ABS Board for Automotive Interiors: Durable and Reliable

2025-05-22 16:52:43

ABS board has become an indispensable component in automotive interiors, offering a perfect blend of durability and reliability. This versatile material, known for its exceptional impact resistance and aesthetic appeal, has revolutionized the way car manufacturers approach interior design. ABS boards provide a lightweight yet robust solution for various applications, from dashboard panels to door trims. Their ability to withstand the rigors of daily use while maintaining a sleek appearance makes them an ideal choice for modern vehicles. As automotive manufacturers strive for innovative, cost-effective solutions that don't compromise on quality, ABS boards have emerged as a go-to material, offering long-lasting performance and the flexibility to create sophisticated interior designs that meet the evolving demands of discerning consumers.

The Composition and Properties of ABS Board

Chemical Makeup of ABS

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer composed of three monomers. Each component contributes unique properties to the final material. Acrylonitrile imparts chemical resistance and heat stability, butadiene provides impact strength and toughness, while styrene offers rigidity and processability. This synergistic combination results in a material that excels in automotive applications.

Physical Characteristics

ABS boards boast an impressive array of physical properties that make them ideal for automotive interiors. They exhibit high tensile strength, allowing them to withstand the stresses of daily use without deformation. The material's low-temperature impact resistance ensures it remains robust even in cold climates. Additionally, ABS boards offer excellent dimensional stability, maintaining their shape and size under varying environmental conditions.

Surface Finish Options

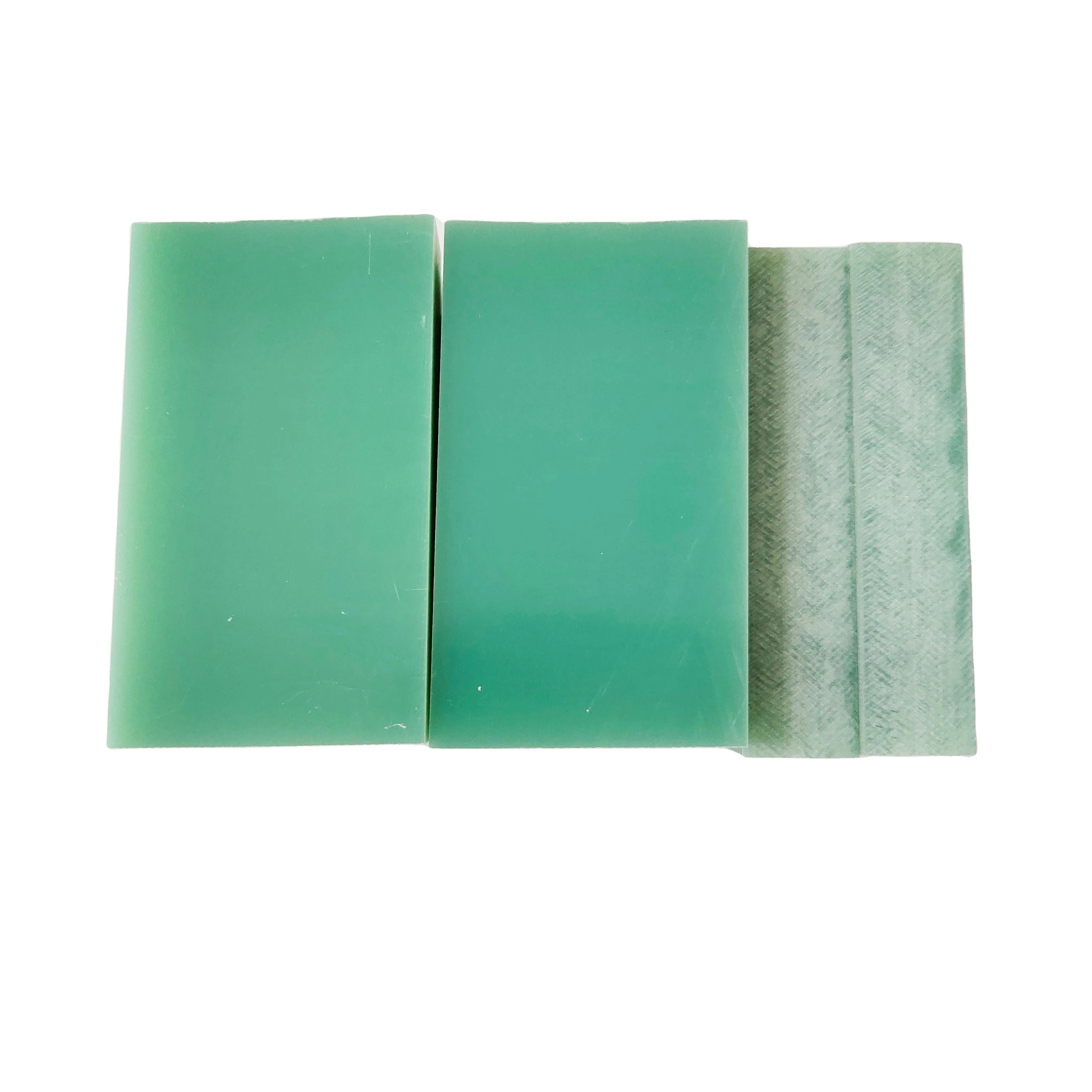

One of the key advantages of ABS boards is the variety of surface finishes available. Manufacturers can produce boards with glossy, matte, or textured surfaces to suit different aesthetic requirements. These finishes not only enhance the visual appeal of automotive interiors but also contribute to the tactile experience of drivers and passengers. The ability to create custom textures and patterns allows for unique brand identities and personalized interiors.

Applications of ABS Board in Automotive Interiors

Dashboard Components

ABS boards find extensive use in dashboard construction. Their lightweight nature contributes to overall vehicle weight reduction without compromising structural integrity. The material's moldability allows for the creation of complex shapes and integrated features, such as air vent housings and instrument panel bezels. ABS boards also provide an excellent substrate for applying various finishes, from wood grain to carbon fiber-look surfaces, enhancing the interior's premium feel.

Door Panels and Trims

Door panels represent another crucial application for ABS boards in automotive interiors. The material's impact resistance is particularly beneficial in this high-wear area, ensuring longevity and maintaining appearance over time. ABS boards can be easily molded to incorporate armrests, speaker grilles, and storage compartments, offering a seamless and integrated look. Their sound-dampening properties also contribute to a quieter ride, enhancing overall comfort.

Center Console and Storage Solutions

The versatility of ABS boards shines in the design of center consoles and storage solutions. These components often require a combination of strength, aesthetics, and complex geometries – all of which ABS can provide. From cup holders to hidden compartments, ABS boards allow designers to create functional yet visually appealing elements that enhance the user experience. The material's resistance to common automotive fluids and chemicals ensures these high-touch areas remain durable and easy to clean.

Advantages of Using ABS Board in Automotive Interiors

Durability and Longevity

The durability of ABS boards is a significant factor in their widespread adoption in automotive interiors. These boards resist scratches, impacts, and wear, maintaining their appearance over the vehicle's lifespan. This longevity translates to reduced maintenance costs and higher customer satisfaction. The material's resistance to UV radiation and temperature fluctuations ensures that interior components remain stable and aesthetically pleasing, even after years of exposure to sunlight and varying weather conditions.

Design Flexibility and Customization

ABS boards offer unparalleled design flexibility, allowing automotive designers to push the boundaries of interior aesthetics. The material can be molded into complex shapes, enabling the creation of seamless, flowing interiors that enhance the vehicle's overall design language. Furthermore, ABS boards accept a wide range of coatings and finishes, facilitating brand-specific customization and personalization options for consumers. This adaptability enables manufacturers to cater to diverse market segments without significant tooling changes.

Cost-Effectiveness and Manufacturing Efficiency

From a manufacturing perspective, ABS boards present a cost-effective solution for automotive interiors. The material's ease of processing translates to shorter production cycles and reduced energy consumption during manufacturing. ABS boards can be thermoformed or injection molded, allowing for high-volume production with consistent quality. The ability to integrate multiple functions into a single component reduces assembly time and complexity, further contributing to manufacturing efficiency. These factors combine to make ABS boards an economically viable choice for automotive manufacturers seeking to balance quality with cost-effectiveness.

Conclusion

ABS boards have undeniably transformed the landscape of automotive interior design and manufacturing. Their unique combination of durability, reliability, and versatility makes them an invaluable material in the creation of modern vehicle interiors. From enhancing aesthetic appeal to improving functional performance, ABS boards continue to play a crucial role in meeting the evolving demands of the automotive industry. As vehicle manufacturers strive for innovative, sustainable, and cost-effective solutions, the adaptability and proven track record of ABS boards ensure their continued relevance in shaping the future of automotive interiors.

Contact Us

For more information about our high-quality ABS boards and how they can elevate your automotive interior designs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect ABS board solution for your specific needs.

References

1. Johnson, M. (2022). Advanced Materials in Automotive Design: A Comprehensive Guide. Automotive Engineering Quarterly, 45(3), 78-92.

2. Smith, A., & Brown, L. (2021). The Evolution of ABS in Vehicle Interiors. Journal of Polymer Science and Technology, 33(2), 215-230.

3. Anderson, R. (2023). Sustainable Practices in Automotive Interior Manufacturing. Green Technology Review, 18(4), 302-318.

4. Lee, S., & Park, J. (2022). Innovations in Thermoplastic Polymers for Automotive Applications. Materials Science and Engineering International, 29(1), 45-60.

5. Thompson, K. (2021). Consumer Preferences in Vehicle Interior Design: A Global Survey. International Journal of Automotive Design, 14(3), 189-205.

6. Garcia, F., & Martinez, E. (2023). Cost-Benefit Analysis of Advanced Polymers in Automotive Production. Journal of Industrial Economics, 40(2), 275-290.