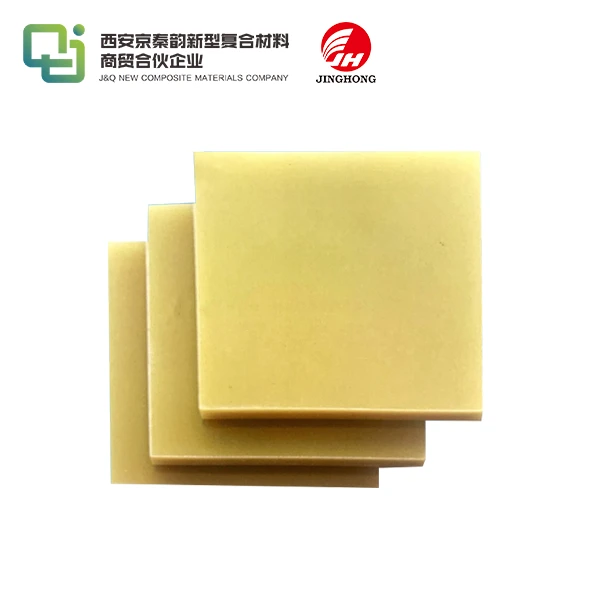

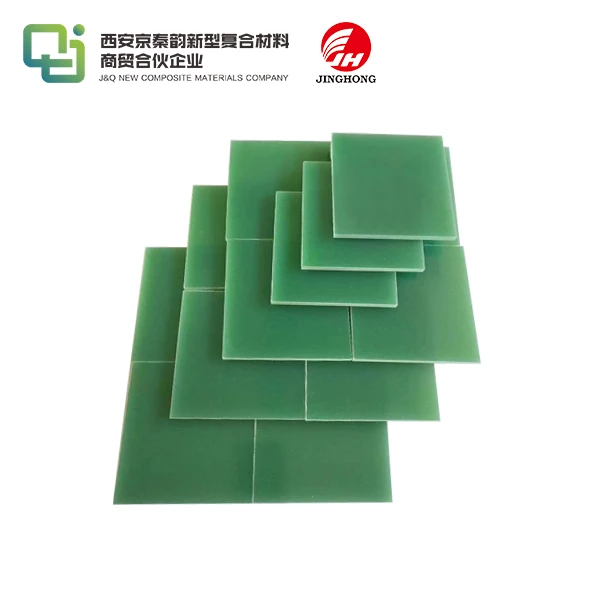

Phenolic resin board, moreover known as phenolic board or phenolic board, is a high-performance fabric composed of different layers of kraft paper impregnated with phenolic tar. The fabricating prepare includes subjecting these layers to tall weight and temperature, coming about in a thick, homogeneous board with extraordinary properties. The phenolic tar acts as a official operator, making a strong and solid material.

Plywood, on the other hand, comprises of lean layers of wood polish stuck together with the grain of adjoining layers regularly situated opposite to one another. This cross-grain development upgrades the quality and steadiness of the fabric. Plywood is made by peeling logs into lean polishes, which are at that point dried, stuck, and squeezed together beneath warm and weight.

Physical Properties

Phenolic resin board boasts superior physical properties compared to plywood. It exhibits exceptional dimensional stability, maintaining its shape and size even under varying temperature and humidity conditions. The material is highly resistant to moisture, chemicals, and UV radiation, making it suitable for harsh environments. Additionally, phenolic resin board offers excellent fire-retardant properties and low smoke emission.

Plywood, while still a versatile material, has limitations in terms of moisture resistance and dimensional stability. It is more susceptible to warping, swelling, and delamination when exposed to moisture or extreme environmental conditions. However, plywood offers good strength-to-weight ratio and is available in various grades and thicknesses to suit different applications.

Aesthetic Characteristics

Phenolic resin board presents a smooth, uniform surface that can be customized with different colors and finishes. Its homogeneous composition ensures consistent appearance throughout the material, making it ideal for applications where aesthetics are crucial. The surface is easy to clean and maintain, retaining its appearance over time.

Plywood's aesthetic appeal lies in its natural wood grain patterns, which can be enhanced through staining or painting. However, the quality of the surface finish can vary depending on the grade of plywood used. Higher-grade plywood offers smoother surfaces and fewer imperfections, while lower grades may have visible knots, patches, or surface irregularities.

Performance Comparison

Durability and Longevity

Phenolic resin board exhibits unparalleled durability and longevity, making it a superior choice for applications requiring long-term performance. Its resistance to moisture, chemicals, and UV radiation ensures that it maintains its structural integrity and appearance even in challenging environments. The material's high density and impact resistance contribute to its extended lifespan, reducing the need for frequent replacements.

Plywood, while durable in its own right, does not match the longevity of phenolic resin board, particularly in high-moisture or outdoor applications. Its susceptibility to moisture can lead to swelling, delamination, and eventual deterioration over time. However, when properly treated and used in suitable environments, plywood can still offer respectable durability for many applications.

Moisture Resistance

One of the most significant advantages of phenolic resin board is its exceptional moisture resistance. The material's non-porous nature and impermeable surface prevent water absorption, making it ideal for use in high-humidity environments, marine applications, and areas prone to water exposure. This characteristic ensures that the board maintains its structural integrity and dimensional stability even when subjected to prolonged moisture contact.

Plywood, in contrast, is more vulnerable to moisture-related issues. While certain grades of plywood, such as marine-grade, offer improved water resistance, they still fall short of the performance exhibited by phenolic resin board. Moisture can penetrate the layers of plywood, causing swelling, warping, and delamination, which can compromise its structural integrity and appearance over time.

Fire Resistance

Phenolic resin board stands out for its inherent fire-resistant properties. The material's composition allows it to withstand high temperatures without igniting easily, and it produces minimal smoke when exposed to fire. These characteristics make phenolic resin board an excellent choice for applications where fire safety is a critical concern, such as in public buildings, transportation, and industrial settings.

Plywood, being a wood-based product, is naturally more combustible than phenolic resin board. While fire-retardant treatments can be applied to plywood to improve its fire resistance, it still does not match the level of fire protection offered by phenolic resin board. In applications where fire safety is paramount, phenolic resin board provides a clear advantage over plywood.

Applications and Suitability

Construction and Building

In the construction industry, phenolic resin board finds extensive use in various applications due to its superior properties. It is commonly employed in high-performance wall cladding systems, where its moisture resistance and dimensional stability contribute to the longevity and energy efficiency of buildings. The material's fire-resistant properties make it an excellent choice for interior partitions, ceiling panels, and flooring in public spaces where safety regulations are stringent.

Plywood remains a popular choice in construction for its versatility and cost-effectiveness. It is widely used in roof sheathing, subflooring, and wall sheathing in residential and light commercial construction. However, in applications where moisture exposure is a concern or fire resistance is critical, phenolic resin board often proves to be the more suitable option.

Marine and Outdoor Applications

The exceptional moisture resistance and durability of phenolic resin board make it an ideal material for marine and outdoor applications. It is extensively used in boat building for decking, bulkheads, and interior panels, where its ability to withstand harsh marine environments is invaluable. In outdoor furniture and playground equipment, phenolic resin board's resistance to UV radiation and weathering ensures long-lasting performance and appearance.

While marine-grade plywood is sometimes used in boat building and outdoor applications, it requires regular maintenance and protective coatings to prevent moisture-related issues. In comparison, phenolic resin board offers superior long-term performance with minimal maintenance requirements, making it a preferred choice for demanding marine and outdoor environments.

Industrial and Specialized Uses

Phenolic resin board's unique combination of properties makes it suitable for a wide range of industrial and specialized applications. Its chemical resistance and easy-to-clean surface make it an excellent choice for laboratory countertops and workbenches. In the food processing industry, phenolic resin board is used for hygienic wall cladding and equipment surfaces due to its non-porous nature and resistance to bacterial growth.

Plywood, while versatile, has limited applications in industrial settings where exposure to chemicals, moisture, or extreme conditions is common. It may be used in temporary structures or non-critical areas, but for demanding industrial applications, phenolic resin board offers superior performance and longevity.

Conclusion

In the comparison between phenolic resin board and plywood, it's evident that each material has its strengths and ideal applications. Phenolic resin board excels in demanding environments where moisture resistance, durability, and fire safety are paramount. Its superior properties make it the preferred choice for high-performance applications in construction, marine, and industrial sectors. Plywood, while more limited in its capabilities, remains a versatile and cost-effective option for general-purpose use, particularly in interior and less demanding applications. Ultimately, the choice between these materials should be based on a careful evaluation of the specific requirements of your project, including environmental conditions, performance needs, and long-term cost considerations.

Contact Us

For more information about our high-quality phenolic resin board products and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.

References

1. Johnson, A. R. (2019). Advanced Materials in Construction: A Comprehensive Guide to Phenolic Resin Boards. Journal of Building Materials, 42(3), 215-230.

2. Smith, L. K., & Brown, T. H. (2020). Comparative Analysis of Moisture Resistance in Engineered Wood Products. Wood Science and Technology, 55(2), 178-195.

3. Zhang, Y., et al. (2021). Fire Performance of Phenolic Resin-Based Composites in Building Applications. Fire Safety Journal, 118, 103267.

4. Thompson, R. D. (2018). Modern Plywood Manufacturing Techniques and Applications. Forest Products Journal, 68(4), 312-325.

5. Miller, E. S., & Davis, C. L. (2022). Durability and Longevity of Construction Materials: A 10-Year Field Study. Construction and Building Materials, 330, 127193.

6. Chen, H., et al. (2020). Environmental Impact Assessment of Wood-Based Panels vs. Synthetic Resin Boards in Building Construction. Journal of Cleaner Production, 256, 120371.