Understanding NEMA Grades for Phenolic Cotton Laminated Sheets

2025-06-23 16:20:37

NEMA grades for phenolic cotton laminated sheets are standardized classifications that define the physical, electrical, and mechanical properties of these versatile materials. These grades, established by the National Electrical Manufacturers Association (NEMA), provide a reliable framework for selecting the appropriate phenolic cotton laminated sheet for specific applications. Understanding these grades is crucial for engineers, manufacturers, and procurement specialists working with electrical insulation and mechanical components. Each NEMA grade, such as the widely used phenolic cotton cloth laminate sheet 3026, offers unique characteristics tailored to different industrial requirements, ensuring optimal performance and safety in various environments.

Introduction to Phenolic Cotton Laminated Sheets

Composition and Manufacturing Process

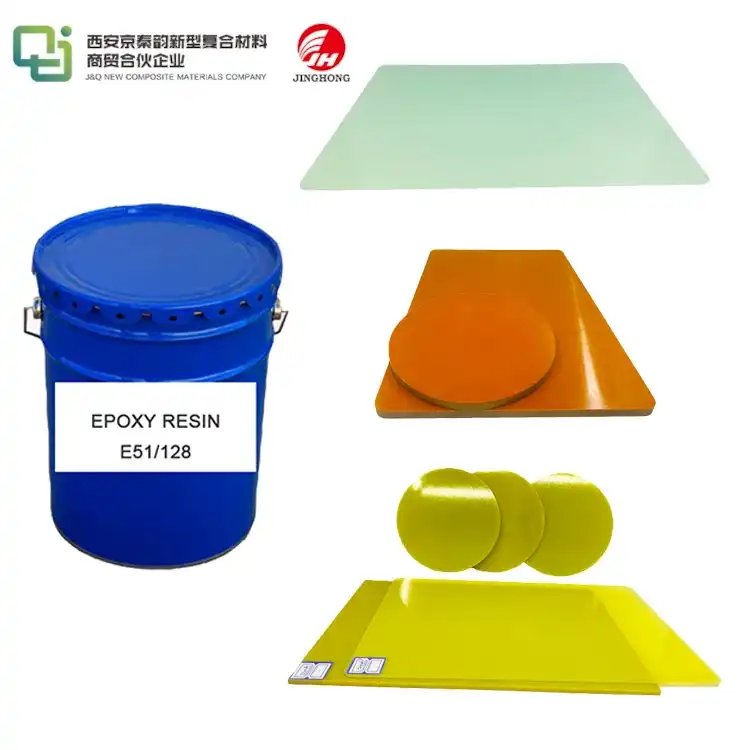

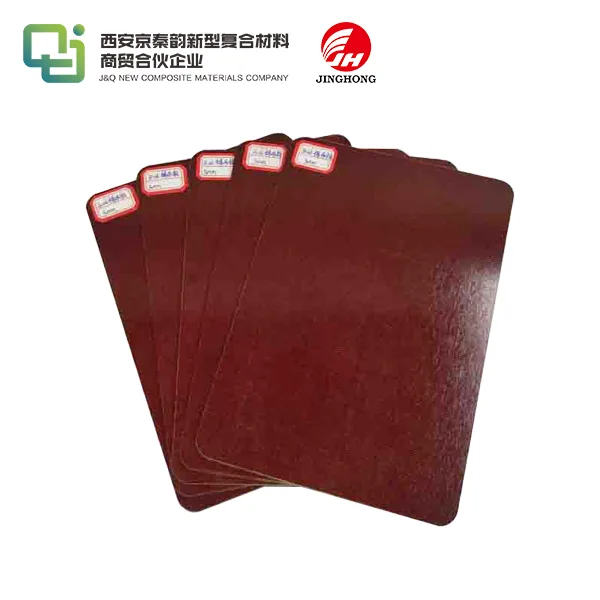

Phenolic cotton laminated sheets are composite materials crafted from layers of cotton fabric impregnated with phenolic resin. The manufacturing process involves carefully layering the resin-soaked cotton sheets and subjecting them to high pressure and temperature. This process results in a dense, uniform material with exceptional electrical insulation properties and mechanical strength.

Key Properties and Applications

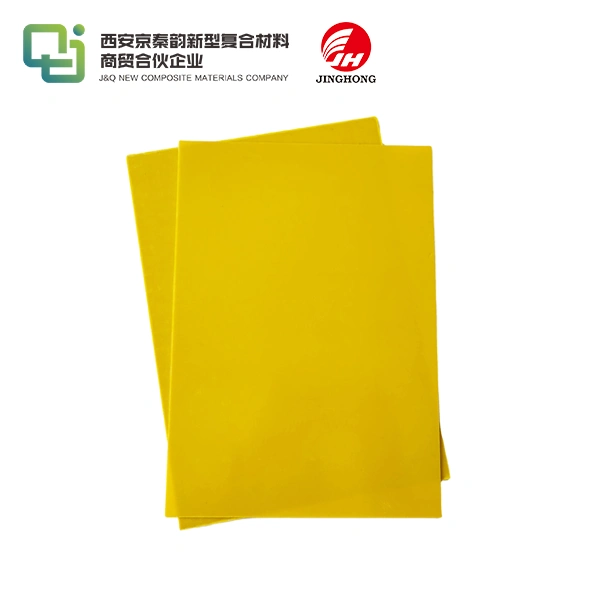

These sheets boast an impressive array of properties, including high dielectric strength, low moisture absorption, and excellent dimensional stability. Their versatility makes them indispensable in various industries, from electrical equipment to aerospace. The phenolic cotton cloth laminate sheet 3026, for instance, is renowned for its balance of electrical and mechanical properties, making it a popular choice for switchgear components and industrial machinery.

Importance of NEMA Grading System

The NEMA grading system plays a pivotal role in standardizing phenolic cotton laminated sheets. It provides a universal language for manufacturers and users to communicate product specifications effectively. By adhering to these grades, industries can ensure consistency in quality and performance across different suppliers and applications.

Detailed Analysis of NEMA Grades

NEMA Grade X

NEMA Grade X is considered the standard entry-level option for phenolic cotton laminated sheets. It provides satisfactory electrical insulation and moderate mechanical strength, making it suitable for basic industrial and electrical applications. Although it is not designed for high-stress or extreme environments, it performs reliably in low-voltage settings. Typical uses include insulating bushings, terminal boards, and low-voltage switchgear panels. Its affordability and ease of machining make Grade X a practical choice for manufacturers prioritizing cost efficiency and functional performance in controlled conditions.

NEMA Grade CE

NEMA Grade CE offers an upgrade over Grade X, featuring improved mechanical strength, impact resistance, and machinability. This makes it a popular choice in applications that demand both structural integrity and reliable insulation. It is commonly used in motor components, terminal boards, and transformer parts where parts may face mechanical loads. The phenolic cotton cloth laminate sheet 3026 is a representative material within this grade. With its enhanced durability and processing flexibility, Grade CE bridges the gap between basic utility and higher-performance requirements.

NEMA Grade LE

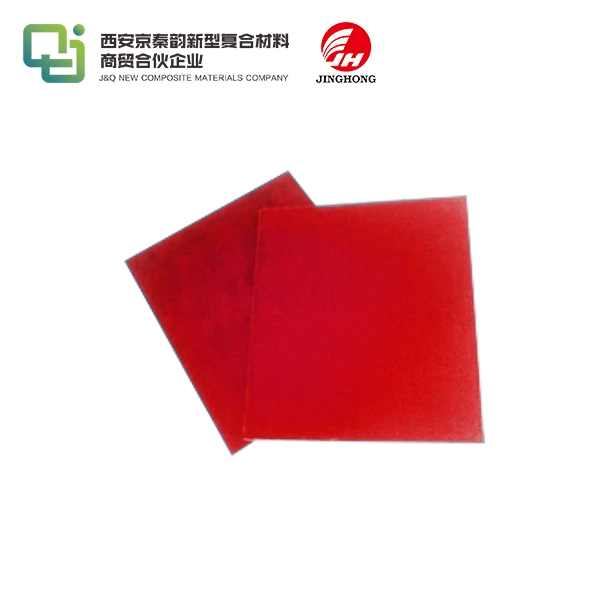

NEMA Grade LE stands out for its superior electrical insulation, arc resistance, and tracking resistance, especially in high-voltage environments. This grade uses fine linen fabric reinforcement, giving it excellent machining precision and surface finish. LE-grade phenolic cotton laminated sheets are ideal for high-performance electrical systems, such as switchgear assemblies, circuit breakers, and control equipment subjected to harsh operating conditions. The combination of fine electrical properties and reliable mechanical strength makes Grade LE essential for advanced industrial applications requiring both precision and resilience.

Selecting the Right NEMA Grade for Your Application

Assessing Environmental Factors

When selecting a phenolic cotton laminated sheet, carefully evaluating environmental conditions is essential to ensure long-term reliability and material integrity. Variables such as ambient temperature, relative humidity, and chemical exposure directly influence the sheet’s performance. For instance, environments with persistent moisture or fluctuating humidity levels demand materials with enhanced water resistance. In such cases, phenolic cotton cloth laminate sheet 3026 offers superior resistance to moisture absorption, making it a reliable choice. Matching the material's properties to environmental challenges helps prevent degradation and mechanical failure.

Evaluating Mechanical Requirements

The mechanical stresses your application may encounter should heavily influence your choice of NEMA grade. Considerations include static and dynamic loads, potential impacts, and the need for shape retention under pressure or heat. Phenolic cotton laminated sheets like Grade CE or Grade LE are well-suited for applications that demand high mechanical strength and wear resistance. These grades provide improved durability and dimensional stability compared to basic Grade X, which may deform or fracture under intensive use. A tailored mechanical profile ensures operational safety and longevity.

Analyzing Electrical Specifications

Electrical performance is often a top priority when selecting phenolic cotton laminated sheets for industrial or electronic applications. Key properties to evaluate include dielectric strength, arc resistance, and insulation reliability under voltage stress. For systems requiring robust electrical insulation in high-voltage conditions, Grade LE offers enhanced electrical characteristics. In contrast, Grade CE or Grade X may suffice for moderate or low-voltage setups. Ensuring the correct electrical rating minimizes the risk of short circuits, electrical failure, or system inefficiencies in the application environment.

Conclusion

Understanding NEMA grades for phenolic cotton laminated sheets is essential for making informed decisions in electrical and mechanical engineering applications. These grades provide a standardized framework that ensures consistency and reliability across different manufacturers and applications. By carefully considering the environmental, mechanical, and electrical requirements of your project, you can select the optimal grade, such as the versatile phenolic cotton cloth laminate sheet 3026, to meet your specific needs. This knowledge empowers engineers and procurement specialists to make choices that enhance product performance, safety, and longevity.

Contact Us

For more information about our range of phenolic cotton laminated sheets and expert guidance on selecting the right grade for your application, please contact us at info@jhd-material.com. Our team of experienced professionals is ready to assist you in finding the perfect solution for your industrial needs.

References

1. National Electrical Manufacturers Association. (2021). "NEMA LI 1: Industrial Laminated Thermosetting Products."

2. IEEE. (2020). "Standard for Test Procedures and Requirements for Electrical Insulating Materials."

3. Smith, J.R. (2019). "Phenolic Resins: A Century of Progress." Springer Science & Business Media.

4. Johnson, A.L. (2018). "Advances in Composite Materials for Electrical Insulation." Elsevier.

5. American Society for Testing and Materials. (2022). "ASTM D709: Standard Specification for Laminated Thermosetting Materials."

6. International Electrotechnical Commission. (2021). "IEC 60893-3-2: Specification for Industrial Rigid Laminated Sheets Based on Thermosetting Resins for Electrical Purposes."