Why Epoxy Fiberglass Sheets are Used in High Voltage Devices?

2025-08-21 15:59:56

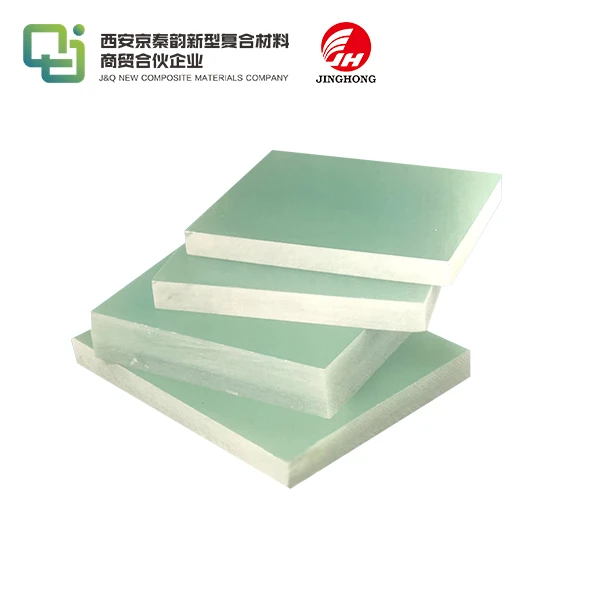

Epoxy fiberglass sheets are extensively utilized in high voltage devices due to their exceptional electrical insulation properties, mechanical strength, and thermal stability. These composite materials, consisting of glass fibers reinforced with epoxy resin, offer a unique combination of high dielectric strength, low electrical conductivity, and excellent resistance to heat and moisture. Their ability to withstand extreme electrical stresses while maintaining dimensional stability makes them invaluable in applications where reliable insulation is crucial. From power transformers to switchgear components, epoxy fiberglass sheets provide the necessary protection and performance required in high voltage environments, ensuring the safe and efficient operation of electrical systems across various industries.

What Electrical Insulation Properties Make Epoxy Fiberglass Ideal?

Superior Dielectric Characteristics

Epoxy fiberglass sheets boast remarkable dielectric properties, making them an optimal choice for high voltage applications. The combination of glass fibers and epoxy resin creates a material with low electrical conductivity and high resistivity. This unique composition allows epoxy fiberglass to effectively impede the flow of electric current, even under substantial voltage differentials. The material's ability to maintain its insulative properties across a wide range of frequencies further enhances its versatility in electrical systems.

Exceptional Voltage Breakdown Strength

One of the most critical attributes of epoxy fiberglass sheets is their high voltage breakdown strength. This property refers to the maximum electric field the material can withstand before electrical breakdown occurs. Epoxy fiberglass exhibits a remarkably high breakdown strength, often exceeding 20 kV/mm. This characteristic enables the material to serve as a reliable barrier against electrical discharge in high voltage environments, preventing catastrophic failures and ensuring the longevity of electrical equipment.

Low Dielectric Loss

Epoxy fiberglass sheets demonstrate low dielectric loss, a crucial factor in high voltage applications. Dielectric loss represents the amount of electrical energy converted to heat within an insulating material when subjected to an alternating electric field. The low dielectric loss of epoxy fiberglass minimizes energy dissipation and heat generation, contributing to the overall efficiency and thermal management of high voltage devices. This property is particularly valuable in applications where maintaining stable operating temperatures is essential for optimal performance and longevity.

Dielectric Strength and Arc Resistance Explained

Understanding Dielectric Strength

Dielectric strength, often measured in volts per unit thickness, quantifies an insulating material's ability to withstand electric stress without breaking down. Epoxy fiberglass sheets exhibit exceptional dielectric strength, typically ranging from 20 to 40 kV/mm, depending on the specific composition and manufacturing process. This high dielectric strength enables epoxy fiberglass to maintain its insulative properties even when subjected to intense electric fields, making it an ideal choice for high voltage applications where electrical isolation is paramount.

Arc Resistance and Its Significance

Arc resistance refers to a material's ability to withstand electrical arcing without degradation or surface tracking. Epoxy fiberglass sheets demonstrate superior arc resistance, largely due to their composite nature and the inherent properties of the epoxy resin. This characteristic is crucial in high voltage environments where electrical discharges can occur, potentially leading to surface erosion and eventual insulation failure. The high arc resistance of epoxy fiberglass helps maintain the integrity of insulating components over extended periods, even under challenging operating conditions.

Factors Influencing Dielectric Performance

Several factors affect the dielectric performance of epoxy fiberglass sheets in high voltage applications. The glass fiber content and orientation, resin composition, and manufacturing process all play significant roles in determining the material's electrical properties. Environmental conditions, such as temperature and humidity, can also impact dielectric strength and arc resistance. Understanding these influencing factors is essential for selecting the appropriate epoxy fiberglass grade for specific high voltage applications and ensuring optimal performance throughout the device's operational life.

Applications in Transformers, Switchgear, and Power Distribution

Transformer Insulation Systems

Epoxy fiberglass sheets play a crucial role in transformer insulation systems. They are commonly used as barriers between windings, providing essential electrical isolation and mechanical support. The material's high dielectric strength ensures effective insulation between primary and secondary windings, while its dimensional stability helps maintain consistent performance under varying thermal conditions. Epoxy fiberglass components, such as spacers and end insulation, contribute to the overall reliability and efficiency of power transformers in both distribution and transmission networks.

Switchgear Components

In switchgear applications, epoxy fiberglass sheets are utilized for various insulating components. These include bus bar supports, phase barriers, and arc chutes. The material's excellent electrical insulation properties, combined with its mechanical strength and flame-retardant characteristics, make it ideal for use in medium and high voltage switchgear. Epoxy fiberglass components help prevent flashovers between live parts, contain and extinguish arcs during circuit interruption, and maintain the overall safety and reliability of switchgear systems.

Power Distribution Equipment

Epoxy fiberglass sheets find extensive use in power distribution equipment, such as circuit breakers, disconnect switches, and insulators. The material's ability to withstand high voltages and resist environmental factors makes it suitable for both indoor and outdoor applications. In circuit breakers, epoxy fiberglass components serve as insulating barriers and structural supports, ensuring safe and reliable operation during fault conditions. The material's versatility and performance characteristics contribute to the development of compact, efficient, and durable power distribution solutions across various voltage classes.

Conclusion

Epoxy fiberglass sheets have become indispensable in high voltage devices due to their exceptional electrical insulation properties, mechanical strength, and thermal stability. Their superior dielectric characteristics, high voltage breakdown strength, and excellent arc resistance make them ideal for use in transformers, switchgear, and power distribution equipment. As the demand for reliable and efficient high voltage systems continues to grow, epoxy fiberglass sheets will undoubtedly play a crucial role in shaping the future of electrical infrastructure, ensuring safe and efficient power transmission and distribution across various industries.

Contact Us

For more information about our high-quality epoxy fiberglass sheets and how they can benefit your high voltage applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Electrical Insulation Materials: A Comprehensive Guide to High Voltage Applications

2. Advanced Composites in Electrical Engineering: Properties and Performance

3. High Voltage Engineering: Fundamentals and Applications

4. Transformer Design Principles: With Applications to Core-Form Power Transformers

5. Switchgear and Protection: Modern Trends and Practices

6. Power System Insulation Coordination: Principles and Practice