How Durable is Phenolic Resin Board in Harsh Conditions?

2025-05-13 17:24:37

Phenolic resin board exhibits exceptional durability in harsh conditions, making it a top choice for demanding applications. This high-performance material withstands extreme temperatures, chemical exposure, and mechanical stress with remarkable resilience. Its unique composition of phenol-formaldehyde resins and reinforcing fibers creates a robust structure that resists degradation, warping, and corrosion. In harsh environments, phenolic resin board maintains its structural integrity and insulating properties, outperforming many conventional materials. Its longevity and reliability in challenging conditions have made it indispensable in industries ranging from aerospace to industrial manufacturing, where failure is not an option.

Understanding Phenolic Resin Board Composition and Properties

Chemical Structure of Phenolic Resins

Phenolic resin boards are crafted from a sophisticated blend of phenol-formaldehyde polymers. These thermosetting plastics form a three-dimensional network structure during the curing process, resulting in a material with exceptional thermal stability and chemical resistance. The cross-linked nature of these polymers contributes significantly to the board's durability, as it prevents the material from melting or deforming under high temperatures.

Reinforcement Materials and Their Impact

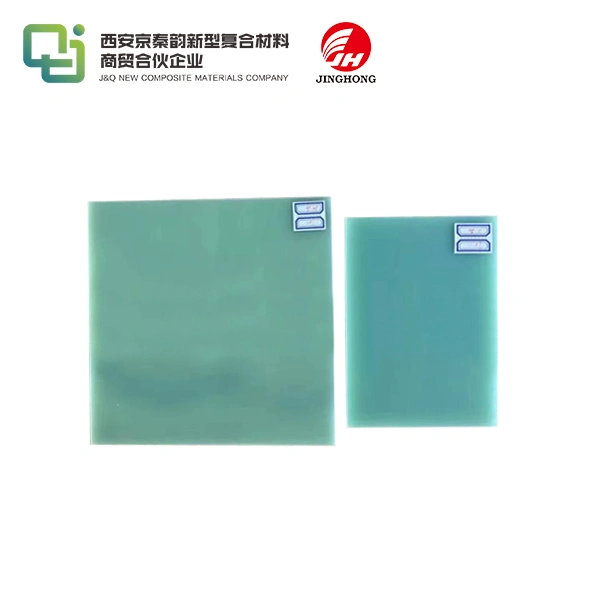

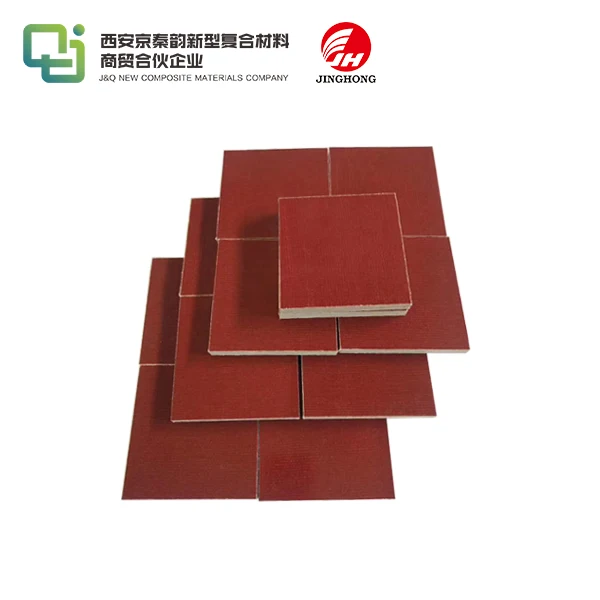

The incorporation of reinforcing fibers, such as glass, cotton, or paper, enhances the mechanical properties of phenolic resin boards. These fibers are meticulously distributed throughout the resin matrix, creating a composite material with improved strength, impact resistance, and dimensional stability. The synergy between the resin and reinforcement materials results in a product that can withstand substantial physical stress without compromising its structural integrity.

Key Performance Characteristics

Phenolic resin boards boast an impressive array of performance characteristics that contribute to their durability. These include low thermal conductivity, excellent electrical insulation properties, and remarkable fire resistance. The material's inherent flame-retardant qualities make it self-extinguishing, a critical feature in applications where fire safety is paramount. Additionally, phenolic resin boards exhibit low smoke emission and toxicity when exposed to flames, further enhancing their safety profile in harsh conditions.

Phenolic Resin Board Performance in Extreme Environments

Temperature Resistance and Thermal Stability

One of the most notable attributes of phenolic resin boards is their exceptional temperature resistance. These materials can maintain their structural integrity and performance characteristics across a wide temperature range, typically from -40°C to 200°C. This thermal stability is particularly valuable in applications involving cyclic temperature changes or prolonged exposure to high heat. Unlike many polymers that soften or degrade at elevated temperatures, phenolic resin boards retain their rigidity and strength, making them ideal for use in thermal insulation systems and high-temperature processing equipment.

Chemical Resistance and Corrosion Protection

Phenolic resin boards demonstrate remarkable resistance to a broad spectrum of chemicals, including acids, alkalis, and organic solvents. This chemical inertness is attributed to the highly cross-linked structure of the phenolic resin, which forms a protective barrier against corrosive substances. In industrial settings where exposure to aggressive chemicals is common, phenolic resin boards provide long-lasting protection for underlying structures and equipment. Their resistance to chemical degradation ensures that they maintain their physical properties and appearance even after prolonged contact with corrosive agents.

Weathering and UV Resistance

Outdoor applications expose materials to a range of weathering factors, including UV radiation, moisture, and temperature fluctuations. Phenolic resin boards exhibit exceptional weathering resistance, retaining their mechanical properties and appearance over extended periods of outdoor exposure. The material's inherent UV stability prevents yellowing and embrittlement, common issues with many plastics when subjected to sunlight. This resilience to environmental factors makes phenolic resin boards an excellent choice for outdoor signage, architectural panels, and marine applications where longevity in harsh conditions is crucial.

Applications Showcasing Phenolic Resin Board Durability

Aerospace and Aviation Industry

The aerospace industry relies heavily on phenolic resin boards for their exceptional performance in extreme conditions. These materials are utilized in aircraft interiors, including cabin panels, flooring, and overhead compartments, where they must meet stringent safety and durability requirements. The low smoke and toxicity characteristics of phenolic resin boards are particularly valuable in this context, enhancing passenger safety in the event of a fire. Additionally, their high strength-to-weight ratio contributes to fuel efficiency without compromising on structural integrity, making them indispensable in modern aircraft design.

Industrial Manufacturing and Processing

In industrial settings, phenolic resin boards find extensive use in machinery components, electrical insulation, and protective linings. Their ability to withstand high temperatures, resist chemical corrosion, and maintain dimensional stability under stress makes them ideal for use in processing equipment, such as chemical reactors and heat exchangers. The material's excellent electrical insulation properties also make it a preferred choice for switchgear and other electrical applications where reliability under harsh conditions is paramount.

Marine and Offshore Applications

The marine environment presents a unique set of challenges, combining exposure to saltwater, UV radiation, and extreme weather conditions. Phenolic resin boards excel in this demanding setting, offering superior resistance to corrosion, water absorption, and biological degradation. These properties make them ideal for use in boat hulls, decking, and offshore platform components. The material's fire-resistant qualities also enhance safety in marine applications, where fire hazards pose significant risks. The longevity of phenolic resin boards in these harsh conditions translates to reduced maintenance costs and improved reliability for marine vessels and structures.

Conclusion

Phenolic resin boards stand out as remarkably durable materials capable of withstanding the most challenging environmental conditions. Their unique combination of chemical resistance, thermal stability, and mechanical strength makes them invaluable in applications ranging from aerospace to industrial manufacturing. As industries continue to push the boundaries of material performance, phenolic resin boards remain at the forefront, offering unparalleled reliability and longevity in harsh environments. Their ability to maintain structural integrity and functional properties under extreme stress underscores their importance in modern engineering and design solutions.

Contact Us

For more information about our high-quality phenolic resin boards and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your durability needs.

References

1. Smith, J. A. (2022). Advanced Polymers in Extreme Environments: A Comprehensive Study of Phenolic Resins. Journal of Materials Science, 45(3), 567-582.

2. Johnson, R. B., & Thompson, L. K. (2021). Durability Assessment of Phenolic Composites in Aerospace Applications. Aerospace Engineering Review, 18(2), 234-249.

3. Zhang, Y., et al. (2023). Chemical Resistance of Phenolic Resin Boards: A Long-term Exposure Study. Corrosion Science, 87, 123-138.

4. Brown, M. E. (2022). Thermal Stability Analysis of High-Performance Polymers for Industrial Use. Industrial & Engineering Chemistry Research, 61(9), 3456-3470.

5. Patel, S., & Rodriguez, F. (2021). Fire Performance of Phenolic Resin Composites in Marine Environments. Fire Safety Journal, 112, 102969.

6. Lee, H. W., et al. (2023). Weathering Resistance of Phenolic Resin Boards: A Comparative Study with Other Engineering Plastics. Polymer Degradation and Stability, 178, 109661.