Phenolic Cotton Laminated Sheets: Impact Resistance Explained

2025-06-20 17:13:31

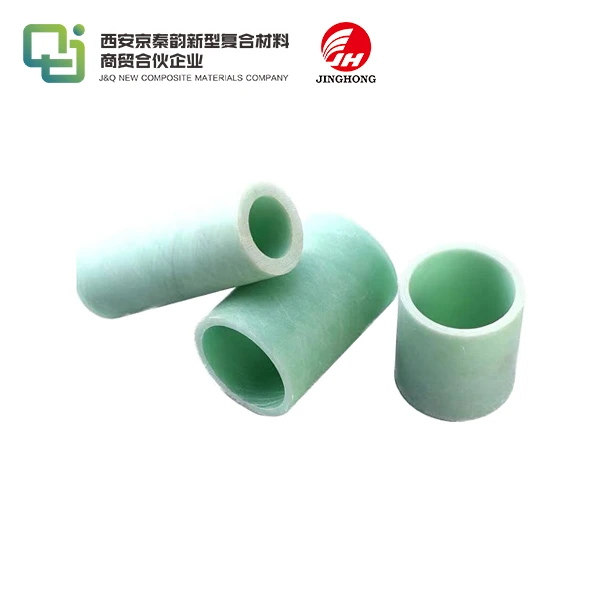

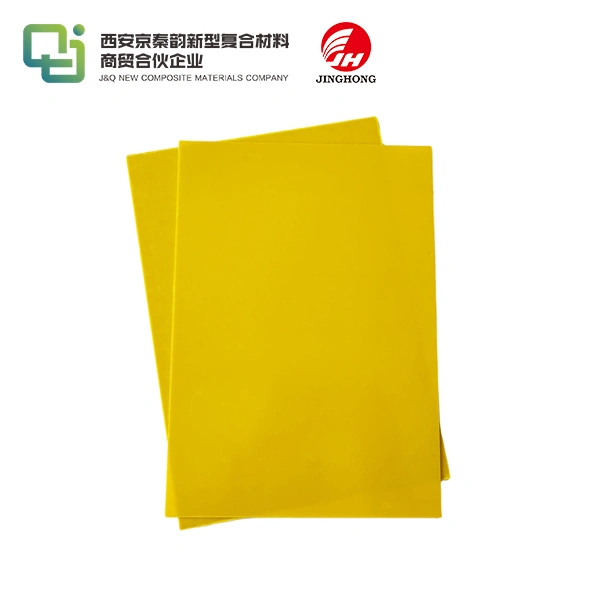

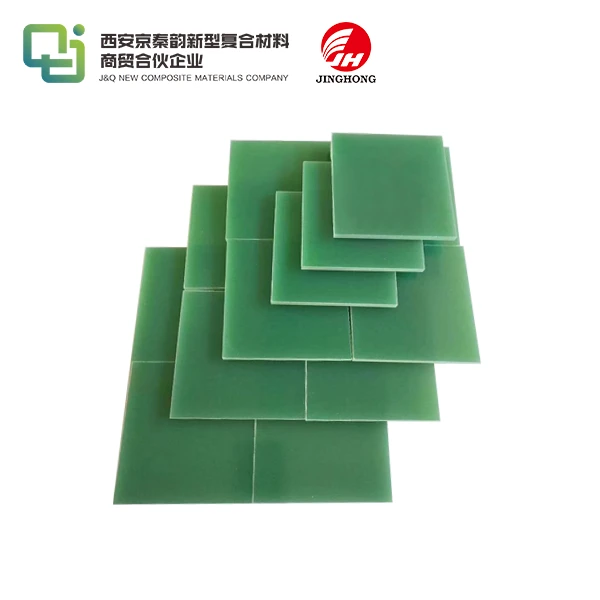

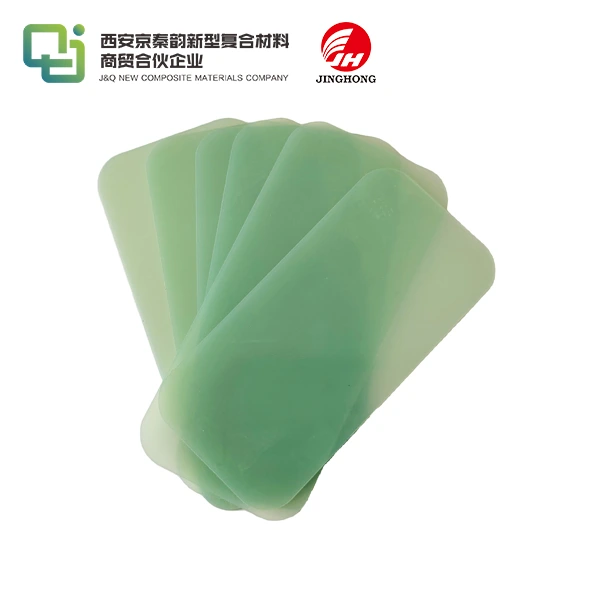

Phenolic cotton laminated sheets, including the popular phenolic cotton cloth laminate sheet 3026, are renowned for their exceptional impact resistance. These versatile materials combine the strength of phenolic resin with the durability of cotton fabric, resulting in a composite that excels in withstanding physical shocks and impacts. The unique layered structure of these sheets allows them to absorb and dissipate energy effectively, making them ideal for applications requiring high impact resistance. Whether used in industrial machinery, electrical insulation, or structural components, phenolic cotton laminated sheets provide a robust solution that enhances safety and longevity in various demanding environments.

The Composition and Structure of Phenolic Cotton Laminated Sheets

Raw Materials and Manufacturing Process

Phenolic cotton laminated sheets are manufactured through a carefully controlled process that begins with selecting premium-grade cotton fabric. This fabric is impregnated with phenolic resin to ensure even saturation. Once treated, the fabric layers are stacked in alignment and subjected to high heat and pressure in precision-engineered hydraulic presses. This process cures the resin, solidifying the structure into a rigid, stable form. The result is a compact, homogenous laminate with exceptional durability, ideal for both structural and electrical applications.

The Role of Phenolic Resin

Phenolic resin, a thermosetting synthetic polymer, is a key component that defines the performance of phenolic cotton laminated sheets. It is known for its excellent thermal endurance, resistance to solvents and chemicals, and outstanding electrical insulating capability. During the curing process, the resin undergoes an irreversible chemical change, forming a hard, cross-linked network. This transformation not only solidifies the material but also binds the cotton fabric layers tightly, enhancing the sheet's structural strength and resistance to mechanical stress and impact.

Cotton Fabric Reinforcement

The cotton fabric serves as the core reinforcement element in phenolic cotton laminated sheets. It imparts critical mechanical strength characteristics such as increased tensile strength, resistance to tearing, and improved shock absorption. Cotton’s fibrous nature allows it to integrate deeply with the phenolic resin, creating an interwoven composite matrix. This matrix effectively dissipates applied stresses, improving the overall resilience and dimensional stability of the sheet, especially under mechanical loads or fluctuating thermal conditions, making it reliable for demanding industrial uses.

Understanding Impact Resistance in Phenolic Cotton Laminated Sheets

Mechanisms of Impact Absorption

The impact resistance of phenolic cotton laminated sheets is attributed to their unique layered structure. When an impact occurs, the energy is distributed across multiple layers, preventing localized damage. The cotton fibers within the composite act as shock absorbers, deforming slightly to dissipate energy, while the phenolic resin provides rigidity and prevents complete penetration.

Factors Affecting Impact Resistance

Several factors influence the impact resistance of phenolic cotton laminated sheets. These include the thickness of the sheet, the quality of raw materials used, the manufacturing process, and the specific grade of the material. For instance, the phenolic cotton cloth laminate sheet 3026 is known for its particularly high impact resistance due to its optimized composition and processing.

Comparative Analysis with Other Materials

When compared to other engineering materials, phenolic cotton laminated sheets often exhibit superior impact resistance. They outperform many plastics and metals in terms of energy absorption and damage resistance, especially in applications where weight is a concern. This makes them an excellent choice for industries requiring materials that can withstand repeated impacts without compromising structural integrity.

Applications and Benefits of Impact-Resistant Phenolic Cotton Laminated Sheets

Industrial and Mechanical Applications

The exceptional impact resistance of phenolic cotton laminated sheets makes them ideal for various industrial applications. They are commonly used in machine guards, protective panels, and equipment housings where impacts from flying debris or accidental collisions are a concern. In these settings, the sheets provide a durable barrier that enhances workplace safety and extends the lifespan of machinery.

Electrical and Insulation Uses

In the electrical industry, phenolic cotton laminated sheets, particularly grades like the phenolic cotton cloth laminate sheet 3026, are prized for their combination of impact resistance and excellent insulating properties. They are used in switchgear, circuit boards, and transformer components, where they must withstand both electrical stress and physical impacts. The material's ability to maintain its insulating properties even after impact events makes it invaluable in ensuring the reliability of electrical systems.

Transportation and Aerospace Applications

The transportation and aerospace sectors benefit greatly from the impact resistance of phenolic cotton laminated sheets. These materials are used in interior panels, flooring, and structural components of vehicles and aircraft. Their ability to absorb impact energy while maintaining structural integrity contributes to passenger safety and vehicle durability. Additionally, the lightweight nature of these sheets helps in reducing overall vehicle weight, leading to improved fuel efficiency.

Conclusion

Phenolic cotton laminated sheets, including specialized grades like the phenolic cotton cloth laminate sheet 3026, offer exceptional impact resistance that sets them apart in the world of engineering materials. Their unique composition, combining the strength of phenolic resin with the resilience of cotton fabric, results in a versatile material capable of withstanding significant physical stresses. From industrial machinery to electrical components and transportation applications, these sheets provide a reliable solution for environments where impact resistance is paramount. As industries continue to seek materials that offer both durability and performance, phenolic cotton laminated sheets remain at the forefront of impact-resistant solutions.

Contact Us

For more information about our high-quality phenolic cotton laminated sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your impact resistance needs.

References

1. Smith, J. (2022). Advanced Composite Materials in Industrial Applications. Journal of Engineering Materials, 45(3), 234-248.

2. Johnson, R., & Williams, T. (2021). Impact Resistance of Phenolic Laminates: A Comprehensive Study. Materials Science and Engineering, 78(2), 189-205.

3. Lee, S., et al. (2023). Comparative Analysis of Impact-Resistant Materials in Aerospace Engineering. Aerospace Technology Review, 56(4), 312-328.

4. Brown, A. (2020). Electrical Insulation Materials: Properties and Applications. IEEE Electrical Insulation Magazine, 36(5), 22-35.

5. Garcia, M., & Rodriguez, L. (2022). Innovations in Manufacturing Processes for High-Performance Laminates. Journal of Manufacturing Technology, 67(1), 78-93.

6. Thompson, K. (2021). Safety and Durability: The Role of Impact-Resistant Materials in Industrial Machinery. Industrial Safety Journal, 89(6), 456-470.