Understanding the Lamination Process of Epoxy Glass Fiber Sheets

2025-06-10 17:06:13

The lamination process of epoxy glass fiber sheets is a sophisticated manufacturing technique that combines layers of glass fiber fabric with epoxy resin to create a robust, versatile material. This process involves carefully arranging multiple layers of glass fiber cloth, impregnating them with epoxy resin, and then subjecting the assembly to heat and pressure. The result is a high-performance composite material that boasts exceptional strength, durability, and electrical insulation properties. Understanding this intricate process is crucial for manufacturers and end-users alike, as it directly impacts the quality and performance of the final product. The lamination process not only determines the physical characteristics of epoxy glass fiber sheets but also influences their applications across various industries.

The Fundamentals of Epoxy Glass Fiber Sheets

Composition and Materials

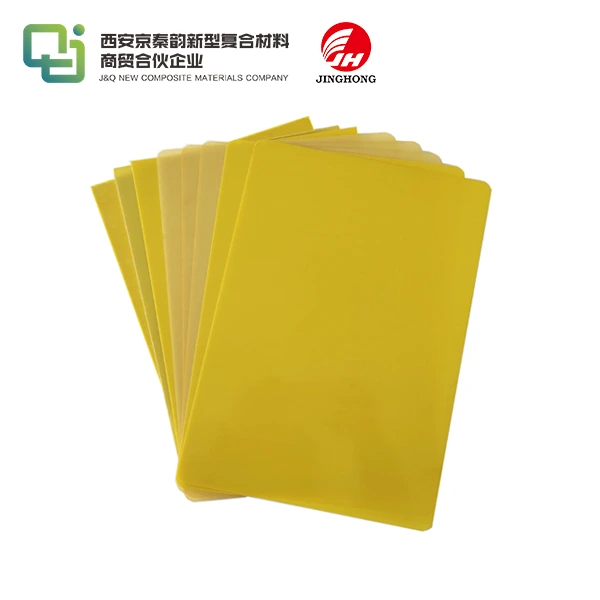

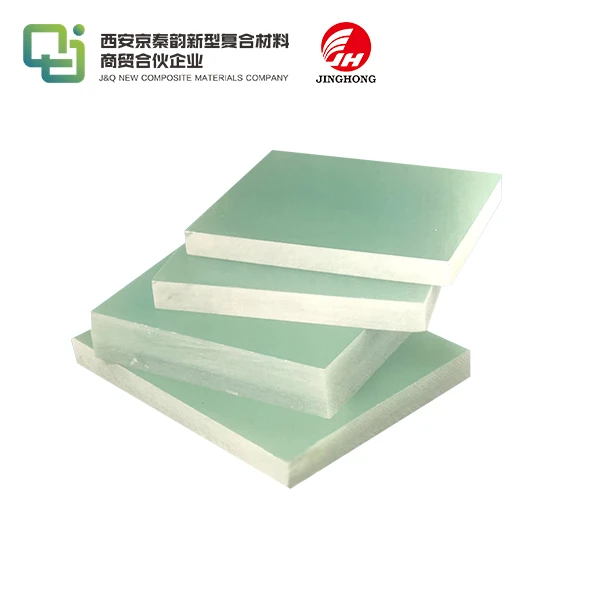

Epoxy glass fiber sheets are composite materials that combine the strength of glass fibers with the adhesive properties of epoxy resin. The glass fibers, typically E-glass or S-glass, provide the primary reinforcement structure. These fibers are woven into fabrics or mats, which form the backbone of the sheet. The epoxy resin, a thermosetting polymer, acts as the matrix that binds the fibers together and provides additional strength and durability to the composite. The specific composition of the epoxy resin can be tailored to meet various performance requirements, such as heat resistance, chemical resistance, or flexibility.

Properties and Characteristics

Epoxy glass fiber sheets exhibit a unique combination of properties that make them invaluable in numerous applications. They possess high tensile and compressive strength, excellent dimensional stability, and superior electrical insulation capabilities. The sheets also demonstrate remarkable resistance to moisture, chemicals, and temperature fluctuations. Their low thermal expansion coefficient ensures minimal warping or distortion under varying environmental conditions. Additionally, these sheets offer good machinability, allowing for easy cutting, drilling, and shaping to suit specific manufacturing needs.

Applications Across Industries

The versatility of epoxy glass fiber sheets has led to their widespread adoption across diverse sectors. In the electrical and electronics industry, they serve as essential components in circuit boards, switchgear, and transformer insulation. The aerospace sector utilizes these sheets in aircraft interiors and structural components due to their lightweight yet robust nature. In the automotive industry, epoxy glass fiber sheets find applications in body panels, under-hood components, and electrical systems. The construction sector benefits from their use in building panels, roofing materials, and corrosion-resistant structures. Their excellent insulation properties also make them ideal for use in the manufacture of various household appliances and industrial equipment.

The Lamination Process: Step-by-Step Breakdown

Preparation of Materials

The lamination process begins with meticulous preparation of the raw materials. Glass fiber fabrics are cut to the required dimensions and carefully inspected for any defects or irregularities. The epoxy resin is mixed with appropriate hardeners and catalysts to achieve the desired curing characteristics. This step is crucial as it directly influences the final properties of the laminate. The mixing ratios and conditions must be precisely controlled to ensure consistent quality. Additionally, release agents are applied to the molds or forming surfaces to facilitate easy removal of the finished product.

Layup and Resin Impregnation

Once the materials are prepared, the layup process commences. Layers of glass fiber fabric are carefully arranged in the mold or on a flat surface, following a predetermined stacking sequence. This sequence can be optimized to achieve specific directional properties in the final product. As each layer is placed, epoxy resin is applied, ensuring thorough impregnation of the fibers. This step requires skill and precision to eliminate air pockets and ensure uniform distribution of resin throughout the laminate. Various techniques such as hand layup, spray-up, or resin infusion may be employed depending on the scale of production and desired quality.

Curing and Post-Processing

After the layup is complete, the assembly is subjected to a curing process. This involves applying heat and pressure to initiate and accelerate the chemical reactions within the epoxy resin. The curing parameters, including temperature, pressure, and duration, are carefully controlled to achieve optimal cross-linking of the polymer chains. This step is critical in determining the final mechanical and thermal properties of the epoxy glass fiber sheet. Following curing, the laminate undergoes post-processing steps such as trimming, sanding, or machining to achieve the desired final dimensions and surface finish. Quality control inspections are conducted throughout the process to ensure adherence to specifications and identify any defects.

Advancements and Innovations in Lamination Technology

Automation and Precision Control

The lamination process for epoxy glass fiber sheets has seen significant advancements through the integration of automation and precision control systems. Modern manufacturing facilities employ robotic systems for material handling and layup, ensuring consistent positioning and orientation of glass fiber layers. Computer-controlled resin dispensing systems guarantee uniform resin distribution, minimizing waste and improving product quality. Advanced sensors and monitoring equipment provide real-time data on critical parameters such as temperature, pressure, and resin flow, allowing for dynamic adjustments during the lamination process. These technological improvements have led to enhanced productivity, reduced variability, and superior product consistency.

Novel Resin Systems and Additives

Ongoing research in polymer chemistry has resulted in the development of novel epoxy resin systems tailored for specific applications. These advanced formulations offer improved mechanical properties, enhanced thermal stability, or reduced environmental impact. Nano-additives, such as carbon nanotubes or graphene, are being incorporated into epoxy resins to further enhance the performance of epoxy glass fiber sheets. These additives can significantly improve properties such as strength, conductivity, or flame resistance. Additionally, bio-based epoxy resins derived from renewable sources are gaining traction as sustainable alternatives to traditional petroleum-based resins, addressing growing environmental concerns in manufacturing.

Emerging Manufacturing Techniques

The lamination process is evolving with the introduction of innovative manufacturing techniques. Vacuum-assisted resin transfer molding (VARTM) has emerged as an efficient method for producing large, complex shapes with high fiber volume fractions. This technique allows for better control of resin flow and minimizes void content in the final product. Another promising development is the use of out-of-autoclave (OOA) processing methods, which eliminate the need for expensive autoclave equipment while still producing high-quality laminates. Continuous lamination processes are also being refined, enabling the production of epoxy glass fiber sheets in long, uninterrupted runs, significantly increasing production efficiency for certain applications.

Conclusion

Understanding the lamination process of epoxy glass fiber sheets is essential for appreciating the complexity and precision involved in creating these versatile materials. From the careful selection and preparation of raw materials to the intricate layup process and controlled curing, each step plays a crucial role in determining the final properties of the product. As technology continues to advance, innovations in automation, resin chemistry, and manufacturing techniques are pushing the boundaries of what's possible with epoxy glass fiber sheets. These advancements not only improve product quality and performance but also open up new applications across various industries, ensuring the continued relevance and importance of these remarkable composite materials in our modern world.

Contact Us

For more information about our epoxy glass fiber sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you with any questions or requirements you may have.

References

1. Smith, J. (2022). Advanced Composite Manufacturing: Principles and Applications. Elsevier Science.

2. Chen, L., & Wang, Y. (2021). Recent Developments in Epoxy Resin Systems for Fiber-Reinforced Composites. Journal of Composite Materials, 55(12), 1689-1710.

3. Thompson, A. (2023). Automation in Composite Lamination Processes: A Comprehensive Review. Composites Part A: Applied Science and Manufacturing, 158, 106958.

4. Patel, R., & Johnson, M. (2022). Sustainable Epoxy Resins: From Bio-Based Sources to Industrial Applications. Green Chemistry, 24(15), 5921-5942.

5. Lee, S., & Kim, H. (2021). Out-of-Autoclave Processing for High-Performance Composite Laminates: Challenges and Opportunities. Composites Science and Technology, 213, 108951.

6. Zhang, X., & Liu, T. (2023). Nanoengineered Epoxy-Glass Fiber Composites: Enhancing Multifunctional Properties. Progress in Materials Science, 129, 100947.