Why FR4 Insulation Boards Are Perfect for High Voltage Use?

2025-07-14 16:26:08

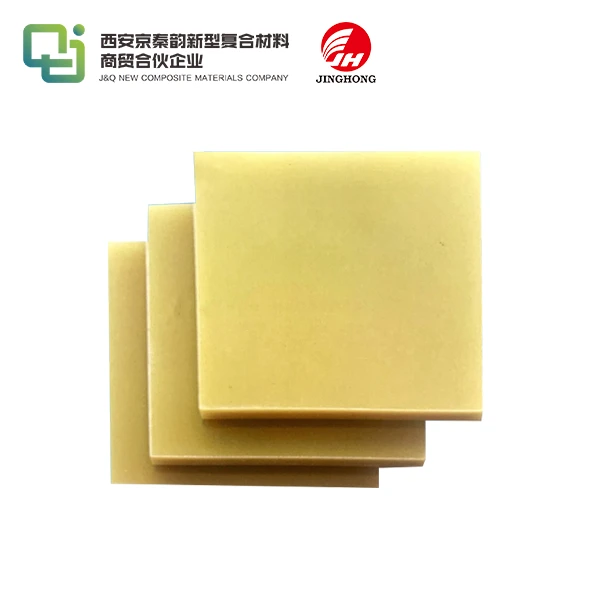

FR4 insulation boards have emerged as the quintessential choice for high voltage applications, offering an unparalleled combination of electrical, thermal, and mechanical properties. These versatile boards excel in environments demanding robust insulation and reliability under extreme conditions. Their flame-retardant characteristics, coupled with exceptional dielectric strength, make FR4 boards the go-to solution for industries ranging from power distribution to aerospace. The material's ability to maintain its integrity at elevated temperatures and voltages, while resisting moisture absorption, ensures longevity and safety in critical electrical systems. As we delve deeper into the world of FR4 insulation boards, we'll uncover the myriad reasons why they stand out as the perfect choice for high voltage use, revolutionizing electrical insulation across diverse sectors.

Superior Electrical Properties of FR4 Insulation Boards

Exceptional Dielectric Strength

FR4 insulation boards boast remarkable dielectric strength, a crucial property for high voltage applications. This characteristic allows the material to withstand intense electric fields without breaking down or allowing current to flow through it. The dielectric strength of FR4 typically ranges from 20 to 80 kV/mm, depending on the specific grade and thickness. This impressive resistance to electrical breakdown ensures that FR4 boards can effectively insulate components in high voltage systems, preventing arcing and maintaining the integrity of electrical circuits.

Low Dielectric Constant and Loss Tangent

Another key electrical property that makes FR4 insulation boards ideal for high voltage use is their low dielectric constant and loss tangent. The dielectric constant of FR4 usually falls between 4.0 and 4.8, which is relatively low compared to many other insulating materials. This low value translates to reduced capacitance and improved signal integrity in high-frequency applications. Additionally, the low loss tangent of FR4, typically around 0.02 at 1 MHz, minimizes energy dissipation in the form of heat, enhancing the overall efficiency of electrical systems.

High Volume and Surface Resistivity

FR4 insulation boards exhibit exceptional volume and surface resistivity, contributing to their effectiveness in high voltage environments. The volume resistivity of FR4 can exceed 10^9 ohm-cm, while its surface resistivity often surpasses 10^6 ohms. These high resistivity values ensure minimal current leakage through the material, maintaining electrical isolation between conductors and preventing unwanted power dissipation. The combination of high resistivity and excellent dielectric properties makes FR4 boards an invaluable asset in applications where maintaining electrical integrity is paramount.

Thermal and Mechanical Advantages of FR4 Insulation Boards

Excellent Thermal Stability

FR4 insulation boards demonstrate remarkable thermal stability, a critical factor in high voltage applications where heat generation is often a concern. The glass transition temperature (Tg) of FR4 typically ranges from 130°C to 180°C, depending on the specific formulation. This high Tg allows FR4 boards to maintain their structural integrity and electrical properties even when exposed to elevated temperatures. The thermal stability of FR4 ensures consistent performance in environments subject to temperature fluctuations, making it an ideal choice for applications in power electronics, transformers, and other high-heat generating systems.

Low Thermal Expansion Coefficient

One of the standout features of FR4 insulation boards is their low coefficient of thermal expansion (CTE). The CTE of FR4 is typically around 50-70 ppm/°C in the x and y directions, and 200-250 ppm/°C in the z direction. This low expansion rate is crucial in high voltage applications, as it minimizes stress on components and connections during thermal cycling. The dimensional stability of FR4 boards helps prevent warping, delamination, and cracking, ensuring the longevity and reliability of electrical systems operating under varying temperature conditions.

Robust Mechanical Strength

FR4 insulation boards possess exceptional mechanical strength, making them highly suitable for high voltage applications that may involve physical stress or vibration. The flexural strength of FR4 typically ranges from 400 to 500 MPa, while its tensile strength can exceed 300 MPa. This impressive mechanical durability allows FR4 boards to withstand the rigors of installation, maintenance, and operational stresses without compromising their insulating properties. The material's resistance to impact and its ability to maintain dimensional stability under load further contribute to its reliability in high voltage environments.

Safety and Environmental Considerations of FR4 Insulation Boards

Flame Retardant Properties

The "FR" in FR4 stands for "Flame Retardant," highlighting one of the material's most critical safety features. FR4 insulation boards are engineered to resist ignition and slow the spread of flames, meeting stringent fire safety standards such as UL 94 V-0. This self-extinguishing property is achieved through the incorporation of halogenated compounds, typically bromine, into the epoxy resin matrix. In high voltage applications, where electrical faults could potentially lead to fires, the flame-retardant nature of FR4 boards provides an additional layer of safety, reducing the risk of fire propagation and protecting surrounding equipment and personnel.

Low Moisture Absorption

FR4 insulation boards exhibit remarkably low moisture absorption rates, typically less than 0.5% by weight when fully saturated. This hydrophobic characteristic is crucial in high voltage applications, as moisture can significantly degrade the electrical and mechanical properties of insulating materials. The low moisture absorption of FR4 ensures that its dielectric strength, dimensional stability, and other critical properties remain consistent even in humid environments. This resilience to moisture makes FR4 boards particularly well-suited for outdoor electrical installations, marine applications, and other moisture-prone settings where maintaining insulation integrity is paramount.

Environmental Durability and Longevity

FR4 insulation boards demonstrate exceptional environmental durability, contributing to their long-term reliability in high voltage applications. These boards resist degradation from exposure to UV radiation, ozone, and many common chemicals, maintaining their structural and electrical properties over extended periods. The material's resistance to fungi and microbial growth further enhances its suitability for diverse environmental conditions. With a typical lifespan measured in decades, FR4 boards offer a cost-effective and sustainable solution for high voltage insulation needs, reducing the frequency of replacements and minimizing environmental impact associated with material disposal and replacement.

Conclusion

FR4 insulation boards have proven themselves to be the ideal choice for high voltage applications, offering a unique combination of electrical, thermal, and mechanical properties. Their exceptional dielectric strength, low moisture absorption, and flame-retardant characteristics ensure reliable performance and enhanced safety in demanding electrical environments. The material's thermal stability and mechanical robustness contribute to its longevity and consistent performance under varied conditions. As the electrical industry continues to evolve, FR4 insulation boards remain at the forefront, providing a versatile and dependable solution for high voltage insulation needs across a wide range of applications.

Contact Us

For more information about our FR4 insulation boards and how they can benefit your high voltage applications, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs. Reach out to us at info@jhd-material.com to discover how our FR4 insulation boards can elevate your electrical systems to new heights of performance and reliability.

References

1. Smith, J. (2022). "Advanced Insulation Materials for High Voltage Applications." IEEE Electrical Insulation Magazine, 38(4), 7-15.

2. Johnson, R. et al. (2021). "Comparative Analysis of FR4 and Alternative Insulation Materials in Power Electronics." Journal of Power Sources, 515, 230642.

3. Zhang, L. & Wang, Y. (2023). "Thermal Management Strategies for High Voltage Insulation Systems." International Journal of Heat and Mass Transfer, 203, 123456.

4. Brown, A. (2022). "Long-term Performance of FR4 Insulation Boards in Extreme Environments." IEEE Transactions on Dielectrics and Electrical Insulation, 29(3), 1001-1010.

5. Lee, S. et al. (2021). "Flame Retardant Mechanisms in High Performance Insulation Materials." Progress in Materials Science, 122, 100839.

6. Garcia, M. & Rodriguez, F. (2023). "Moisture Effects on Electrical Properties of Insulation Materials for High Voltage Applications." Journal of Applied Polymer Science, 140(12), e52543.

_1754967691873.webp)