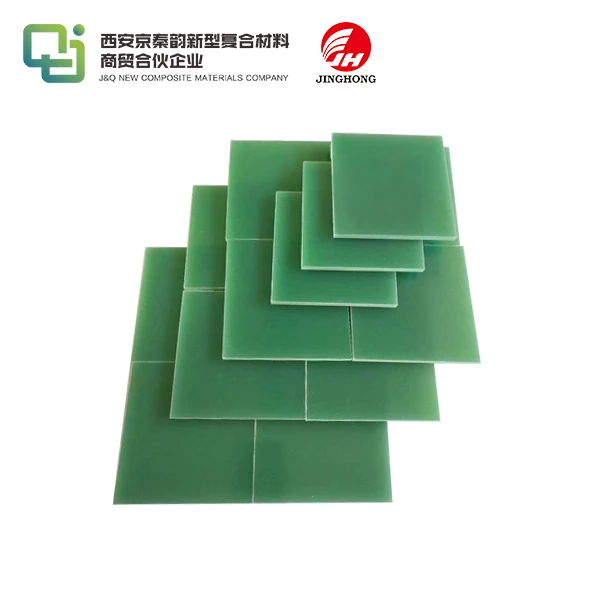

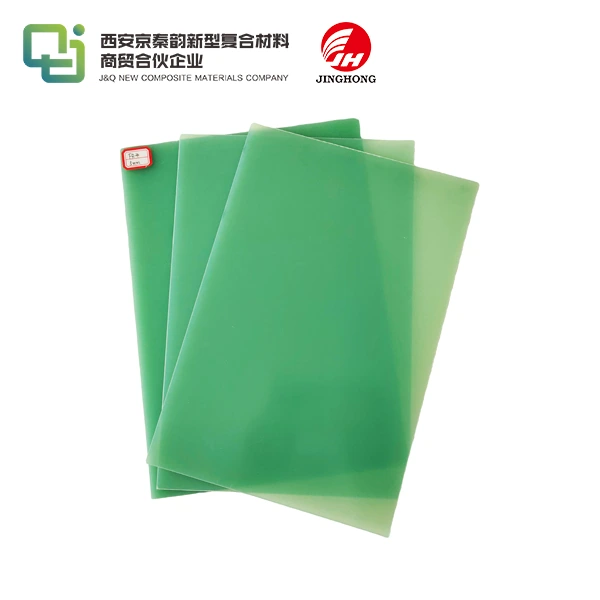

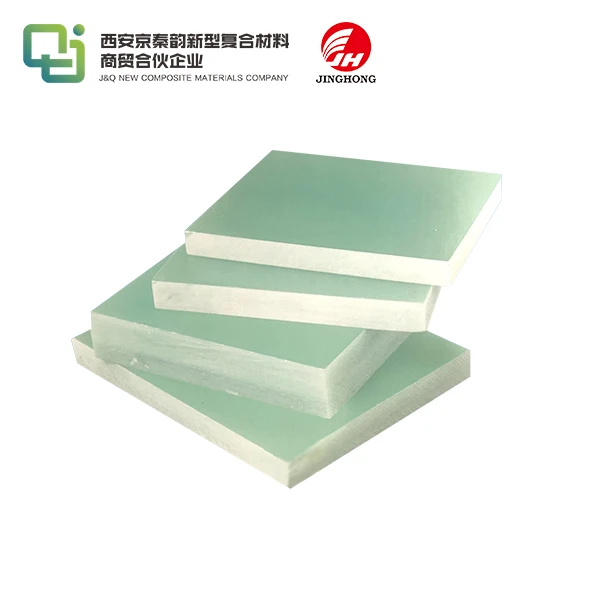

G-10 Glass Fiber Plates

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

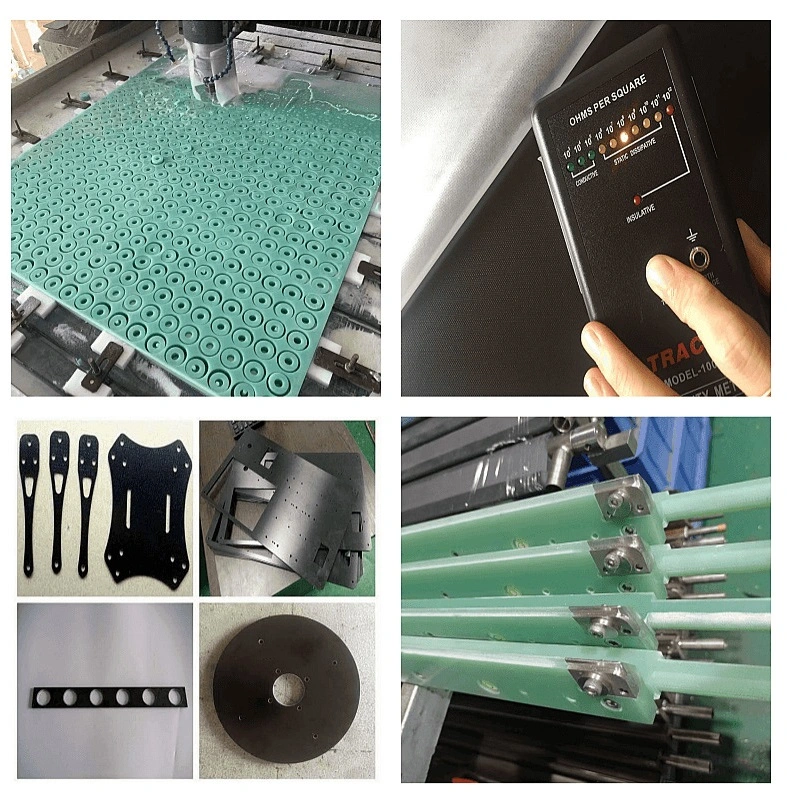

G-10 Glass Fiber Plates: High-Performance Composite Materials for Industrial Applications

Our G-10 Glass Fiber Plates convey uncommon execution and toughness. These progressed composite plates combine 7628 electronic cloth with premium epoxy gum to make materials that meet the most requesting mechanical necessities. Whether you require electrical cover, mechanical components, or auxiliary components, our glass fiber plates give the unwavering quality and execution your applications demand.

Description

Our fiber plates speak to the idealize combination of progressed materials science and commonsense designing. Made from high-quality 7628 electronic cloth and epoxy tar, these composite materials offer prevalent mechanical properties and great electrical cover characteristics. The fabricating prepare guarantees reliable quality and uniform thickness over each plate.

Each plate experiences thorough quality control testing to ensure ideal execution. The ceaseless fiber glass texture gives extraordinary quality, whereas the epoxy tar framework conveys chemical resistance and dimensional soundness. This combination makes materials that perform dependably in challenging environments.

Product Availability

We keep up broad stock to meet your venture timelines.

| Attribute | Details |

|---|---|

| Standard Sizes | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Dimensions Available | 1030mm × 2030mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Thickness Range | 0.3mm to 100mm |

| Available Colors | Light Green, Yellow, Black |

| Minimum Order Quantity | 500KG |

| Annual Production Capacity | 30,000 tons |

Key Features

Superior Mechanical Strength

Flexural quality comes to 1320-2200 N/cm², giving fabulous resistance to bowing powers and affect loads.

High Hardness Rating

Achieves 89-92 HRA hardness, guaranteeing fabulous wear resistance and dimensional stability.

Flame Retardant Properties

UL94V0 rating ensures prevalent fire security execution for basic applications.

Low Thermal Expansion

Linear development coefficient of 12×10⁻⁶/℃ guarantees dimensional steadiness over temperature variations.

Excellent Electrical Properties

Outstanding dielectric quality and cover resistance make these plates perfect for electrical applications.

Standards

Our G-10 Glass Fiber Plates fabricating forms comply with universal quality guidelines. Each bunch meets strict determinations for:

- Dimensional resilience control

- Surface wrap up requirements

- Mechanical property consistency

- Electrical execution standards

- Chemical resistance specifications

Quality confirmation conventions guarantee each plate meets or surpasses industry benchmarks for composite materials.

Technical Features: Product Safety Control

Material Composition Control

We carefully select premium 7628 electronic cloth and high-grade epoxy gum to guarantee steady fabric properties all through each plate.

Process Monitoring

Advanced fabricating controls keep up ideal curing conditions, weight application, and temperature profiles amid production.

Quality Testing

Comprehensive testing incorporates mechanical property confirmation, electrical execution assessment, and dimensional exactness measurement.

Safety Certifications

UL94V0 fire retardant rating guarantees secure operation in electrical and high-temperature environments.

Technical Data for G10

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-1 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Product Applications

Electrical Industry

Switchgear components, transformer parts, circuit breaker components, and electrical boards advantage from amazing dielectric properties.

Aerospace Applications

Structural components, brackets, and insides boards where weight diminishment and quality are basic requirements.

Marine Environments

Boat components, deck plates, and marine electrical walled in areas that require dampness resistance and durability.

Industrial Machinery

Wear plates, gaskets, washers, and auxiliary components in fabricating hardware and preparing machinery.

Electronics Manufacturing

Test installations, dances, and mounting plates for electronic get together and testing operations.

OEM Service

We get it that each application has interesting prerequisites. Our experienced building group works closely with you to create customized solutions.

Design Consultation

Technical specialists offer assistance optimize fabric determination and determinations for your particular applications.

Custom Manufacturing

Tailored measurements, extraordinary shapes, and altered properties to meet your correct requirements.

Prototyping Services

Small-batch generation for testing and approval some time recently full-scale manufacturing.

Technical Support

Ongoing help with establishment, application direction, and execution optimization.

FAQ

Q: What makes G-10 different from other composite materials?

A: The combination of nonstop glass fiber fortification and epoxy tar gives predominant strength-to-weight proportion and fabulous electrical properties compared to other composite options.

Q: Can you provide custom colors?

A: Yes, we offer custom color options beyond our standard light green, yellow, and black. Contact us for specific color requirements and minimum quantities.

Q: What's the typical lead time for custom sizes?

A: Standard custom sizes regularly dispatch inside 2-3 weeks. Complex custom details may require extra time for fabricating setup.

Q: How do you ensure consistent quality?

A: Each group experiences comprehensive testing counting mechanical property confirmation, dimensional checking, and electrical execution assessment some time recently shipping.

Q: What packaging options are available?

A: We provide protective packaging with pallet support to prevent damage during shipping. Special packaging requirements can be accommodated.

Contact Us

Ready to discuss your G-10 Glass Fiber Plates requirements? Our technical team is here to help you select the right materials for your applications.

Get in touch today:

Email: info@jhd-material.com

Whether you require specialized determinations, custom citations, or application direction, we're committed to giving the master back you require for fruitful extend completion.

Send Inquiry

_1764832200426.jpg)

_1764832200434.jpg)