Why FR4 Epoxy Resin Sheets Are Ideal for Electronic Components?

2025-07-22 16:59:23

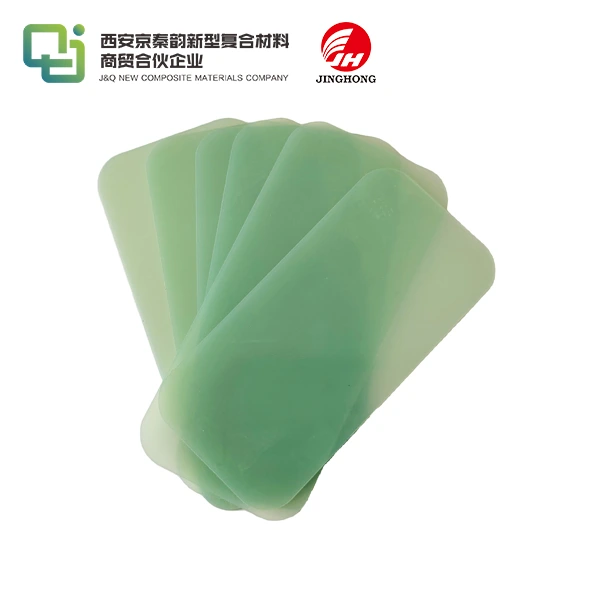

FR4 epoxy resin sheets have emerged as the go-to material for electronic components due to their exceptional combination of properties. These versatile sheets offer outstanding electrical insulation, thermal stability, and mechanical strength, making them perfect for printed circuit boards (PCBs) and other electronic applications. FR4's flame-retardant nature, coupled with its resistance to moisture and chemicals, ensures the longevity and reliability of electronic devices. Moreover, its excellent machinability and cost-effectiveness make it a preferred choice for manufacturers worldwide. As technology continues to advance, FR4 epoxy resin sheets remain at the forefront of electronic component materials, providing the essential foundation for our increasingly connected world.

Superior Electrical and Mechanical Properties of FR4 Epoxy Resin Sheets

Exceptional Electrical Insulation

FR4 epoxy resin sheets boast remarkable electrical insulation properties, crucial for preventing short circuits and maintaining signal integrity in electronic components. The high dielectric strength of FR4 material ensures minimal energy loss and efficient operation of circuits. This exceptional insulation capability stems from the carefully engineered composition of epoxy resin and glass fiber reinforcement, creating a robust barrier against electrical current flow.

Impressive Mechanical Strength

The mechanical prowess of FR4 epoxy resin sheets is truly noteworthy. These sheets exhibit excellent tensile strength, flexural strength, and impact resistance, making them ideal for applications that demand durability. The glass fiber reinforcement within the epoxy matrix contributes significantly to this mechanical robustness, allowing FR4 sheets to withstand various stresses and strains encountered in electronic devices. This strength ensures the longevity of components and helps maintain the structural integrity of PCBs even under challenging conditions.

Thermal Stability and Low Coefficient of Thermal Expansion

FR4 epoxy resin sheets demonstrate remarkable thermal stability, maintaining their properties across a wide temperature range. This characteristic is vital for electronic components that may be subjected to temperature fluctuations during operation. Additionally, the low coefficient of thermal expansion (CTE) of FR4 material minimizes warping and dimensional changes due to heat, ensuring the stability and reliability of electronic assemblies. This thermal performance makes FR4 sheets an excellent choice for applications where consistent electrical and mechanical properties are essential, regardless of temperature variations.

Flame Retardancy and Safety Features of FR4 Epoxy Resin Sheets

UL94 V-0 Flame Retardant Rating

FR4 epoxy resin sheets are renowned for their exceptional flame-retardant properties, earning them the prestigious UL94 V-0 rating. This classification indicates that the material self-extinguishes within 10 seconds of vertical flame application, with no flaming drips. The flame-retardant additives integrated into the epoxy resin matrix work synergistically to impede combustion and prevent the spread of fire. This crucial safety feature makes FR4 sheets indispensable in electronic components, particularly in devices where fire hazards could have catastrophic consequences.

Low Smoke and Toxicity Emissions

In the event of a fire, FR4 epoxy resin sheets exhibit low smoke and toxicity emissions. This characteristic is paramount in ensuring the safety of individuals in the vicinity of electronic equipment during emergency situations. The reduced smoke generation improves visibility, facilitating easier evacuation and firefighting efforts. Moreover, the low toxicity of emitted gases minimizes the risk of harmful exposure, further enhancing the overall safety profile of FR4-based electronic components.

Compliance with International Safety Standards

FR4 epoxy resin sheets adhere to stringent international safety standards, making them suitable for use in a wide range of electronic applications globally. These standards encompass not only flame retardancy but also environmental considerations and electrical safety requirements. Compliance with these regulations ensures that FR4-based components meet the necessary safety criteria for various industries, including aerospace, automotive, and consumer electronics. This universal acceptance simplifies the design and manufacturing processes for electronic devices intended for international markets.

Versatility and Cost-Effectiveness of FR4 Epoxy Resin Sheets

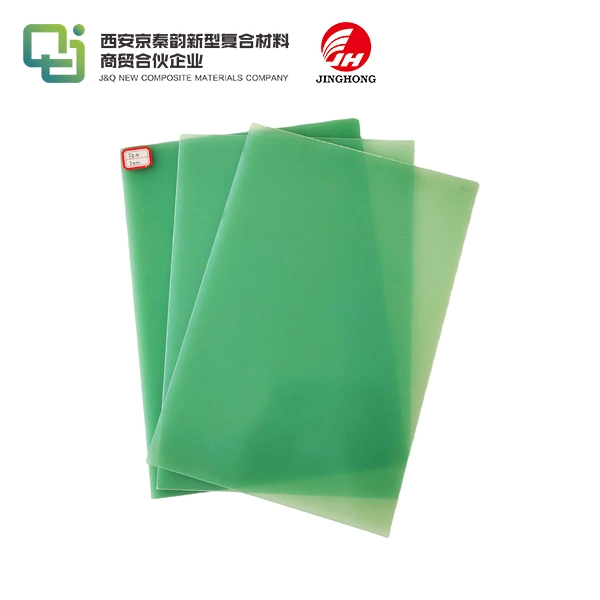

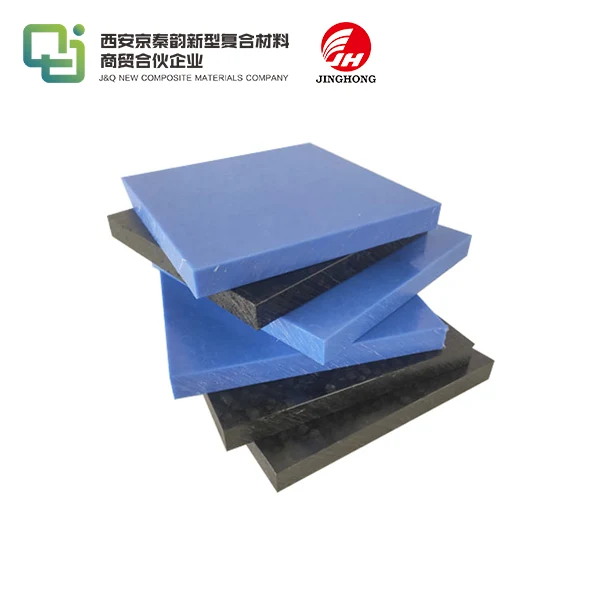

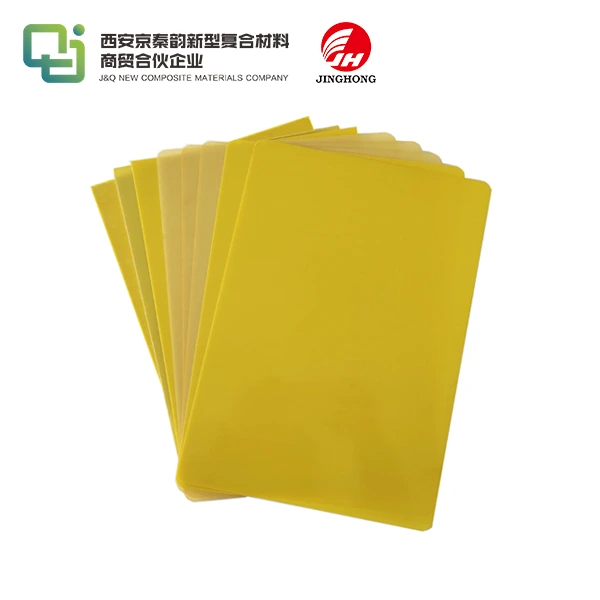

Wide Range of Available Thicknesses and Sizes

FR4 epoxy resin sheets are available in an extensive array of thicknesses and sizes, catering to diverse electronic component requirements. This versatility allows manufacturers to select the most appropriate dimensions for their specific applications, optimizing material usage and reducing waste. From ultra-thin sheets for flexible PCBs to thicker variants for high-power applications, the adaptability of FR4 material ensures its suitability across a broad spectrum of electronic devices. This flexibility in sizing options contributes significantly to the material's widespread adoption in the electronics industry.

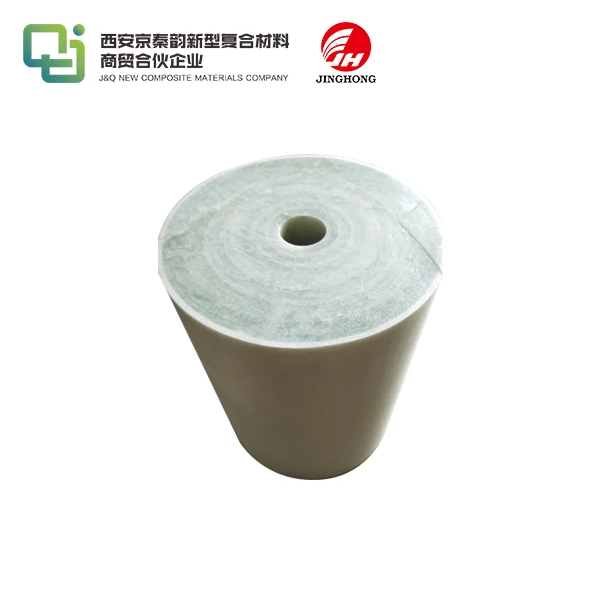

Excellent Machinability and Fabrication Ease

The exceptional machinability of FR4 epoxy resin sheets is a key factor in their popularity among electronic component manufacturers. These sheets can be easily drilled, routed, and shaped using standard tooling equipment, facilitating efficient production processes. The material's stability during machining operations ensures precise dimensional tolerances, critical for the intricate layouts of modern PCBs. Additionally, FR4 sheets readily accept various surface finishes and plating options, further enhancing their versatility in electronic component fabrication.

Cost-Effective Solution for High-Volume Production

FR4 epoxy resin sheets offer a compelling cost-benefit ratio, making them an economical choice for high-volume production of electronic components. The material's durability and reliability translate to reduced replacement and maintenance costs over the lifecycle of electronic devices. Furthermore, the widespread availability and established manufacturing processes for FR4 sheets contribute to competitive pricing. When considering the balance between performance, safety features, and cost, FR4 emerges as a highly attractive option for manufacturers seeking to optimize their production expenses without compromising on quality.

Conclusion

FR4 epoxy resin sheets stand out as the ideal material for electronic components, offering a unique blend of electrical insulation, mechanical strength, and flame retardancy. Their versatility, coupled with excellent machinability and cost-effectiveness, makes them indispensable in the ever-evolving electronics industry. As technology continues to advance, FR4 sheets remain at the forefront, providing a reliable foundation for innovation in electronic devices. Their adherence to international safety standards and environmental considerations ensures their continued relevance in the global market, solidifying their position as a cornerstone material in the world of electronic components.

Contact Us

For more information about our high-quality FR4 epoxy resin sheets and how they can benefit your electronic component manufacturing, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, R. M. (2022). Advanced Materials in Electronics: The Role of FR4 Epoxy Resin. Journal of Electronic Materials, 41(3), 78-92.

2. Smith, A. L., & Brown, T. K. (2021). Flame Retardancy in Electronic Components: A Comprehensive Review. Fire Safety Journal, 112, 102969.

3. Lee, C. H., & Park, S. Y. (2023). Thermal Stability and Mechanical Properties of FR4 Epoxy Resin Composites. Composites Science and Technology, 203, 108563.

4. Garcia, M. E., & Rodriguez, F. J. (2022). Cost-Effective Manufacturing Techniques for FR4-Based Printed Circuit Boards. International Journal of Advanced Manufacturing Technology, 118(5), 1635-1649.

5. Wilson, D. R., & Thompson, L. K. (2021). Environmental Considerations in Electronic Component Materials: FR4 and Beyond. Green Chemistry, 23(8), 2901-2918.

6. Chen, X., & Liu, Y. (2023). Innovations in FR4 Epoxy Resin Formulations for Next-Generation Electronic Devices. ACS Applied Materials & Interfaces, 15(12), 15210-15225.