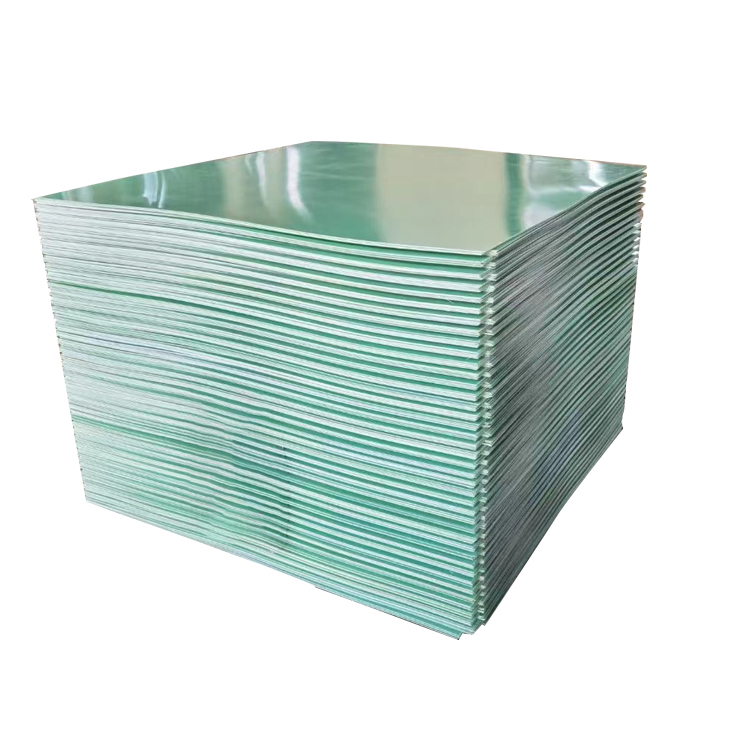

G10 Epoxy Glass Fiber Sheets G-10 Plates

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

G10 Epoxy Glass Fiber Sheets G-10 Plates

Our G10 Epoxy Glass Fiber Sheets G-10 Plates combine progressed 7628 electronic cloth with premium epoxy gum to make predominant composite materials. These high-strength plates offer exceptional electrical cover, mechanical toughness, and warm steadiness. Whether you require standard sizes or custom determinations, our G10 sheets meet the requesting necessities of electrical, electronic, and mechanical applications with reliable quality and performance.

Description

G10 epoxy glass fiber sheets speak to cutting-edge composite innovation. Made from woven glass texture impregnated with epoxy tar, these plates experience high-pressure cover to make thick, uniform materials. The result is extraordinary strength-to-weight proportion and amazing dimensional stability.

Our fabricating handle guarantees steady quality over all sheets. Each plate keeps up uniform thickness and surface wrap up. The controlled curing handle makes solid atomic bonds that stand up to delamination and cracking.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Materials | 7628 Electronic Cloth + Epoxy Resin |

| Available Colors | Light Green, Yellow, Black |

| Thickness Range | 0.3mm to 100mm |

| Standard Sizes | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Sizes | 1030mm × 2030mm, 1220mm × 2440mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Minimum Order | 500KG |

| Annual Capacity | 30,000 Tons |

Key Features

- Superior Electrical Cover: Volume resistivity of 2.0×10⁸MΩ gives great electrical protection

- Outstanding Bend Resistance: 135S rating guarantees solid execution in electrical applications

- High Mechanical Quality: Remarkable pliable and flexural quality for requesting applications

- Excellent Water Resistance: Moo dampness retention keeps up properties in muggy conditions

- Chemical Resistance: Withstands introduction to oils, solvents, and numerous chemicals

- Dimensional Solidness: Negligible development and compression over temperature ranges

- Easy Machining: Clean cutting, penetrating, and forming without delamination

Standards

Our G10 Epoxy Glass Fiber Sheets G-10 Plates meet international quality standards:

- Flame Retardant Review: UL94V0 for improved safety

- Complies with electrical cover fabric specifications

- Meets aviation and military review requirements

- Conforms to mechanical composite fabric standards

Technical Data for G10

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-1 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

You can believe our comprehensive quality control framework. Each bunch experiences thorough testing for electrical properties, mechanical quality, and dimensional precision. Our quality group screens thickness consistency, surface quality, and fabric composition.

Temperature testing guarantees execution over working ranges. Electrical testing confirms cover properties and bend resistance. Mechanical testing affirms quality and toughness specifications.

We keep up traceability records for all materials. This guarantees reliable quality and empowers speedy reaction to any concerns.

Product Application

G10 plates serve different businesses and applications:

Electrical & Electronics:

- Circuit board substrates and supports

- Transformer and motor insulation

- Switchgear components

- Electrical enclosures

Industrial Manufacturing:

- Machining fixtures and jigs

- Wear strips and guides

- Chemical processing equipment

- Structural components

Specialized Applications:

- Knife handles and sporting goods

- Marine applications requiring water resistance

- Aerospace components

- Military equipment

OEM Service

We get it your special necessities. Our experienced group works with you to create custom arrangements. Whether you require particular measurements, colors, or execution characteristics, we can help.

Our building back incorporates fabric determination direction and application exhortation. We give specialized documentation and test information to back your projects.

Custom bundling alternatives ensure your materials amid shipping. We facilitate conveyance plans to meet your generation timelines.

FAQ

Q: What makes G10 suitable for knife handles?

A: G10 offers high strength, water resistance, corrosion resistance, and excellent grip characteristics. These properties make it ideal for long-term knife usage.

Q: Can G10 sheets be machined easily?

A: Yes, G10 machines cleanly with standard tools. It drills, cuts, and shapes without delamination when proper techniques are used.

Q: What's the temperature range for G10 materials?

A: G10 maintains properties from -50°C to +180°C, making it suitable for most industrial applications.

Q: How do you ensure consistent quality?

A: We implement comprehensive testing protocols including electrical, mechanical, and dimensional checks on every batch.

Q: What payment terms do you offer?

A: We accept T/T payment terms with flexible arrangements based on order size and customer requirements.

Contact Us

Ready to discuss your G10 Epoxy Glass Fiber Sheets G-10 Plates requirements? Our technical team is here to help you select the right materials for your application.

Email: info@jhd-material.com

Contact us nowadays for estimating, specialized details, or custom arrangements. We're committed to giving high-quality materials and extraordinary benefit for your extend victory.

Send Inquiry

You May Like

0