Phenolic Paper Laminates

Basic Information:

Brand: JingHong

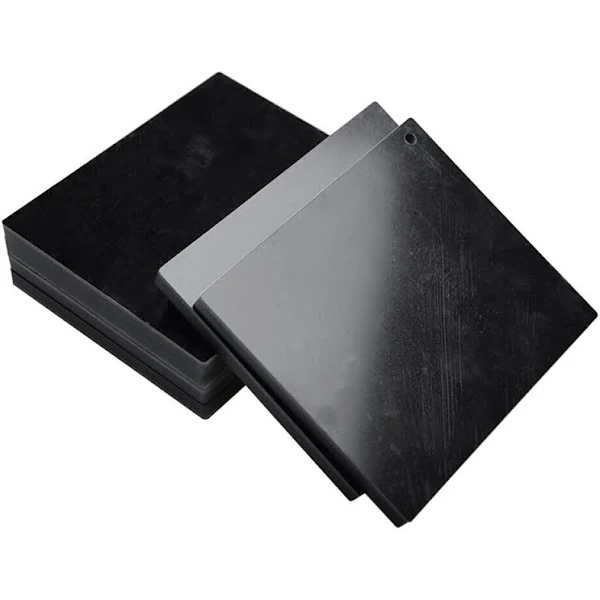

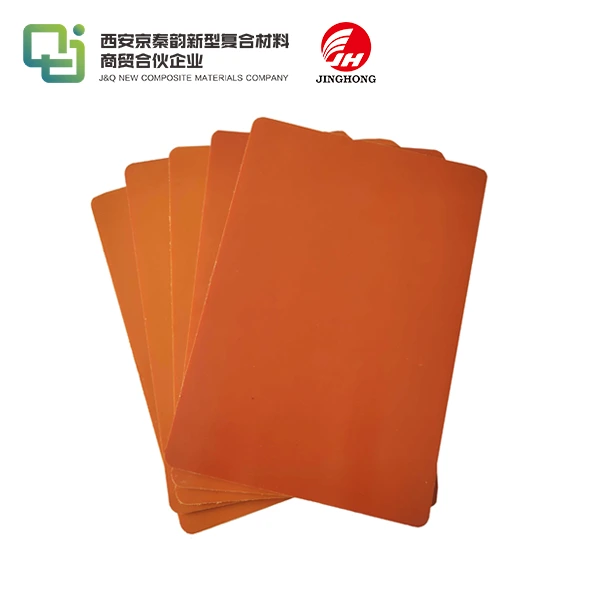

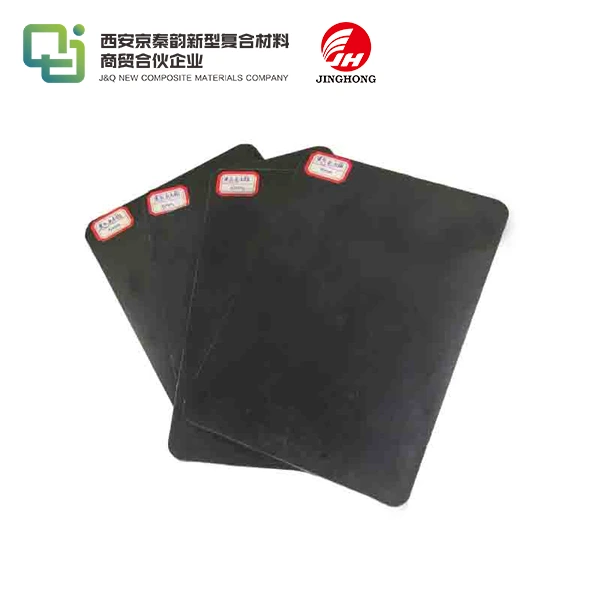

Materials: Wood Fiber Impregnated Insulating Paper + Phenolic Resin

Nature Color: Black and Orange

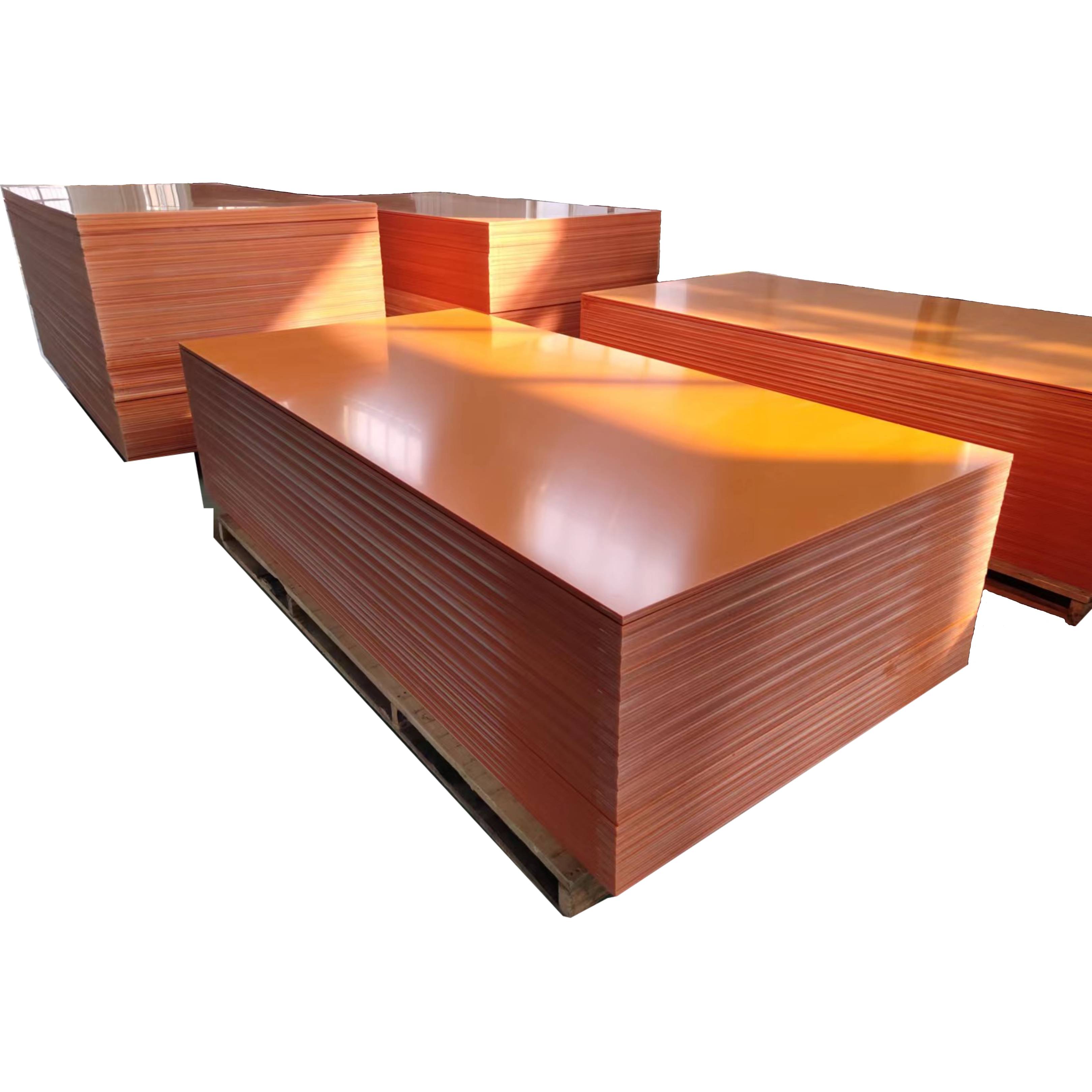

Thickness: 2mm --- 100mm

Regular Size: 1040mm*2080mm,1220mm*2200mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

High-Quality Phenolic Paper Laminates for Industrial Applications

Product Description from the Supplier

Our premium Phenolic Paper Laminates combine prevalent execution with extraordinary strength. Made by JingHong beneath J&Q Modern Composite Fabric Bunch, these covers include wood fiber impregnated protection paper fortified with phenolic tar. This one of a kind composition conveys extraordinary mechanical quality and warm resistance for requesting applications. You'll discover our materials idealize for electrical separator, mechanical components, and mechanical manufacture projects.

Description

Our phenolic covers offer extraordinary flexibility for different mechanical needs. The combination of characteristic wood strands and progressed phenolic gum makes a strong fabric that keeps up steadiness beneath extraordinary conditions. You can depend on these covers for reliable execution in challenging environments.

The fabricating handle guarantees uniform thickness and prevalent holding between layers. This comes about in materials that stand up to delamination and keep up auxiliary judgment over time. Your ventures advantage from decreased support costs and amplified benefit life.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Materials | Wood Fiber Impregnated Insulating Paper + Phenolic Resin |

| Available Colors | Black, Orange |

| Thickness Range | 2mm to 100mm |

| Standard Sizes | 1040mm × 2080mm, 1220mm × 2200mm, 1220mm × 2440mm |

| Production Capacity | 30,000 tons annually |

| Minimum Order | 500KG |

| Payment Terms | T/T (Telegraphic Transfer) |

| Shipping Options | Ocean, Land, Air transport |

Key Features

Superior Tensile Strength

Our materials accomplish 119MPa pliable quality, guaranteeing dependable execution beneath mechanical stress.

Excellent Thermal Performance

Continuous operation temperatures from 105°C to 140°C, with short-term resistance up to 300°C.

Chemical Resistance

Outstanding resistance to natural solvents, weaken acids, and frail alkalis.

Moisture Protection

Non-absorbent surface avoids dampness harm and keeps up electrical properties.

Dimensional Stability

Minimal development and compression over temperature ranges.

Standards

Our phenolic paper sheets comply with universal quality guidelines for electrical protection materials. The fabricating handle takes after strict quality control conventions to guarantee steady fabric properties. Each bunch experiences comprehensive testing for mechanical, warm, and electrical characteristics.

Technical Features: Product Safety Control

Quality Assurance Process:

- Raw fabric assessment and approval

- In-process observing amid lamination

- Final item testing for all specifications

- Batch following and documentation

Safety Features:

- Low smoke outflow amid warm exposure

- Self-extinguishing properties

- Non-toxic beneath typical working conditions

- Consistent electrical cover properties

Product Applications

Electrical Industry

Perfect for transformer cover, switchgear components, and electrical boards. The excellent dielectric properties make these Phenolic Paper Laminates ideal for high-voltage applications.

Mechanical Engineering

Suitable for gears, heading, and basic components requiring chemical resistance and dimensional stability.

Automotive Sector

Used in brake linings, clutch facings, and warm shields where warm resistance is critical.

Industrial Equipment

Excellent choice for pump components, valve seats, and chemical handling equipment.

OEM Service

We give comprehensive customization administrations to meet your particular necessities. Our specialized group works closely with you to create materials that coordinate your correct details. Custom measuring, thickness varieties, and uncommon definitions are accessible upon request.

Customization Options:

- Special measurements past standard sizes

- Modified gum formulations

- Custom bundling solutions

- Technical bolster and consultation

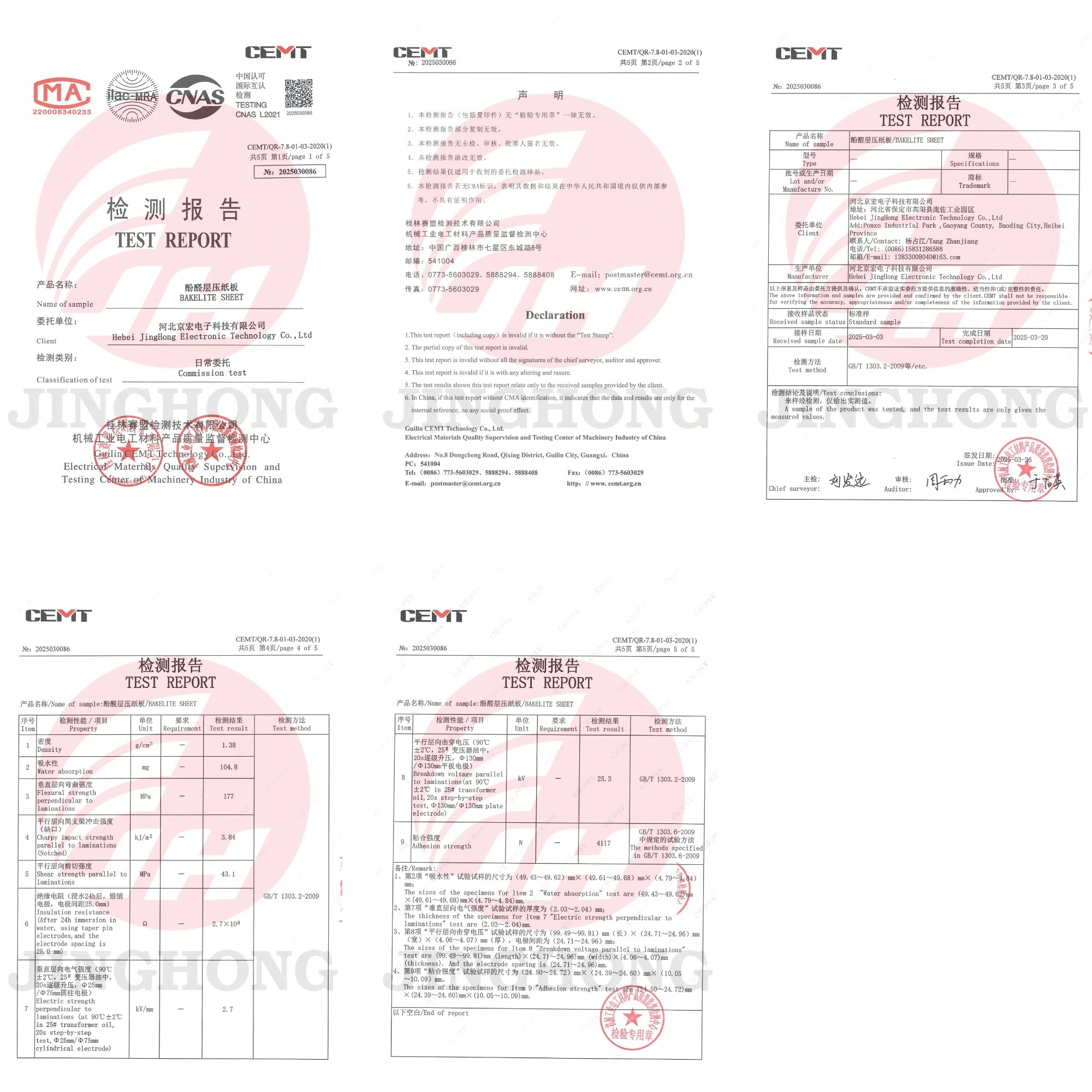

Certification

FAQ

Q: What is the most extreme working temperature for persistent use?

A: Our materials bolster nonstop operation between 105°C to 140°C, with short-term resistance up to 300°C.

Q: Can these covers be machined?

A: Yes, they machine effortlessly with standard carpentry and metalworking devices. Carbide-tipped apparatuses give the best results.

Q: What electrical properties can I expect?

A: These materials offer amazing dielectric quality and moo electrical conductivity, making them appropriate for electrical separator applications.

Q: How ought to I store these materials?

A: Store in a dry, cool environment absent from coordinate daylight. Appropriate capacity keeps up fabric properties for amplified periods.

Q: Are custom definitions available?

A: Yes, we can adjust tar substance and added substances to meet particular execution necessities for your applications.

Contact Us

Ready to enhance your projects with high-quality Phenolic Paper Laminates? Our technical team is here to help you select the right materials for your specific needs. We provide detailed technical specifications, samples, and application guidance to ensure optimal results.

Get in touch today:

Email: info@jhd-material.com

Whether you require standard sizes or custom arrangements, we're committed to conveying materials that surpass your desires. Contact us for cites, specialized bolster, or to examine your particular prerequisites with our experienced group.

Send Inquiry