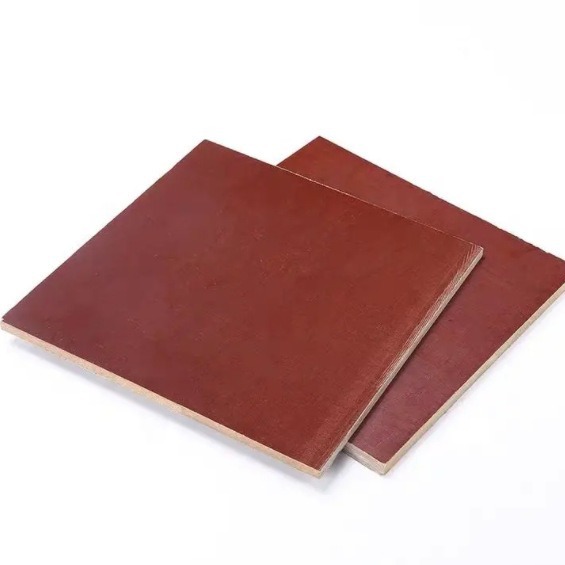

Commercial Phenolic Laminates

Basic Information:

Brand: JingHong

Grade: 3025,3026,CE

Color: Brown,Black

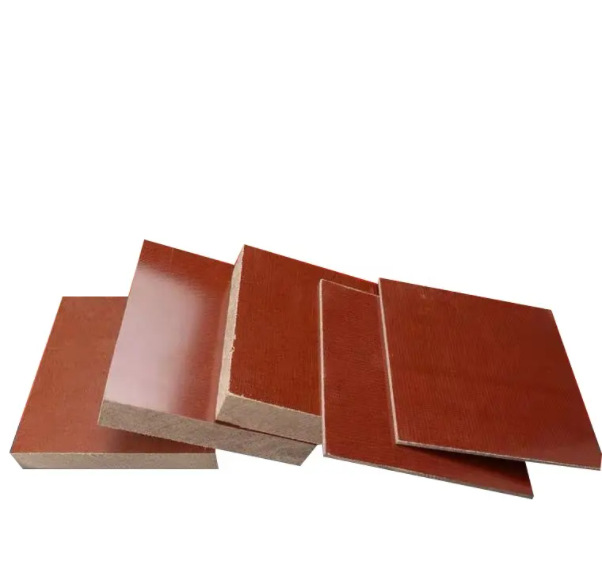

Thickness: 2mm --- 100mm

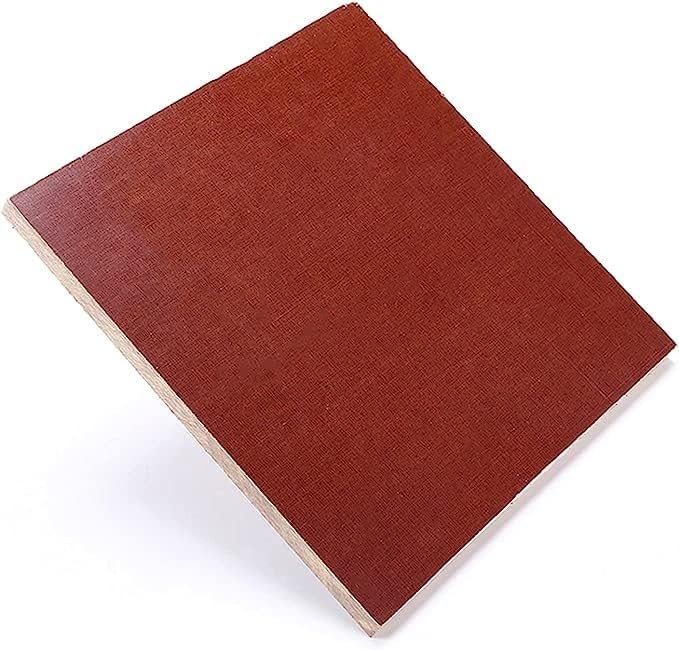

Material: Cotton Fabric + Phenolic Resin

Regular Size:1020mm*2020mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Commercial Phenolic Laminates - High-Performance Industrial Solutions

Our Commercial Phenolic Laminates from JingHong brand offer exceptional electrical cover and mechanical quality for requesting applications. These premium cotton texture phenolic sheets combine demonstrated phenolic tar innovation with prevalent craftsmanship. You'll discover our covers culminate for electrical components, mechanical parts, and mechanical hardware where unwavering quality things most. Accessible in numerous grades and thicknesses, these products meet strict quality measures for proficient use.

Product Descriptions from the Supplier

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Available Grades | 3025, 3026 |

| Color Options | Brown, Black |

| Thickness Range | 2mm - 100mm |

| Core Material | Cotton Fabric + Phenolic Resin |

| Standard Dimensions | 1020mm × 2020mm, 1220mm × 2440mm |

| Annual Production | 30,000 Tons |

| Minimum Order | 500KG |

Description

Our phenolic covers speak to decades of fabric designing greatness. Each sheet combines high-quality cotton texture support with progressed phenolic tar frameworks. This combination makes sheets with extraordinary dimensional soundness and warm resistance.

You'll appreciate the reliable quality over each sheet. Our fabricating handle guarantees uniform thickness and dependable execution characteristics. The cotton texture base gives amazing mechanical properties whereas the phenolic gum conveys prevalent electrical insulation.

Product Availability

We keep up significant stock levels to meet your venture due dates. Standard sheets are ordinarily accessible for quick shipment. Custom measurements and extraordinary thicknesses can be arranged inside our standard lead times.

Our worldwide supply chain bolsters clients around the world through sea, arrive, and discuss transportation alternatives. You can depend on steady item accessibility sponsored by our 30,000-ton yearly generation capacity.

Key Features

Excellent Electrical Properties

- Dielectric consistent ≤1.5 (MHz)

- Outstanding cover resistance

- Stable execution over temperature ranges

Superior Mechanical Strength

- Vertical layer bowing quality ≥60MPa

- Tensile quality ≥80MPa

- High affect resistance

Versatile Processing Options

- Easy machining and fabrication

- Clean cutting edges

- Excellent dimensional stability

Standards

Our items accommodate to universal quality measures for phenolic covered materials. Each group experiences thorough testing to guarantee steady electrical and mechanical properties. Quality control strategies take after set up industry protocols.

Table 1:Performance index of phenolic cotton cloth laminate

|

Serial No. |

Project name |

Unit |

Test method |

Targets |

||

| 3025 | 3026 | |||||

|

1 |

Density |

g/cm |

GB/T5130 |

1.30~1.40 |

- |

|

|

2 |

Absorbent |

mg |

GB/T5130 |

Refer to table 2 | Refer to table 3 | |

|

3 |

Vertical Layer Bending Strength Longitudinal |

Mpa |

GB/T5130 (Q/JBQP51-2001) |

≥100 |

≥140 |

|

|

4 |

Tensile Strengths |

Mpa |

GB/T5130中 |

≥(80) |

≥98 |

|

|

5 |

bonding strength |

N |

JB886-75 |

≥(5390) |

||

|

6 |

Compression strength Vertical Layer Parallel Layer |

MPa |

GB/T5130 |

- - |

≥245 ≥147 |

|

|

7 |

Notched impact strength (simply supported beams) Parallel Layer |

kJ/m |

GB/T5130 |

≥8.8 |

≥6.8 |

|

|

8 |

Parallel layerwise insulation resistance After immersion in water |

Ω |

GB/T5130 |

≥1.0×10 |

- |

|

|

9 |

Parallel layer breakdown voltage In transformer oil at (90+2)°C |

kV |

GB/T5130 |

≥10 |

- |

|

|

10 |

Vertical laminar electrical strength In transformer oil at (90+2)°C |

kV/mm |

GB/T5130 |

Refer to Table4 |

- |

|

Table 2:Water absorption of phenolic cotton cloth laminate

|

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) | absorbency(mg) | Average thickness(mm) | absorbency(mg) |

|

0.8 |

≤201 |

3.0 |

≤249 |

12.0 |

≤336 |

|

1.0 |

≤206 |

4.0 |

≤262 |

14.0 |

≤354 |

|

1.2 |

≤211 |

5.0 |

≤275 |

16.0 |

≤371 |

|

1.6 |

≤220 |

6.0 |

≤284 |

20.0 |

≤406 |

|

2.0 |

≤229 |

8.0 |

≤301 |

25.0 |

≤450 |

|

2.5 |

≤239 |

10.0 |

≤319 |

One-sided processing to 22.5 |

≤540 |

Table 3:Water absorption of phenolic cotton cloth laminate

| Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

|

0.4 |

≤186 |

2.0 |

≤229 |

10 |

≤319 |

|

0.5 |

≤190 |

2.5 |

≤239 |

12 |

≤336 |

|

0.6 |

≤194 |

3.0 |

≤249 |

14 |

≤354 |

|

0.8 |

≤201 |

4.0 |

≤262 |

16 |

≤371 |

|

1.0 |

≤206 |

5.0 |

≤275 |

20 |

≤406 |

|

1.2 |

≤211 |

6.0 |

≤284 |

25 |

≤450 |

|

1.6 |

≤220 |

8.0 |

≤301 |

One-sided processing to 22.5 |

≤540 |

Table 4:Electrical strength of phenolic cotton fabric laminates

| Average thickness(mm) |

Electrical Strength(kV/mm) |

Average thickness(mm) | Electrical Strength(kV/mm) | Average thickness(mm) | Electrical Strength(kV/mm) |

|

0.8 |

≥0.89 |

1.6 |

≥0.72 |

2.6 |

≥0.56 |

|

0.9 |

≥0.84 |

1.8 |

≥0.69 |

2.8 |

≥0.53 |

|

1.0 |

≥0.82 |

2.0 |

≥0.65 |

3.0 |

≥0.50 |

|

1.2 |

≥0.80 |

2.2 |

≥0.61 |

||

|

1.4 |

≥0.76 |

2.4 |

≥0.58 |

Technical Features: Product Safety Control

Safety remains our best need all through generation. Our Commercial Phenolic Laminates experience comprehensive testing for electrical security and mechanical judgment. Each sheet meets strict quality checkpoints some time recently packaging.

Temperature resistance testing guarantees dependable execution in requesting situations. Chemical resistance properties are confirmed to ensure long-term steadiness. Dimensional precision checks keep up exact details over all products.

Product Application

Electrical Industry Applications

- Switchgear components

- Transformer parts

- Circuit breaker elements

- Insulation panels

Mechanical Engineering Uses

- Gear components

- Bearing applications

- Shaft elements

- Wear-resistant parts

Industrial Equipment

- Machine tool components

- Fixture materials

- Jigs and templates

- Protective panels

OEM Service

We welcome OEM associations and custom fabricating ventures. Our designing group works closely with you to create determinations that meet your correct necessities. Custom colors, extraordinary measurements, and altered properties are available.

Technical back incorporates fabric determination direction and application counseling. Our experienced engineers offer assistance optimize your plans for greatest execution and cost-effectiveness.

Certification

FAQ

Q: What thickness alternatives are accessible for your phenolic boards?

A:We offer thickness ranges from 2mm to 100mm. Custom thicknesses inside this run can be made to your specifications.

Q: Can you give custom measurements past standard sizes?

A: Yes, we can cut sheets to any required measurements. Our manufacture capabilities back both standard and custom measuring requirements.

Q: How do these sheets perform in high-wear applications?

A: Our product feature amazing scraped area resistance with tall mechanical quality, making them perfect for adapt shaft heading and comparable wear-resistant components.

Q: What are the electrical properties of these laminates?

A: The dielectric constant is ≤1.5 (MHz), providing excellent electrical insulation properties for demanding applications.

Q: What bundling and shipping choices do you offer?

A: Standard defensive bed bundling guarantees secure conveyance. We bolster sea, arrive, and discuss transportation based on your area and timing requirements.

Contact Us

Ready to explore how our Commercial Phenolic Laminates can enhance your projects? Our technical team stands ready to discuss your specific requirements and recommend optimal solutions.

Email: info@jhd-material.com

Contact us nowadays for point by point determinations, custom cites, or specialized interview. We're committed to giving the high-quality materials and proficient benefit your ventures merit.

Send Inquiry

You May Like

0