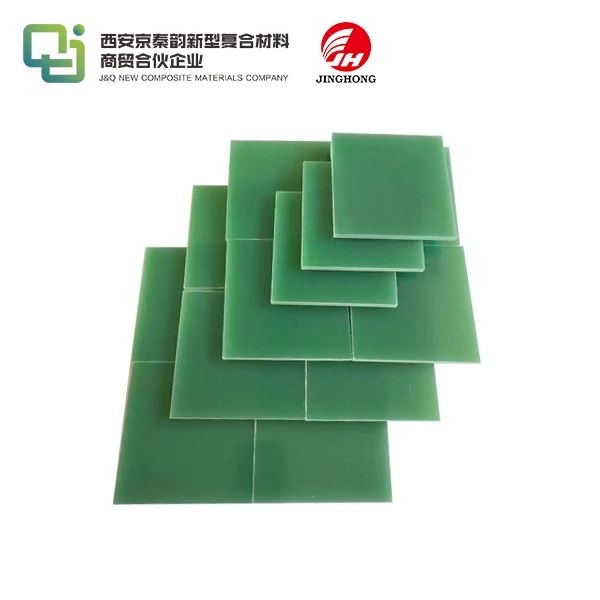

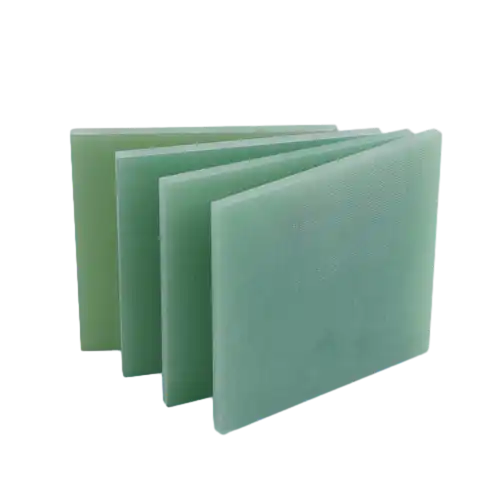

Is G10 FR4 the Best Material for PCBs?

2025-06-13 17:00:33

G10 FR4 sheet is widely considered the best material for Printed Circuit Boards (PCBs) due to its exceptional combination of electrical, mechanical, and thermal properties. This versatile laminate offers excellent insulation, dimensional stability, and flame resistance, making it ideal for a wide range of electronic applications. While alternatives exist, G10 FR4 sheet's balanced performance, cost-effectiveness, and reliability have solidified its position as the industry standard. However, the "best" material ultimately depends on specific project requirements, as some specialized applications may benefit from other materials with unique characteristics. Nonetheless, for most PCB designs, G10 FR4 sheet remains the top choice, providing a robust foundation for electronic devices across various sectors.

Understanding G10 FR4 Sheet Properties

Electrical Characteristics of G10 FR4

G10 FR4 sheet exhibits remarkable electrical properties that contribute to its widespread use in PCB manufacturing. The material boasts a high dielectric strength, typically ranging from 20 to 80 kV/mm, which ensures excellent insulation between conductive layers. This characteristic is crucial for preventing short circuits and maintaining signal integrity in complex circuit designs. Additionally, G10 FR4 demonstrates low dielectric loss, with a dissipation factor of approximately 0.02 at 1 MHz, minimizing energy dissipation in high-frequency applications. The material's volume resistivity, often exceeding 10^9 ohm-cm, further enhances its insulating capabilities, making it suitable for a diverse array of electronic devices.

Mechanical Strength and Durability

The mechanical robustness of G10 FR4 sheet is a key factor in its popularity for PCB fabrication. With a flexural strength ranging from 340 to 560 MPa, the material can withstand significant bending forces without compromising its structural integrity. This resilience is particularly valuable in applications subject to mechanical stress or vibration. G10 FR4 also exhibits impressive tensile strength, typically between 310 and 480 MPa, ensuring that PCBs can endure the rigors of assembly processes and operational conditions. The material's low water absorption rate, usually less than 0.1%, contributes to its dimensional stability and helps maintain consistent performance in varying environmental conditions.

Thermal Performance and Flame Resistance

G10 FR4 sheet demonstrates excellent thermal characteristics, making it suitable for a wide range of operating temperatures. The material maintains its properties from -65°C to 130°C, with a glass transition temperature (Tg) of approximately 130-140°C. This thermal stability ensures reliable performance across diverse environmental conditions. Moreover, the "FR" in FR4 stands for "Flame Retardant," indicating the material's ability to self-extinguish when exposed to flame. This fire-resistant property is critical for meeting safety standards in electronic devices. G10 FR4's thermal conductivity, typically around 0.29 W/mK, allows for efficient heat dissipation, which is essential for managing thermal loads in modern electronic circuits.

Comparing G10 FR4 to Alternative PCB Materials

G10 FR4 vs. FR-2 (Phenolic Resin)

When comparing G10 FR4 sheet to FR-2, also known as phenolic resin, several key differences emerge. FR-2 is generally less expensive and easier to machine than G10 FR4 sheet, making it suitable for simpler, low-cost applications. However, FR-2 exhibits inferior electrical properties, with a lower dielectric strength and higher moisture absorption rate. This makes FR-2 less suitable for high-frequency or high-reliability applications. G10 FR4 sheet's superior mechanical strength and thermal stability give it a significant advantage in more demanding environments. While FR-2 may be adequate for basic consumer electronics, G10 FR4 sheet remains the preferred choice for professional-grade PCBs that require consistent performance and longevity.

G10 FR4 vs. Polyimide

Polyimide is another material used in PCB manufacturing, particularly in high-temperature applications. Compared to G10 FR4 sheet, polyimide offers superior thermal resistance, maintaining its properties at temperatures up to 260°C. This makes polyimide ideal for aerospace, military, and other extreme-environment applications. However, polyimide is significantly more expensive than G10 FR4 sheet and can be more challenging to process. G10 FR4 sheet provides a more cost-effective solution for the majority of PCB applications, offering a balanced combination of electrical, mechanical, and thermal properties that meet the needs of most designs. Unless extreme temperature resistance is required, G10 FR4 sheet remains the more practical and economical choice for most PCB manufacturers.

G10 FR4 vs. High-Frequency Laminates

High-frequency laminates, such as Rogers RO4350B or Taconic RF-35, are specifically designed for applications operating at frequencies above 500 MHz. These materials offer lower dielectric constants and loss tangents compared to G10 FR4 sheet, resulting in improved signal integrity and reduced signal loss at high frequencies. However, high-frequency laminates are considerably more expensive than G10 FR4 sheet and may require specialized processing techniques. For most applications below 500 MHz, G10 FR4 sheet provides adequate performance at a fraction of the cost. The widespread availability and familiarity of G10 FR4 sheet in the industry also contribute to its continued popularity, even as high-frequency applications become more common.

Optimizing G10 FR4 Usage in PCB Design

Selecting Appropriate G10 FR4 Grades

G10 FR4 sheet is available in various grades, each tailored to specific application requirements. Standard G10 FR4 sheet is suitable for most general-purpose PCBs, offering a balanced set of properties. For high-temperature applications, high-Tg variants of G10 FR4 sheet are available, featuring glass transition temperatures up to 180°C. These grades provide enhanced thermal stability and reliability in demanding environments. Halogen-free G10 FR4 sheet options are also available for environmentally conscious designs, meeting strict regulatory requirements without compromising performance. When selecting a G10 FR4 sheet grade, designers should consider factors such as operating temperature, environmental conditions, and regulatory compliance to ensure optimal performance and longevity of the final product.

Optimizing Layer Stack-up for G10 FR4 PCBs

Effective layer stack-up design is crucial for maximizing the benefits of G10 FR4 sheet in multilayer PCBs. By carefully planning the arrangement of signal, power, and ground layers, designers can optimize signal integrity and minimize electromagnetic interference. Alternating signal and ground layers can help reduce crosstalk and improve overall board performance. The thickness of G10 FR4 sheet layers can be adjusted to control impedance and manage thermal dissipation. For high-speed designs, techniques such as stripline routing and controlled impedance traces can be implemented to maintain signal quality. By leveraging G10 FR4 sheet's consistent dielectric properties, designers can create reliable and predictable PCB stack-ups that meet the demands of modern electronic systems.

Manufacturing Considerations for G10 FR4 PCBs

While G10 FR4 is generally easy to work with, certain manufacturing considerations can help optimize PCB production. Proper handling and storage of G10 FR4 sheets are essential to prevent moisture absorption and maintain dimensional stability. During the drilling process, using appropriate feed rates and spindle speeds can minimize delamination and ensure clean hole walls. For high-aspect-ratio vias, special attention should be given to plating processes to ensure reliable connections. In multilayer PCB fabrication, controlling prepreg flow and lamination parameters is crucial for achieving consistent layer-to-layer registration. By adhering to best practices in G10 FR4 PCB manufacturing, producers can maximize yield and ensure the quality and reliability of the final product.

Conclusion

G10 FR4 sheet has earned its reputation as the premier material for PCB manufacturing through its exceptional blend of electrical, mechanical, and thermal properties. While alternatives may offer advantages in specific niche applications, G10 FR4's versatility, cost-effectiveness, and proven track record make it the optimal choice for the vast majority of PCB designs. By understanding the material's characteristics and optimizing its usage in PCB design and manufacturing processes, engineers can fully leverage G10 FR4's capabilities to create high-performance, reliable electronic systems across a wide range of industries and applications.

Contact Us

For more information about G10 FR4 sheet and how it can benefit your PCB projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right materials and optimizing your PCB designs for success.

References

1. Johnson, R. W., & Terlep, J. A. (2019). Printed Circuit Board Materials Handbook. CRC Press.

2. Smith, L. D., & Bogatin, E. (2020). Principles of Power Integrity for PDN Design. Artech House.

3. Coombs, C. F. (2018). Printed Circuits Handbook. McGraw-Hill Education.

4. Ritchey, L. W., & Zasio, J. J. (2017). Right the First Time: A Practical Handbook on High-Speed PCB and System Design. Speeding Edge.

5. Ulrich, R. K., & Brown, W. D. (2021). Advanced Electronic Packaging. Wiley-IEEE Press.

6. Hall, S. H., & Heck, H. L. (2019). Advanced Signal Integrity for High-Speed Digital Designs. Wiley-IEEE Press.

_1732777843529.webp)