What Are the Key Properties of Phenolic Cotton Laminate?

2025-06-25 17:02:45

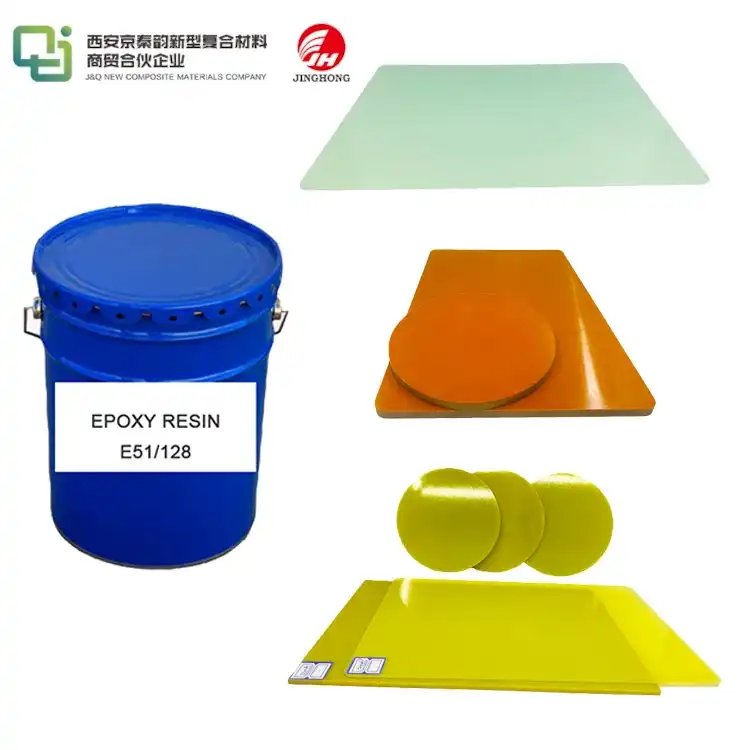

When exploring the realm of insulating materials, phenolic cotton laminate stands out as a versatile and robust option. This material, often referred to as phenolic cotton laminated sheet, boasts a unique blend of attributes that make it indispensable across various industries. Its key properties include exceptional mechanical strength, remarkable electrical insulation, and impressive resistance to heat and chemicals. Additionally, it offers low moisture absorption, ensuring durability in humid environments, and exhibits commendable dimensional stability under stress. These characteristics position phenolic cotton laminate as a preferred choice for manufacturers seeking reliable insulation solutions globally. Curious to delve deeper into why this material excels? Let's unpack its properties, applications, and advantages in detail.

Unveiling the Core Characteristics of Phenolic Cotton Laminate

Mechanical Fortitude: Strength That Endures

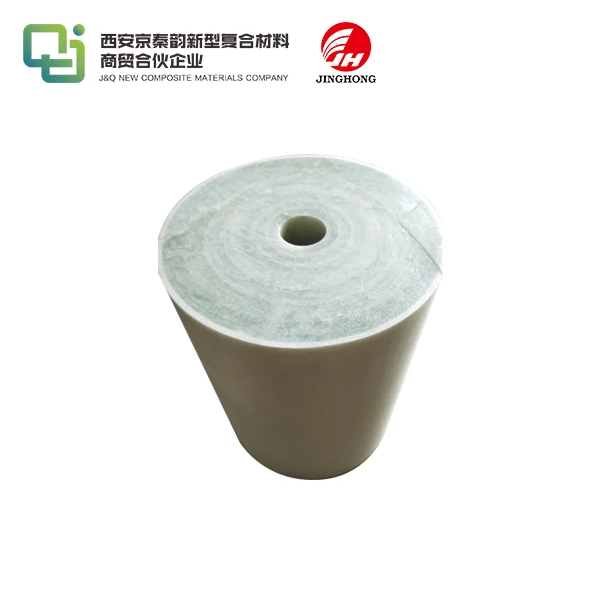

One of the standout traits of phenolic cotton laminated sheet lies in its mechanical prowess. This material is engineered by impregnating layers of cotton fabric with phenolic resin, creating a composite that withstands significant physical stress. Its tensile and compressive strength make it ideal for applications requiring load-bearing capabilities, such as gears, bearings, and structural components. Unlike many synthetic alternatives, this laminate retains its integrity even under prolonged mechanical strain, offering manufacturers a dependable solution for demanding environments. The interwoven cotton fibers enhance its toughness, ensuring it resists wear and tear over extended periods, a feature that proves invaluable in industrial settings.

Electrical Insulation: A Barrier Against Conductivity

Another hallmark of phenolic cotton laminate is its superior electrical insulating capacity. This property stems from the non-conductive nature of both the phenolic resin and the cotton substrate, making it an excellent choice for electrical enclosures, switchgear, and circuit breaker components. The material's ability to prevent unwanted electrical currents ensures safety and reliability in high-voltage applications. Manufacturers across the globe rely on this laminate to safeguard equipment and personnel, particularly in sectors where electrical faults could lead to catastrophic consequences. Its consistent dielectric performance, even in fluctuating conditions, underscores its role as a cornerstone in electrical engineering.

Thermal and Chemical Resilience: Defying Harsh Environments

Phenolic cotton laminated sheet excels in environments where heat and corrosive substances are prevalent. With a thermal endurance that allows it to operate effectively at temperatures up to 120°C, this material is well-suited for applications involving moderate heat exposure. Beyond thermal stability, its resistance to chemicals, including oils, solvents, and acids, enhances its longevity in aggressive industrial settings. This resilience minimizes degradation, ensuring that components crafted from this laminate maintain their functionality over time. Manufacturers value this adaptability, as it reduces maintenance costs and extends the service life of their products, particularly in challenging operational contexts.

Applications That Showcase Phenolic Cotton Laminate's Versatility

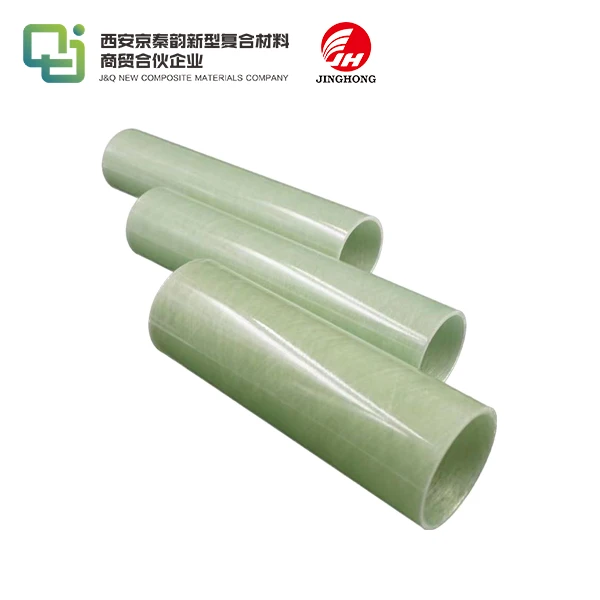

Industrial Machinery: Powering Performance

The robust nature of phenolic cotton laminate makes it a linchpin in the realm of industrial machinery. Its mechanical strength and wear resistance are harnessed in the production of gears, rollers, and bushings, where precision and durability are paramount. These components often endure continuous friction and heavy loads, conditions under which this laminate thrives. Its low friction coefficient further enhances its suitability for moving parts, reducing energy loss and improving operational efficiency. Manufacturers globally turn to this material to craft machinery parts that deliver consistent performance, highlighting its role as a cornerstone in industrial innovation.

Electrical Systems: Ensuring Safety and Reliability

In the domain of electrical systems, phenolic cotton laminated sheet proves its mettle as an insulating stalwart. Its dielectric properties are leveraged in the construction of terminal boards, insulating washers, and transformer spacers, where preventing electrical arcing is critical. The material's ability to maintain its insulating capabilities under varying humidity levels adds to its appeal, particularly in regions with diverse climates. By incorporating this laminate into their designs, manufacturers enhance the safety and longevity of electrical systems, catering to industries ranging from telecommunications to power generation, where reliability is non-negotiable.

Automotive Engineering: Driving Innovation

The automotive sector also reaps the benefits of phenolic cotton laminate's multifaceted properties. Its thermal stability and chemical resistance make it an ideal candidate for under-the-hood components, such as insulating pads and mounting brackets, which are exposed to heat and automotive fluids. Additionally, its dimensional stability ensures that parts retain their shape under mechanical stress, a crucial factor in high-performance vehicles. This laminate's lightweight yet sturdy composition aligns with the industry's push toward efficiency and sustainability, enabling manufacturers to design vehicles that are both durable and fuel-efficient, meeting the demands of a global market.

Advantages That Set Phenolic Cotton Laminate Apart

Cost-Effectiveness: Balancing Quality and Affordability

One of the compelling advantages of phenolic cotton laminated sheet is its cost-effectiveness. While offering a suite of high-performance properties, this material remains competitively priced compared to alternatives like glass-reinforced laminates or advanced polymers. This balance between quality and affordability appeals to manufacturers seeking to optimize production costs without compromising on reliability. The laminate's longevity further enhances its economic value, as components require less frequent replacement, reducing downtime and maintenance expenses. This attribute is particularly beneficial for global manufacturers aiming to deliver value-driven solutions across diverse markets.

Environmental Adaptability: Thriving in Diverse Conditions

Phenolic cotton laminate's ability to perform across a spectrum of environmental conditions is another feather in its cap. Its low moisture absorption ensures that it remains stable in humid or wet environments, preventing swelling or degradation that could impair functionality. This property is especially advantageous in tropical or coastal regions, where humidity levels can challenge material performance. Coupled with its thermal and chemical resilience, this adaptability makes the laminate a versatile choice for manufacturers operating in varied climates, ensuring consistent product quality regardless of geographic location.

Ease of Fabrication: Streamlining Manufacturing Processes

The practicality of working with phenolic cotton laminated sheet cannot be overstated. Its composition allows for straightforward machining, cutting, and shaping, enabling manufacturers to craft intricate components with precision. This ease of fabrication reduces production time and costs, making it an attractive option for both large-scale and bespoke manufacturing projects. The material's uniform structure minimizes the risk of defects during processing, ensuring that finished products meet stringent quality standards. This advantage is particularly significant for manufacturers aiming to maintain efficiency and scalability in their operations, reinforcing the laminate's status as a go-to material in industrial applications.

Conclusion

Phenolic cotton laminate emerges as a material of choice for manufacturers worldwide, thanks to its blend of mechanical strength, electrical insulation, and environmental resilience. Its versatility shines through in applications spanning industrial machinery, electrical systems, and automotive engineering, while its cost-effectiveness and adaptability enhance its appeal. By leveraging these properties, manufacturers can create durable, reliable products that meet the demands of diverse global markets. This laminate's ability to balance performance with practicality underscores its enduring relevance in the realm of insulating materials.

Contact Us

Ready to explore how phenolic cotton laminate sheet can elevate your manufacturing projects? With over 20 years of expertise in producing insulating sheets and a decade of experience in global trade, J&Q is here to provide tailored solutions. Contact us today at info@jhd-material.com for more information.

References

1. Smith, J. A. (2019). Composite Materials in Industrial Applications: Properties and Performance. New York: Engineering Press.

2. Patel, R. K. (2021). Electrical Insulation Materials: Design and Applications. London: Technical Publications.

3. Nguyen, T. H. (2020). Thermal and Chemical Resistance in Laminates: A Comprehensive Study. Chicago: Industrial Materials Institute.

4. Kumar, S. (2018). Mechanical Properties of Phenolic-Based Composites. Boston: Academic Publishers.

5. Lee, M. S. (2022). Advancements in Insulating Materials for Automotive Engineering. Tokyo: Innovation Press.

6. Brown, E. L. (2017). Fabrication Techniques for Industrial Laminates. Sydney: Manufacturing Insights.