Electrical Insulation Epoxy Plastic 3240 Sheet

Basic Information:

Brand: JingHong

Materials: Alkali-free Cloth/medium-alkali Cloth + Epoxy Resin

Nature Color: Yellow

Thickness: 0.5mm --- 100mm

Size: 1020mm*2020mm (Regular)

Grade: A,B+,SR,B

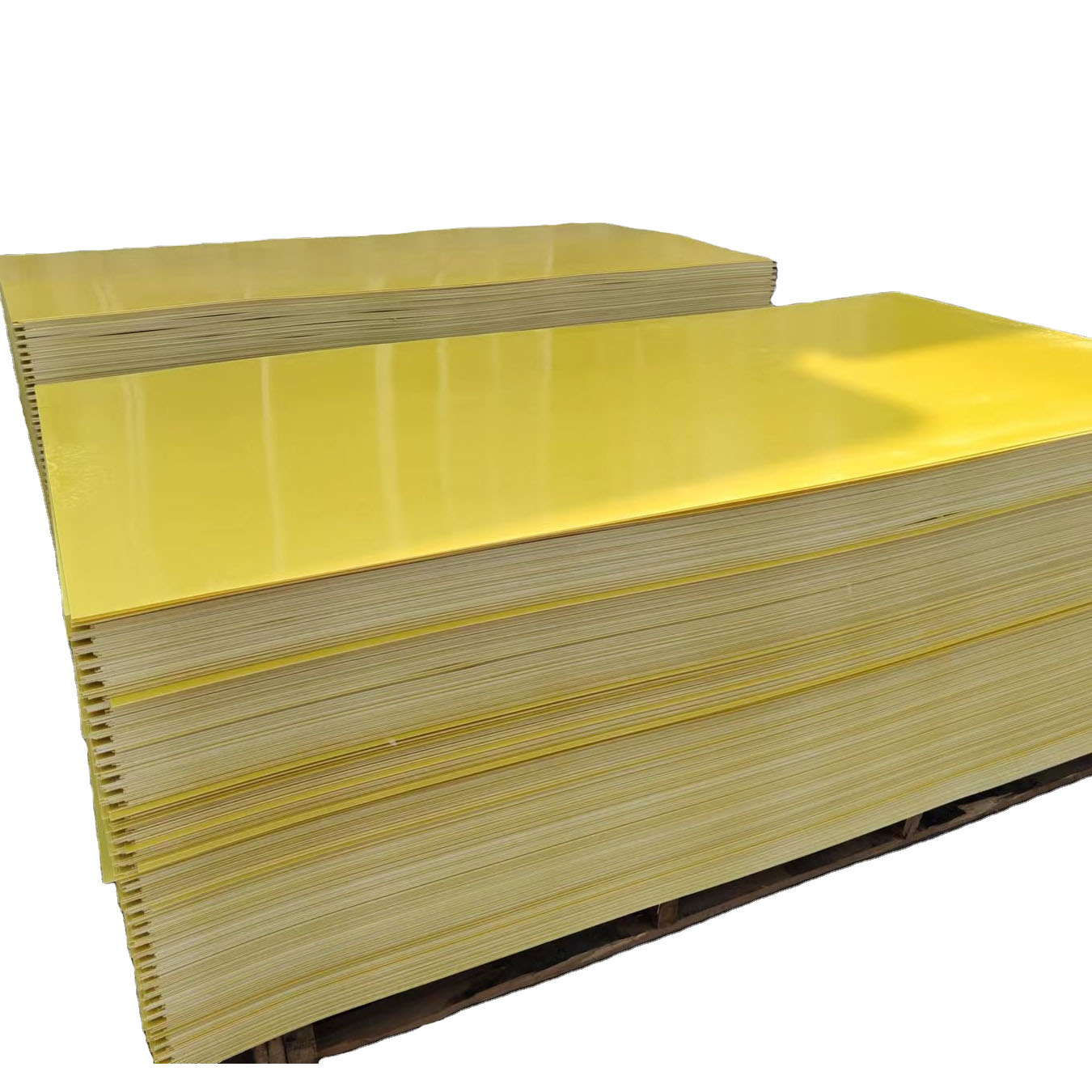

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Electrical Insulation Epoxy Plastic 3240 Sheet - Premium Insulating Solution

Our Electrical Insulation Epoxy Plastic 3240 Sheet offers predominant execution and extraordinary strength. Made from high-quality alkali-free cloth and premium epoxy gum, this fabric gives extraordinary electrical properties. Whether you require cover for transformers, engines, or electrical boards, our 3240 sheets convey steady comes about. Accessible in different thicknesses and grades, these sheets meet assorted mechanical necessities with dependable execution you can trust.

Product Descriptions from the Supplier

J&Q New Composite Materials Company gladly presents our JingHong brand 3240 epoxy sheets. These premium protection materials combine alkali-free cloth with progressed epoxy gum innovation. The normal yellow color demonstrates bona fide fabric composition.

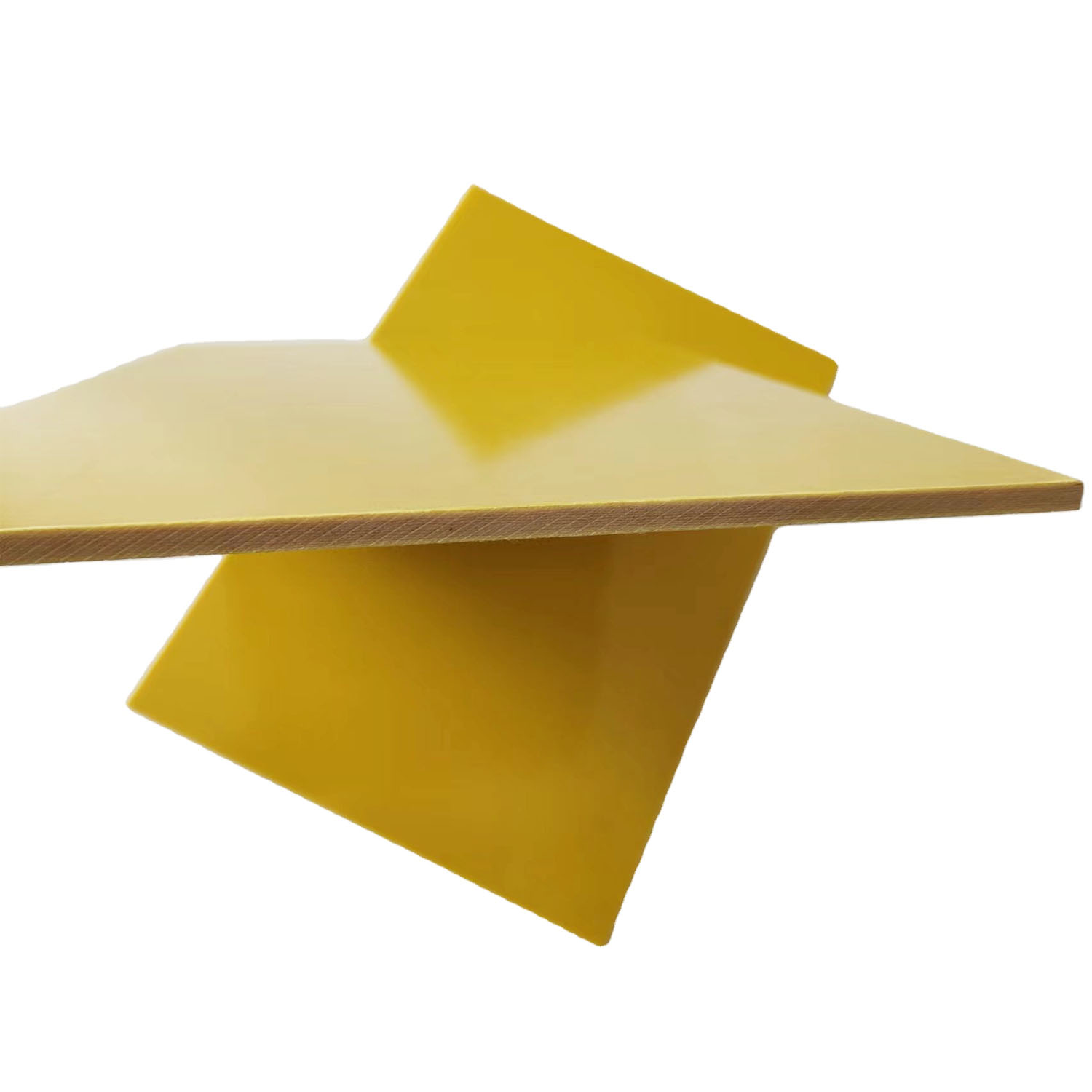

Our fabricating prepare guarantees uniform thickness dissemination from 0.5mm to 100mm. Each sheet keeps up reliable quality all through its whole surface range. The standard measure of 1020mm×2020mm suits most mechanical applications efficiently.

Description

This progressed composite fabric highlights remarkable electrical separator properties. The alkali-free cloth base gives mechanical quality whereas epoxy gum conveys prevalent electrical characteristics. Together, they make a fabric culminate for requesting electrical environments.

The fabricating handle includes cautious impregnation of glass cloth with epoxy tar. After legitimate curing, the result is a thick, void-free fabric. This handle guarantees ideal execution in electrical applications.

Product Availability

We keep up considerable stock to meet your prompt needs. Our generation capacity comes to 30,000 tons every year, guaranteeing steady supply. Accessible grades incorporate A, B+, SR, and B to coordinate particular application requirements.

Minimum arrange amount begins at 500KG, making it open for both huge and medium-scale ventures. Customary pressing secures materials amid transportation. Bed assurance guarantees secure conveyance to your facility.

Key Features

Superior Electrical Properties: Cover resistance ranges from 10¹⁴ to 10¹⁶ Ω·cm, giving uncommon electrical isolation.

Chemical Resistance: Amazing resistance to acids, antacids, and natural solvents guarantees long-term execution in cruel environments.

Mechanical Quality: Tall malleable quality and affect resistance keep up auxiliary astuteness beneath stress.

Temperature Steadiness: Performs reliably over wide temperature ranges without property degradation.

Arc Resistance: Extraordinary bend resistance anticipates electrical following and keeps up safety.

Dimensional Soundness: Negligible warm extension guarantees exact fit in electrical assemblies.

Standards

Our materials comply with worldwide electrical cover benchmarks. Quality control strategies take after strict rules all through generation. Each bunch experiences comprehensive testing some time recently shipment.

Testing incorporates electrical breakdown voltage, cover resistance, and mechanical quality confirmation. Chemical resistance testing guarantees materials meet indicated execution criteria.

Technical Data for 3240 GradeB

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

|

1 |

Density |

g/cm3 |

2.07 |

GB/T 1303.2-2009 |

|

|

2 |

Water Absorption |

mg |

6.0 |

||

|

3 |

Bending Strength Perpendicular to Laminations |

A |

MPa |

203 |

|

|

B |

192 |

||||

|

4 |

Modulus of Elasticity in Flexure |

A |

MPa |

2.12*104 |

|

|

B |

2.38*104 |

||||

|

5 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

A |

KJ/m² |

47.4 |

|

|

B |

35.8 |

||||

|

6 |

Parallel Layer Shear Strength |

A |

MPa |

49.8 |

|

|

B |

52.7 |

||||

|

7 |

Tensile Strength |

A |

MPa |

147 |

|

|

B |

121 |

||||

|

8 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

438 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.0*109 |

||

|

10 |

Vertical Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

MV/m |

8.6 |

||

|

11 |

Parallel Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

kV |

28.0 |

||

|

12 |

Flammability |

- |

V-1 |

||

|

13 |

Deflection Temperature under Load |

A |

℃ |

>140 |

|

|

B |

>140 |

||||

|

14 |

Adhesive Strength |

N |

6324 |

GB/T 1303.6-2009 |

|

|

REMARK: 1. NO.2 the sample size is 50mm*50mm*50mm; 2. NO.8 the sample height is (9.05~9.56) mm; 3. NO.10 the sample thickness is (2.91~2.95)mm; 4. NO.11 the sample size is 100.00mm*5.08mm*24.10mm; |

|||||

Technical Features: Product Safety Control

Safety remains our beat need all through fabricating and application. Our Electrical Insulation Epoxy Plastic 3240 Sheet experiences thorough quality control testing. Each generation bunch gets electrical property confirmation some time recently shipment.

Material composition testing guarantees steady epoxy tar substance. Thickness estimations confirm dimensional exactness over whole sheet surfaces. Visual review recognizes any surface absconds that might influence performance.

Temperature cycling tests affirm warm solidness beneath working conditions. Chemical presentation testing approves resistance to mechanical chemicals and solvents.

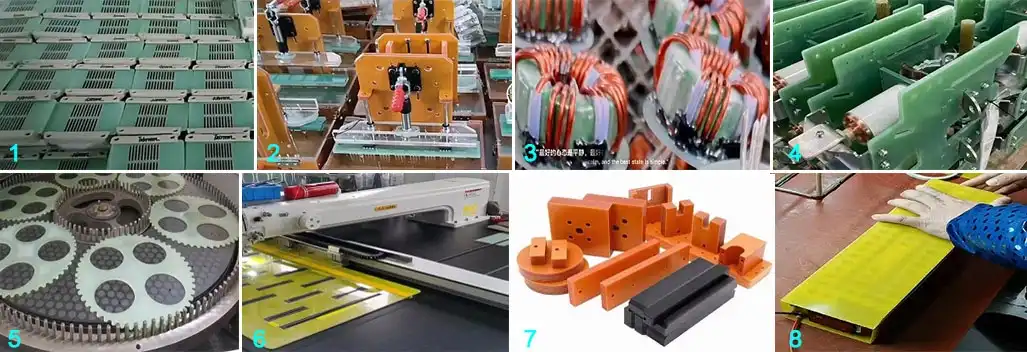

Product Application

These flexible sheets serve various electrical cover applications:

Transformer Components: Protection boundaries and basic bolsters in control transformers.

Motor Cover: Opening liners and stage separators in electric engines and generators.

Switchgear: Protection boards and obstructions in electrical switchboards and control panels.

Circuit Breakers: Circular segment chutes and protection underpins in high-voltage circuit breakers.

Industrial Gear: Electrical cover in fabricating gear and mechanization systems.

Power Conveyance: Protection components in electrical dispersion frameworks and substations.

OEM Service

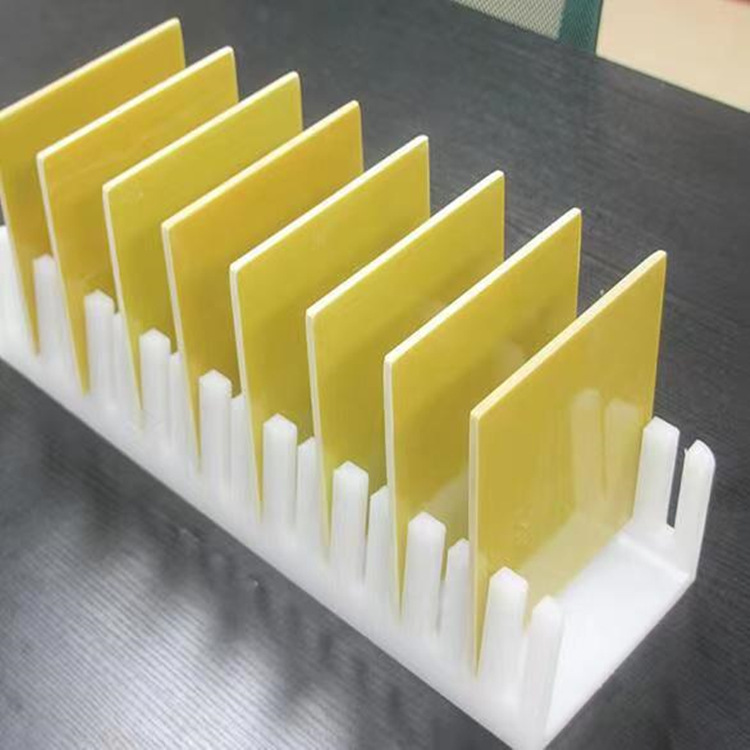

We give comprehensive OEM administrations custom-made to your particular prerequisites. Custom cutting administrations make exact measurements for your applications. Uncommon thickness necessities can be suited through our adaptable fabricating process.

Color customization alternatives are accessible for recognizable proof purposes. Custom bundling arrangements guarantee secure conveyance for your particular taking care of necessities. Specialized bolster helps with fabric determination and application guidance.

Our building group collaborates with you to optimize fabric properties for particular applications. This association approach guarantees ideal execution in your one of a kind working environment.

Certification

FAQ

Q: What thickness options are available for this material?

A: We offer thicknesses ranging from 0.5mm to 100mm to accommodate various application requirements.

Q: How does this material perform in high-temperature environments?

A: Our epoxy sheets maintain excellent electrical properties across wide temperature ranges with minimal degradation.

Q: Can you provide custom cutting services?

A: Yes, we offer precision cutting services to meet your specific dimensional requirements.

Q: What is the typical delivery time for orders?

A: Standard orders typically ship within 7-14 days, depending on quantity and customization requirements.

Q: Is technical support available for material selection?

A: Absolutely. Our technical team provides comprehensive support for material selection and application guidance.

Contact Us

Ready to enhance your electrical insulation solutions? Our Electrical Insulation Epoxy Plastic 3240 Sheet delivers the reliability and performance your projects demand.

Contact our specialized deals group nowadays for point by point determinations, estimating, and test demands. We're here to offer assistance you discover the idealize cover arrangement for your particular needs.

Email: info@jhd-material.com

Let us accomplice with you to accomplish prevalent electrical separator execution in your applications.

Send Inquiry

_1764659290325.jpg)