Phenolic Glass Laminates

Basic Information:

Brand: JingHong

Grade: 3025,3026

Color: Brown,Black

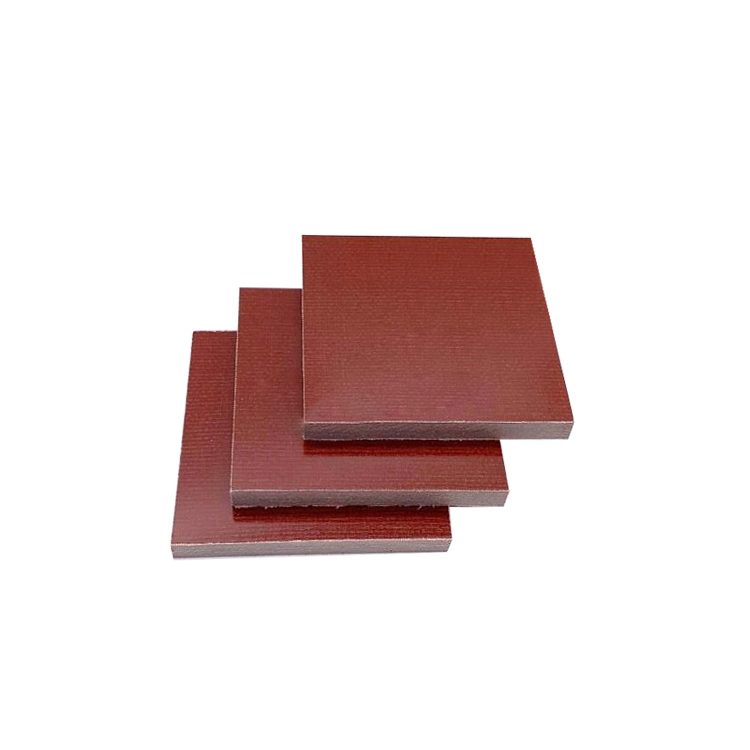

Thickness: 2mm --- 100mm

Material: Cotton Fabric + Phenolic Resin

Regular Size:1020mm*2020mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Phenolic Glass Laminates - High-Performance Insulating Solutions

Our Phenolic Glass Laminates offer extraordinary mechanical quality and warm soundness for requesting situations. These progressed composite materials combine phenolic gum with high-quality support textures to provide exceptional execution in electrical, mechanical, and engine applications. Whether you require protection auxiliary components or solid mechanical parts, our phenolic covers give the unwavering quality and flexibility your ventures require.

Description

Our phenolic covered sheets speak to cutting-edge composite innovation. These materials include a vigorous development utilizing phenolic gum framework combined with premium fortification textures. The fabricating handle guarantees steady quality and uniform properties all through each sheet.

Available in numerous grades and thicknesses, these covers meet differing mechanical necessities. The brown and dark color choices give adaptability for diverse stylish and utilitarian needs. Each sheet experiences thorough quality control to guarantee ideal execution characteristics.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Grades Available | 3025, 3026 |

| Colors | Brown, Black |

| Thickness Range | 2mm - 100mm |

| Standard Sizes | 1020mm × 2020mm, 1220mm × 2440mm |

| Minimum Order Quantity | 500KG |

| Annual Production Capacity | 30,000 Tons |

Key Features

- Superior Mechanical Quality - Tall compressive and flexural quality for requesting applications

- Excellent Electrical Separator - Extraordinary dielectric properties for electrical equipment

- Thermal Soundness - Keeps up execution over wide temperature ranges

- Easy Machining - Can be cut, penetrated, and ground with standard tools

- Chemical Resistance - Withstands introduction to different mechanical chemicals

- Dimensional Solidness - Keeps up shape and estimate beneath mechanical stress

Standards

Our phenolic composite materials comply with universal quality measures for electrical protection materials. These guidelines guarantee reliable execution and unwavering quality over distinctive applications. Each bunch experiences comprehensive testing to confirm compliance with indicated requirements.

Table 1:Performance index of phenolic cotton cloth laminate

|

Serial No. |

Project name |

Unit |

Test method |

Targets |

||

| 3025 | 3026 | |||||

|

1 |

Density |

g/cm |

GB/T5130 |

1.30~1.40 |

- |

|

|

2 |

Absorbent |

mg |

GB/T5130 |

Refer to table 2 | Refer to table 3 | |

|

3 |

Vertical Layer Bending Strength Longitudinal |

Mpa |

GB/T5130 (Q/JBQP51-2001) |

≥100 |

≥140 |

|

|

4 |

Tensile Strengths |

Mpa |

GB/T5130中 |

≥(80) |

≥98 |

|

|

5 |

bonding strength |

N |

JB886-75 |

≥(5390) |

||

|

6 |

Compression strength Vertical Layer Parallel Layer |

MPa |

GB/T5130 |

- - |

≥245 ≥147 |

|

|

7 |

Notched impact strength (simply supported beams) Parallel Layer |

kJ/m |

GB/T5130 |

≥8.8 |

≥6.8 |

|

|

8 |

Parallel layerwise insulation resistance After immersion in water |

Ω |

GB/T5130 |

≥1.0×10 |

- |

|

|

9 |

Parallel layer breakdown voltage In transformer oil at (90+2)°C |

kV |

GB/T5130 |

≥10 |

- |

|

|

10 |

Vertical laminar electrical strength In transformer oil at (90+2)°C |

kV/mm |

GB/T5130 |

Refer to Table4 |

- |

|

Table 2:Water absorption of phenolic cotton cloth laminate

|

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) | absorbency(mg) | Average thickness(mm) | absorbency(mg) |

|

0.8 |

≤201 |

3.0 |

≤249 |

12.0 |

≤336 |

|

1.0 |

≤206 |

4.0 |

≤262 |

14.0 |

≤354 |

|

1.2 |

≤211 |

5.0 |

≤275 |

16.0 |

≤371 |

|

1.6 |

≤220 |

6.0 |

≤284 |

20.0 |

≤406 |

|

2.0 |

≤229 |

8.0 |

≤301 |

25.0 |

≤450 |

|

2.5 |

≤239 |

10.0 |

≤319 |

One-sided processing to 22.5 |

≤540 |

Table 3:Water absorption of phenolic cotton cloth laminate

| Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

|

0.4 |

≤186 |

2.0 |

≤229 |

10 |

≤319 |

|

0.5 |

≤190 |

2.5 |

≤239 |

12 |

≤336 |

|

0.6 |

≤194 |

3.0 |

≤249 |

14 |

≤354 |

|

0.8 |

≤201 |

4.0 |

≤262 |

16 |

≤371 |

|

1.0 |

≤206 |

5.0 |

≤275 |

20 |

≤406 |

|

1.2 |

≤211 |

6.0 |

≤284 |

25 |

≤450 |

|

1.6 |

≤220 |

8.0 |

≤301 |

One-sided processing to 22.5 |

≤540 |

Table 4:Electrical strength of phenolic cotton fabric laminates

| Average thickness(mm) |

Electrical Strength(kV/mm) |

Average thickness(mm) | Electrical Strength(kV/mm) | Average thickness(mm) | Electrical Strength(kV/mm) |

|

0.8 |

≥0.89 |

1.6 |

≥0.72 |

2.6 |

≥0.56 |

|

0.9 |

≥0.84 |

1.8 |

≥0.69 |

2.8 |

≥0.53 |

|

1.0 |

≥0.82 |

2.0 |

≥0.65 |

3.0 |

≥0.50 |

|

1.2 |

≥0.80 |

2.2 |

≥0.61 |

||

|

1.4 |

≥0.76 |

2.4 |

≥0.58 |

Technical Features: Product Safety Control

Safety remains our best need all through the fabricating handle. We actualize comprehensive quality affirmation conventions including:

- Raw fabric review and verification

- In-process checking of temperature and weight parameters

- Final item testing for mechanical and electrical properties

- Dimensional precision verification

- Surface quality assessment

Our Phenolic Glass Laminates experience thorough testing strategies to guarantee they meet all security necessities for mechanical applications.

Product Application

These flexible materials discover applications over various industries:

Electrical Hardware: Protection auxiliary components, switchgear boards, transformer parts

Mechanical Frameworks: Gears, bearing shells, bushings, shims, and wear-resistant components

Motor Applications: Protection boundaries, mounting brackets, and basic supports

Furniture Industry: Enriching tea tables and other domestic outfitting components

Industrial Apparatus: Custom manufactured parts requiring electrical cover and mechanical strength

The great machinability characteristics make these covers perfect for custom applications requiring exact measurements and particular shapes.

OEM Service

We give comprehensive OEM administrations to meet your particular requirements:

- Custom thickness and dimensions

- Tailored mechanical properties

- Specialized surface treatments

- Custom packaging solutions

- Technical support throughout the design process

Our experienced building group works closely with clients to create arrangements that meet correct determinations. Whether you require standard items or custom definitions, we provide quality results.

Certification

FAQ

Q: What thickness options are available?

A: We offer thicknesses ranging from 2mm to 100mm to accommodate various application requirements.

Q: Can these materials be machined easily?

A: Yes, our phenolic laminates can be cut, drilled, and ground using standard machining tools and techniques.

Q: What are the fundamental contrasts between grades 3025 and 3026?

A: Both grades offer great execution, with particular property varieties suited to diverse application prerequisites. Contact our specialized group for point by point specifications.

Q: What bundling choices are available?

A: Standard bundling incorporates defensive bed bundling reasonable for sea, arrive, and discuss transportation.

Q: What is the typical lead time for orders?

A: Lead times vary based on order quantity and specifications. Contact us for current delivery schedules.

Contact Us

Ready to talk about your phenolic cover prerequisites? Our specialized specialists are here to offer assistance you select the right materials for your applications. We give point by point specialized information sheets, tests, and designing bolster to guarantee venture success.

For more information about our Phenolic Glass Laminates and other composite materials, please reach out to our team.

Email: info@jhd-material.com

Let us offer assistance you discover the culminate arrangement for your protection fabric needs. Contact us nowadays for competitive estimating and specialized determinations.

Send Inquiry

You May Like

0