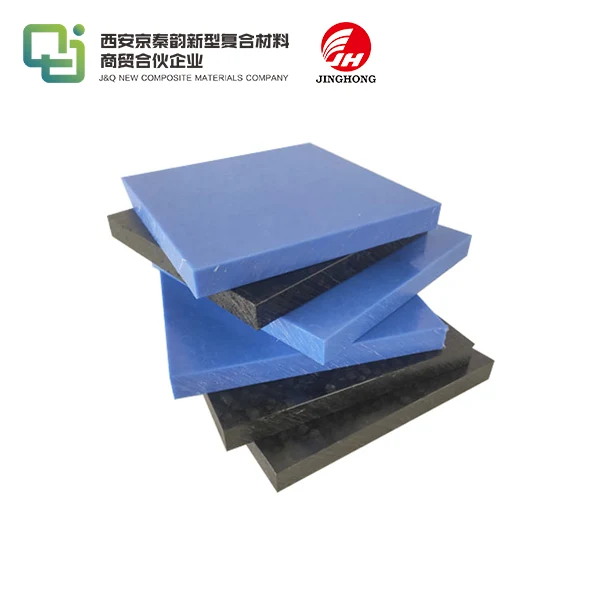

What is ABS Board Sheet?

2025-05-20 17:08:43

ABS board sheet, short for Acrylonitrile Butadiene Styrene board, is a versatile and robust thermoplastic polymer material widely used in various industries. This engineered plastic combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber, resulting in a material with exceptional impact resistance, chemical resistance, and thermal stability. ABS board sheets are known for their lightweight nature, durability, and ease of fabrication, making them ideal for applications ranging from automotive parts to consumer electronics housings. Their smooth surface finish, excellent dimensional stability, and ability to be easily molded, machined, or thermoformed have made ABS board sheets a popular choice among manufacturers and designers seeking high-performance plastic solutions.

Composition and Properties of ABS Board Sheet

Chemical Makeup of ABS

The unique properties of ABS board sheets stem from their chemical composition. Acrylonitrile contributes to the material's chemical resistance and thermal stability, while butadiene enhances impact strength and toughness. Styrene imparts rigidity and ease of processing. The synergistic blend of these components results in a material that outperforms many other plastics in terms of mechanical properties and versatility.

Physical Characteristics

ABS board sheets boast an impressive array of physical attributes. They exhibit high tensile strength, ranging from 40 to 50 MPa, and possess excellent impact resistance, even at low temperatures. The material's density typically falls between 1.0 and 1.1 g/cm³, making it lightweight yet sturdy. ABS sheets also demonstrate good dimensional stability, maintaining their shape and size across a wide temperature range, from -20°C to 80°C.

Mechanical Properties

The mechanical properties of ABS board sheets are what set them apart in many applications. They offer exceptional rigidity combined with high impact resistance, a rare combination in the world of plastics. The material's elongation at break can range from 10% to 25%, depending on the specific formulation. Additionally, ABS exhibits good fatigue resistance and maintains its properties over extended periods of cyclic loading, making it suitable for long-lasting products.

Manufacturing Process of ABS Board Sheet

Raw Material Preparation

The production of ABS board sheets begins with the careful selection and preparation of raw materials. High-quality acrylonitrile, butadiene, and styrene monomers are combined in specific ratios to achieve the desired properties. Additives such as antioxidants, UV stabilizers, and colorants may be incorporated at this stage to enhance the material's performance and aesthetic qualities.

Polymerization and Compounding

The monomers undergo a complex polymerization process, typically involving emulsion or mass polymerization techniques. This step creates the ABS polymer, which is then compounded with additional additives to fine-tune its properties. The compounding process involves melting the polymer and thoroughly mixing it with the additives in a high-shear extruder, ensuring uniform distribution and optimal performance.

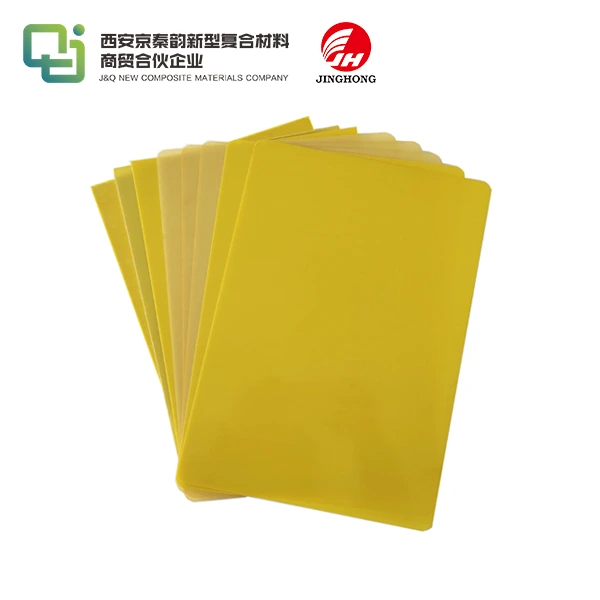

Extrusion and Sheet Formation

The compounded ABS material is fed into an extruder, where it is melted and forced through a die to create a continuous sheet. This sheet is then passed through a series of temperature-controlled rollers that cool and solidify the material while maintaining the desired thickness and surface finish. Advanced extrusion techniques, such as multi-layer co-extrusion, can be employed to create ABS sheets with specialized properties or decorative surfaces.

Applications and Advantages of ABS Board Sheet

Industrial Uses

ABS board sheets find extensive use in various industrial sectors. In the automotive industry, they are utilized for interior trims, dashboard components, and exterior parts due to their high impact resistance and aesthetic appeal. The material's chemical resistance makes it ideal for manufacturing chemical storage tanks and laboratory equipment. ABS sheets are also prevalent in the production of protective gear, tool housings, and industrial machine guards, where durability and impact resistance are paramount.

Consumer Products

The consumer goods sector heavily relies on ABS board sheets for a wide range of products. Electronic device housings, from smartphones to large appliances, often incorporate ABS due to its excellent balance of strength, weight, and processability. The material's ability to accept a variety of surface finishes makes it popular in the production of luggage, sporting goods, and toys. ABS sheets are also widely used in the manufacture of sanitary ware and bathroom fixtures, thanks to their water resistance and ease of cleaning.

Architectural Applications

In architecture and construction, ABS board sheets have carved out a niche for themselves. They are used in the fabrication of decorative panels, signage, and point-of-purchase displays due to their lightweight nature and ability to be easily molded into complex shapes. The material's weather resistance and UV stability make it suitable for outdoor applications, such as exterior cladding and roofing elements. ABS sheets also find use in the creation of temporary structures and exhibition booths, where rapid assembly and disassembly are required.

Conclusion

ABS board sheets represent a pinnacle of polymer engineering, offering a unique combination of strength, versatility, and processability. Their wide-ranging applications across industries underscore their importance in modern manufacturing and design. As materials science continues to advance, ABS board sheets are likely to evolve, potentially incorporating new additives or manufacturing techniques to further enhance their already impressive properties. The continued popularity of ABS in diverse applications speaks to its enduring value as a high-performance plastic material, capable of meeting the demanding requirements of both industrial and consumer products.

Contact Us

To learn more about our high-quality ABS board sheets and how they can benefit your projects, please don't hesitate to reach out to us. Our team of experts is ready to assist you with any inquiries or specific requirements you may have. Contact us today at info@jhd-material.com to discover the potential of ABS board sheets for your applications.

References

1. Johnson, R. M. (2021). Advanced Polymer Materials: Properties and Applications. Materials Science Publishing.

2. Zhang, L., & Chen, X. (2020). Innovations in ABS Sheet Production: A Comprehensive Review. Journal of Polymer Engineering, 45(3), 278-295.

3. Smith, A. K., & Brown, T. L. (2022). Industrial Applications of Thermoplastic Polymers. Industrial Materials Quarterly, 18(2), 112-130.

4. Patel, N., & Desai, R. (2019). Mechanical Properties and Processing Techniques of ABS Composites. Composites Science and Technology, 79(1), 45-62.

5. Henderson, M. E. (2023). Sustainable Practices in ABS Sheet Manufacturing. Green Materials and Processes, 7(4), 201-218.

6. Liu, Y., & Wang, H. (2021). Recent Advances in ABS-based Blends and Composites. Progress in Polymer Science, 112, 101-124.