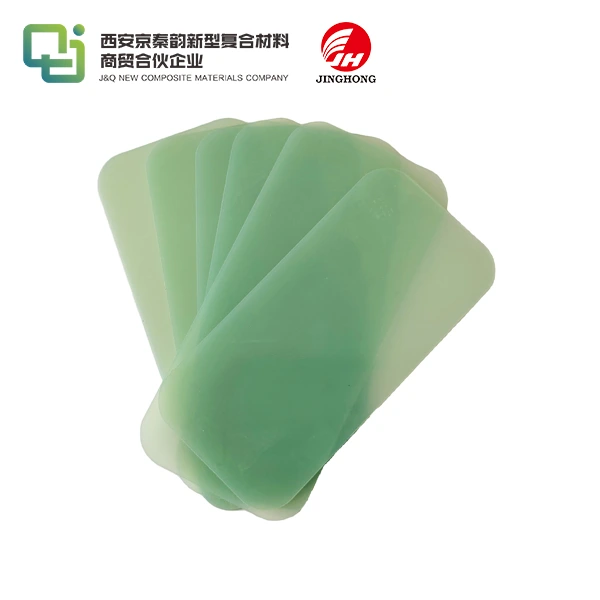

Fr-4 Flame Retardant Epoxy Resin Fiberglass Laminate Sheet

Basic Information:

Brand:JingHong

Materials: 7628 electronic cloth + Epoxy Resin

Grade: UL94V1,UL94V0,NEMA

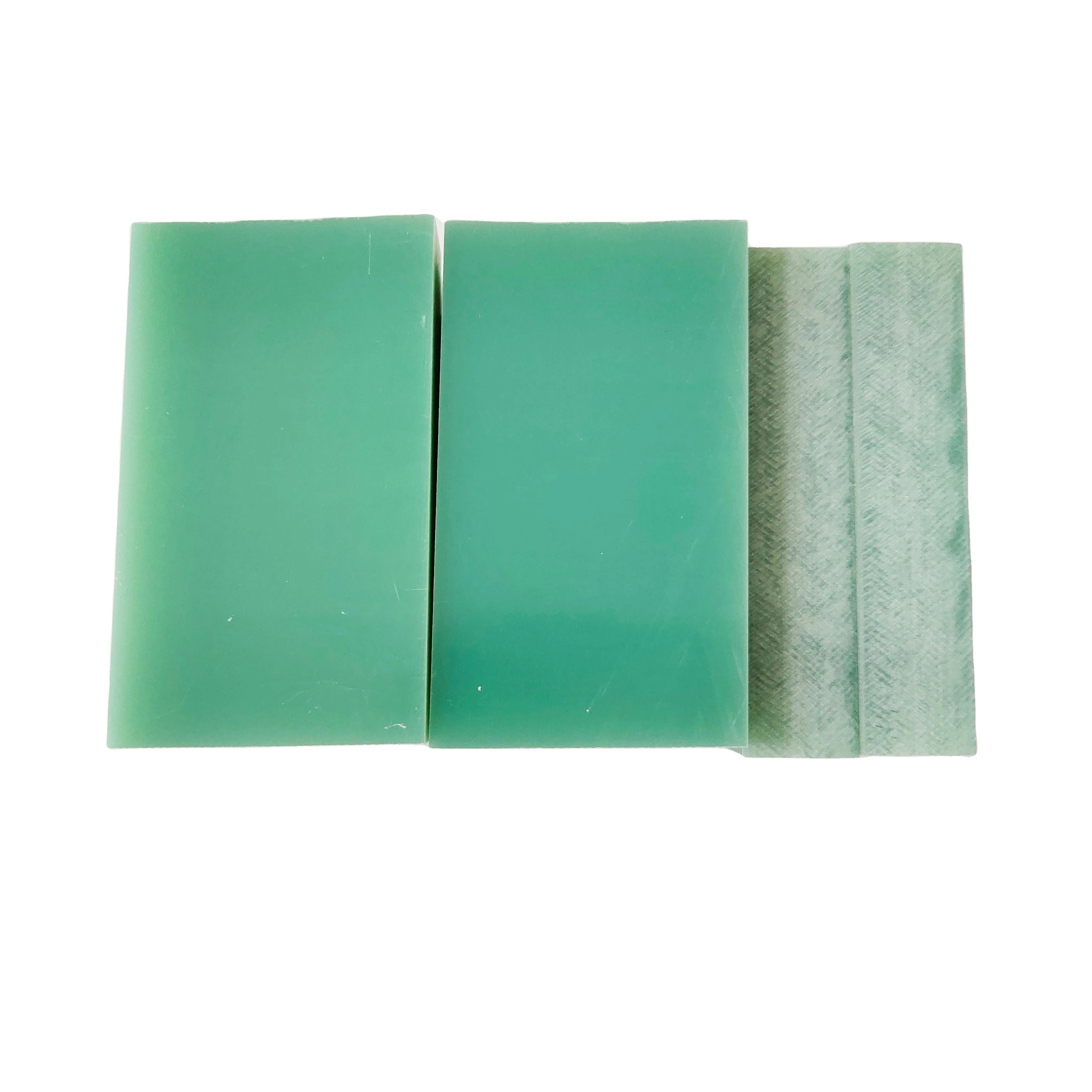

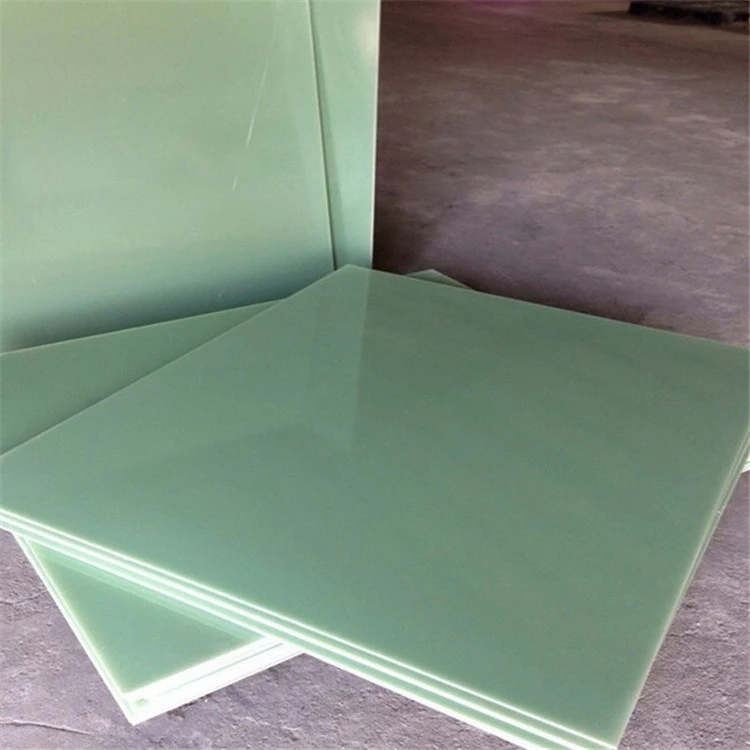

Nature Color: Light Green

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm,1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Fr-4 Flame Retardant Epoxy Resin Fiberglass Laminate Sheet

Product Description from the Supplier

Our Fr-4 Flame Retardant Epoxy Resin Fiberglass Laminate Sheet conveys extraordinary execution for your electronic applications. Made from premium 7628 electronic cloth and high-quality epoxy tar, this fabric offers predominant fire resistance and electrical properties. You can believe JingHong brand quality for your most requesting ventures. Our sheets give fabulous mechanical quality whereas keeping up steady electrical characteristics over different working conditions.

Description

Our Fr-4 cover sheets combine progressed fabric science with down to earth designing arrangements. The light green colored sheets highlight great dimensional soundness and moo dampness retention. You'll appreciate the reliable quality that comes from our carefully controlled fabricating handle. Each sheet experiences thorough testing to guarantee it meets worldwide guidelines for electrical and warm performance.

The epoxy gum lattice gives great attachment to the fiberglass fortification. This makes a composite fabric with exceptional strength-to-weight proportion. Your applications will advantage from the material's resistance to chemicals and natural conditions.

Product Availability

We maintain consistent inventory levels to meet your project timelines.

| Specification | Details |

|---|---|

| Standard Sizes | 1020mm × 1220mm,1220mm × 2440mm,1220mm × 2440mm |

| Custom Dimensions | 1030mm × 2030mm,1030mm × 1030mm,1030mm × 2070mm |

| Thickness Options | 0.3mm to 100mm |

| Minimum Order Quantity | 500KG |

| Annual Production Capacity | 30,000 tons |

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Key Features

Superior Fire Resistance: UL94V0 and V1 evaluations guarantee security in basic applications

Excellent Electrical Properties: Dielectric steady of 5.0-5.5 with moo misfortune tangent

Dimensional Soundness: Warpage controlled inside 3mm for standard sizes

Versatile Thickness Run: Accessible from 0.3mm to 100mm

Premium Materials: 7628 electronic cloth fortification with epoxy tar matrix

Custom Measuring: Adaptable measurements to meet particular extend requirements

Standards

Our materials comply with NEMA standards for electrical insulation. The Fr-4 Flame Retardant Epoxy Resin Fiberglass Laminate Sheet meets UL94 fire retardancy necessities at both V0 and V1 levels. These certifications guarantee your items meet security controls in different markets.

International quality guidelines direct our fabricating forms. Each group experiences comprehensive testing for electrical, mechanical, and warm properties. You get materials that reliably perform to specification.

Technical Features: Product Safety Control

Safety remains our beat need all through generation and conveyance. Our quality control framework screens each arrange from crude fabric assessment to last bundling. Temperature and stickiness conditions are carefully controlled amid fabricating to guarantee ideal curing.

Electrical testing confirms dielectric quality and cover resistance values. Fire retardancy testing affirms UL94 compliance for each generation part. Mechanical testing approves ductile quality and flexural properties. These comprehensive checks ensure you get materials assembly all indicated requirements.

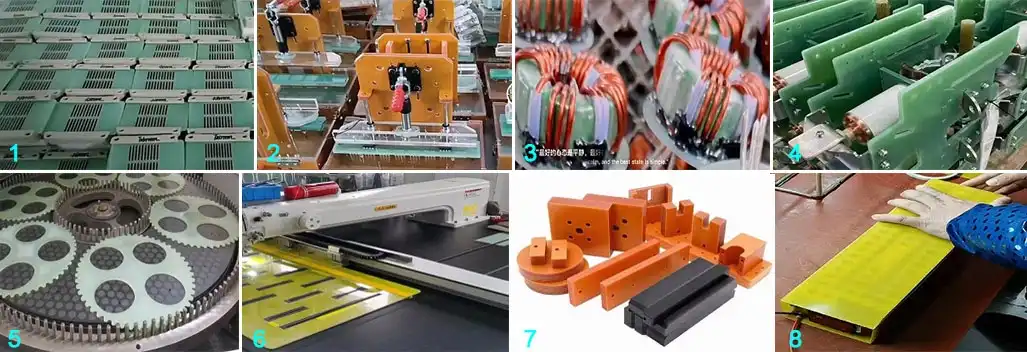

Product Application

Circuit board substrates advantage from the fabulous electrical properties and dimensional steadiness. Electrical boards and switchgear components utilize these sheets for solid cover. Engine and generator applications depend on the warm resistance and mechanical strength.

Aerospace and car businesses select this fabric for weight-sensitive applications. Mechanical gear producers appreciate the chemical resistance and solidness. Test installations and dances keep up exactness due to the moo warm development characteristics.

OEM Service

We get it that your applications may require particular alterations. Our designing group works with you to create custom arrangements. Whether you require extraordinary thicknesses, special measurements, or adjusted properties, we can adjust our fabricating process.

Technical back proceeds all through your item advancement cycle. Our specialists give direction on fabric choice and application strategies. This collaborative approach guarantees ideal execution in your last products.

FAQ

Q: What is the typical lead time for standard sizes?

A: Standard sizes are usually available within 2-3 weeks from order confirmation.

Q: Can you provide smaller quantities for prototyping?

A: Yes, we can accommodate smaller quantities above our 500KG minimum order.

Q: What packaging options are available?

A: We offer regular packaging with pallet protection and can customize packaging for specific shipping requirements.

Q: How do you ensure consistent quality?

A: Our comprehensive quality control system includes incoming material inspection, in-process monitoring, and final product testing.

Q: What transportation methods do you support?

A: We ship via ocean, land, and air transport depending on your location and urgency requirements.

Contact Us

Ready to discuss your Fr-4 Flame Retardant Epoxy Resin Fiberglass Laminate Sheet requirements? Our technical sales team stands ready to help you find the perfect solution for your application.

Email us at info@jhd-material.com for point by point determinations, estimating data, or specialized bolster. We react to all request inside 24 hours and give comprehensive item information to back your decision-making process.

Let us offer assistance you accomplish your venture objectives with solid, high-quality materials that meet your correct details.

Send Inquiry

_1764314369204.jpg)

_1764314369188.jpg)

拷贝_1755500211555.jpg)