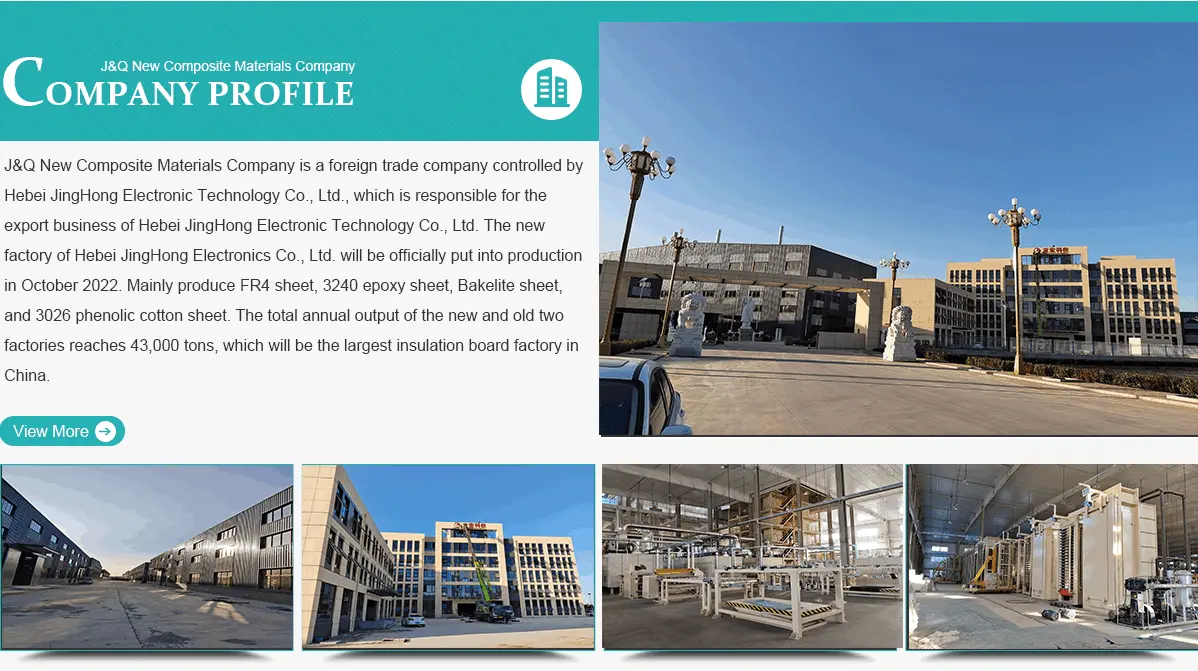

3240 Epoxy Glass Cloth Laminated Sheet Insulation Sheet

Basic Information:

Brand: JingHong

Materials: Alkali-free Cloth/medium-alkali Cloth + Epoxy Resin

Nature Color: Yellow

Thickness: 0.5mm --- 100mm

Size: 1020mm*2020mm (Regular)

Grade: A,B+,SR,B

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

3240 Epoxy Glass Cloth Laminated Sheet Insulation Sheet - Premium Electrical Insulation Solution

Our 3240 Epoxy Glass Cloth Laminated Sheet Insulation Sheet conveys extraordinary execution for your electrical and electronic applications. This premium cover fabric combines alkali-free glass cloth with high-quality epoxy tar, giving prevalent mechanical quality and electrical properties. With fabulous dimensional steadiness and dampness resistance, this item guarantees long-lasting execution in the most challenging environments

|

|

|

Product Description from JingHong

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Materials | Alkali-free Cloth / Medium-alkali Cloth + Epoxy Resin |

| Color | Natural Yellow |

| Thickness Range | 0.5mm - 100mm |

| Standard Size | 1020mm × 2020mm |

| Available Grades | A, B+, SR, B |

Our fabricating office produces 30,000 tons yearly, guaranteeing reliable supply for your ventures. We offer adaptable transportation alternatives counting sea, arrive, and discuss shipping to meet your conveyance requirements.

Product Availability

- Minimum Arrange Amount: 500KG

- Payment Terms: T/T (Transmitted Transfer)

- Packaging: Normal defensive bundling with bed protection

- Lead Time: Contact our group for current availability

- Custom Sizes: Accessible upon request

Key Features

Superior Dimensional Stability

Our epoxy glass cloth covered sheets keep up uncommon shape maintenance with curing shrinkage rates underneath 2%. This guarantees your components fit flawlessly each time.

Excellent Machinability

You can effortlessly cut, penetrate, and machine these sheets into different shapes for custom cover components. This adaptability spares you time and decreases generation costs.

Moisture Resistance

The cured epoxy gum framework stands up to dampness entrance, making it idealize for transformer oil-filled situations and clammy areas like marine electrical systems.

Mold Resistance

Our 3240 Epoxy Glass Cloth Laminated Sheet Insulation Sheet stands up to most molds and performs dependably indeed in cruel tropical conditions.

Standards

Our items meet universal electrical separator measures, guaranteeing compliance with industry necessities. The glass cloth fortification gives upgraded mechanical properties whereas keeping up great electrical characteristics.

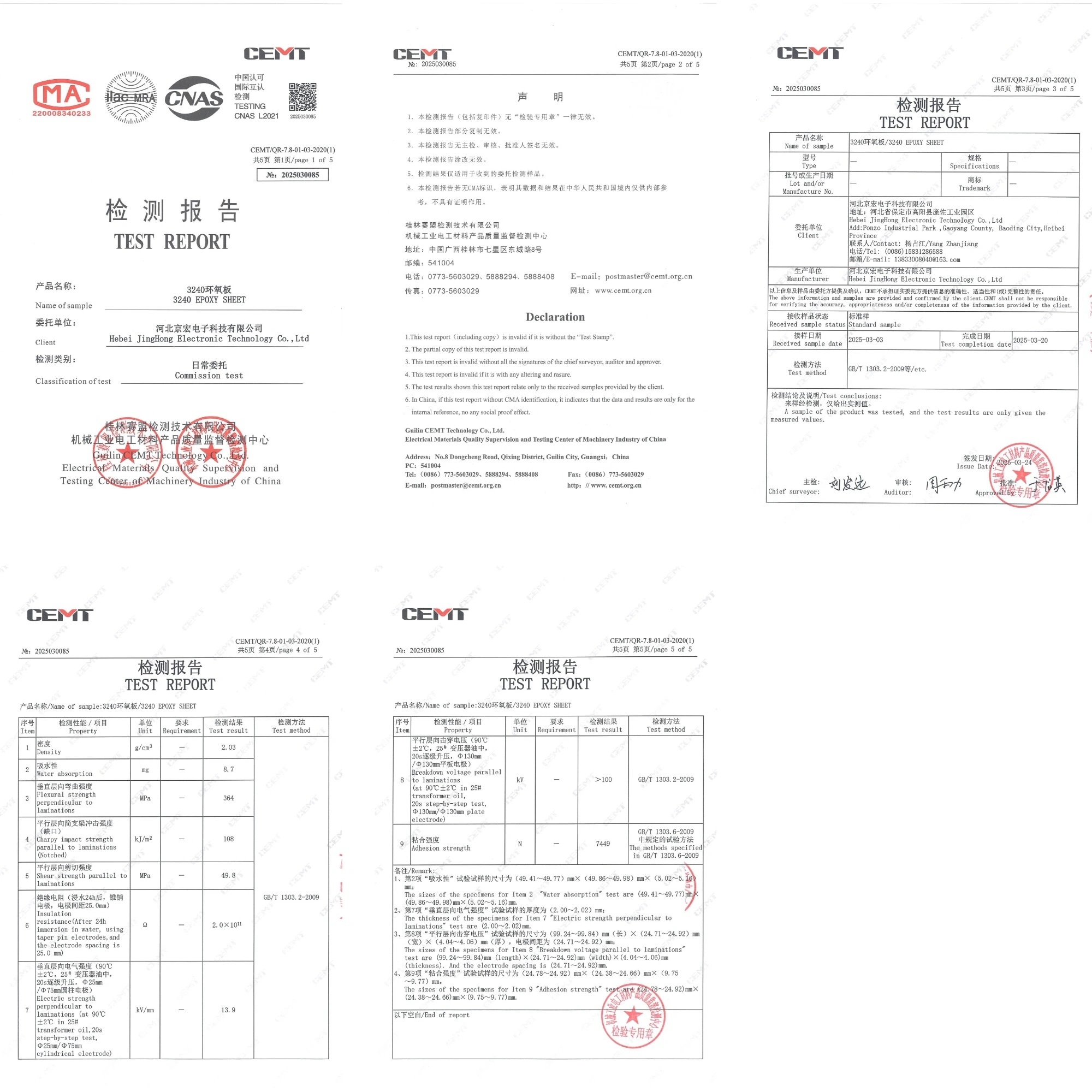

Technical Data for 3240 GradeB

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

|

1 |

Density |

g/cm3 |

2.07 |

GB/T 1303.2-2009 |

|

|

2 |

Water Absorption |

mg |

6.0 |

||

|

3 |

Bending Strength Perpendicular to Laminations |

A |

MPa |

203 |

|

|

B |

192 |

||||

|

4 |

Modulus of Elasticity in Flexure |

A |

MPa |

2.12*104 |

|

|

B |

2.38*104 |

||||

|

5 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

A |

KJ/m² |

47.4 |

|

|

B |

35.8 |

||||

|

6 |

Parallel Layer Shear Strength |

A |

MPa |

49.8 |

|

|

B |

52.7 |

||||

|

7 |

Tensile Strength |

A |

MPa |

147 |

|

|

B |

121 |

||||

|

8 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

438 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.0*109 |

||

|

10 |

Vertical Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

MV/m |

8.6 |

||

|

11 |

Parallel Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

kV |

28.0 |

||

|

12 |

Flammability |

- |

V-1 |

||

|

13 |

Deflection Temperature under Load |

A |

℃ |

>140 |

|

|

B |

>140 |

||||

|

14 |

Adhesive Strength |

N |

6324 |

GB/T 1303.6-2009 |

|

|

REMARK: 1. NO.2 the sample size is 50mm*50mm*50mm; 2. NO.8 the sample height is (9.05~9.56) mm; 3. NO.10 the sample thickness is (2.91~2.95)mm; 4. NO.11 the sample size is 100.00mm*5.08mm*24.10mm; |

|||||

Technical Features: Product Safety Control

Quality Assurance Process:

- Raw fabric review upon arrival

- In-process quality checking amid manufacturing

- Final item testing some time recently shipment

- Dimensional precision verification

- Electrical property validation

Safety Features:

- Non-toxic cured gum system

- Stable execution over temperature ranges

- Consistent electrical properties

- Fire-resistant characteristics

Product Applications

Power Generation Equipment

Ideal for transformer components, generator parts, and switchgear cover where solid execution is critical.

Marine Electronics

Perfect for shipboard electrical frameworks where dampness resistance and dimensional solidness are basic requirements.

Industrial Machinery

Excellent choice for engine separator, control board components, and mechanical mechanization equipment.

Telecommunications

Suitable for communication hardware lodgings and circuit board applications requiring predominant electrical insulation.

OEM Service

We get it that your applications may require particular measurements or properties. Our experienced designing group works closely with you to create custom arrangements. Whether you require extraordinary thicknesses, interesting sizes, or adjusted properties, we can adjust our item to meet your correct specifications.

Our OEM services include:

- Custom measuring and thickness options

- Modified tar formulations

- Special bundling requirements

- Technical bolster all through your project

Certification

J&Q Unused Composite Fabric Gather Co., Ltd keeps up strict quality control frameworks. Our fabricating forms take after worldwide quality guidelines to guarantee steady item execution and reliability.

Frequently Asked Questions

Q: What makes your epoxy glass cloth sheets different from competitors?

A: Our sheets highlight predominant dimensional soundness with less than 2% shrinkage and great dampness resistance, making them perfect for requesting applications.

Q: Can you provide custom thicknesses outside the standard range?

A: Yes, we can fabricate custom thicknesses to meet your particular prerequisites. It would be ideal if you contact us with your specifications.

Q: How does this material perform in high-humidity environments?

A: Our item performs perfectly in sticky conditions without debasement, making it culminate for marine and tropical applications.

Q: What is the typical lead time for orders?

A: Lead times change based on amount and details. Contact us for current accessibility and conveyance schedules.

Q: Do you offer technical support for application development?

A: Completely! Our specialized group gives comprehensive back to offer assistance you select the right review and details for your application.

Contact Us

Ready to talk about your cover fabric prerequisites? Our specialized specialists are here to offer assistance you discover the idealize arrangement for your application.

Email: info@jhd-material.com

Contact us today to learn more about our 3240 Epoxy Glass Cloth Laminated Sheet Insulation Sheet materials and how they can improve your product performance. We look forward to partnering with you on your next project.

Send Inquiry

_1764655473125.jpg)

_1764655473256.jpg)