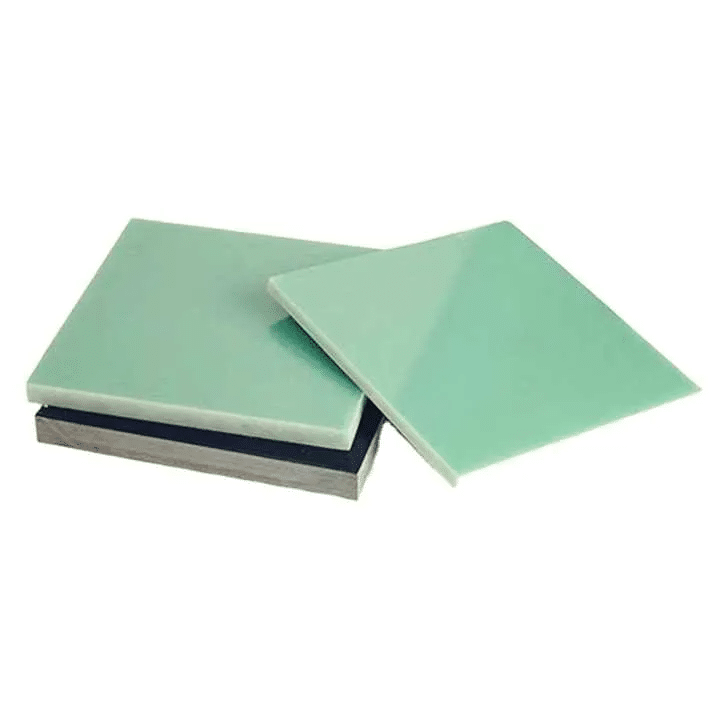

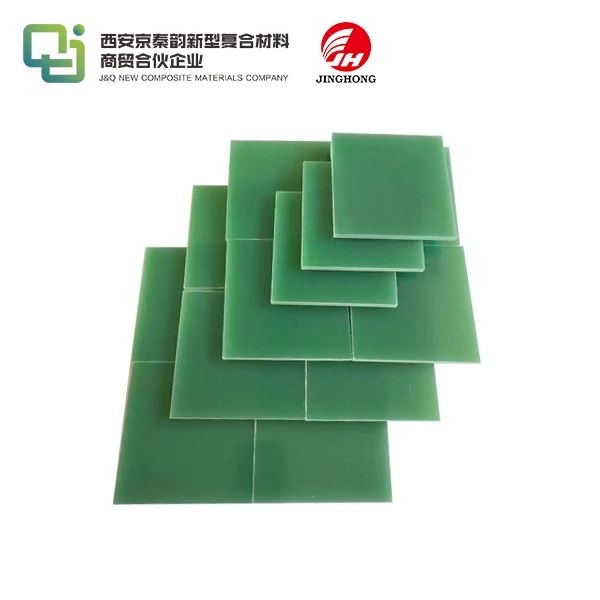

G10 Composite Material

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0

Nature Color: Light Green,Yellow,Black

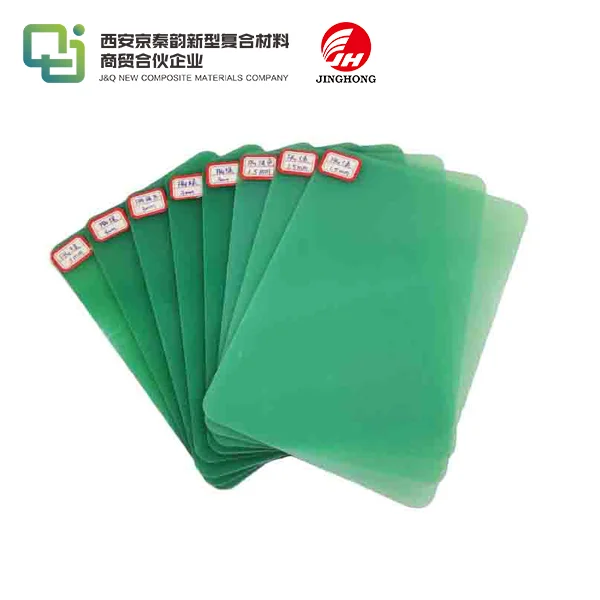

Thickness: 0.3mm --- 100mm

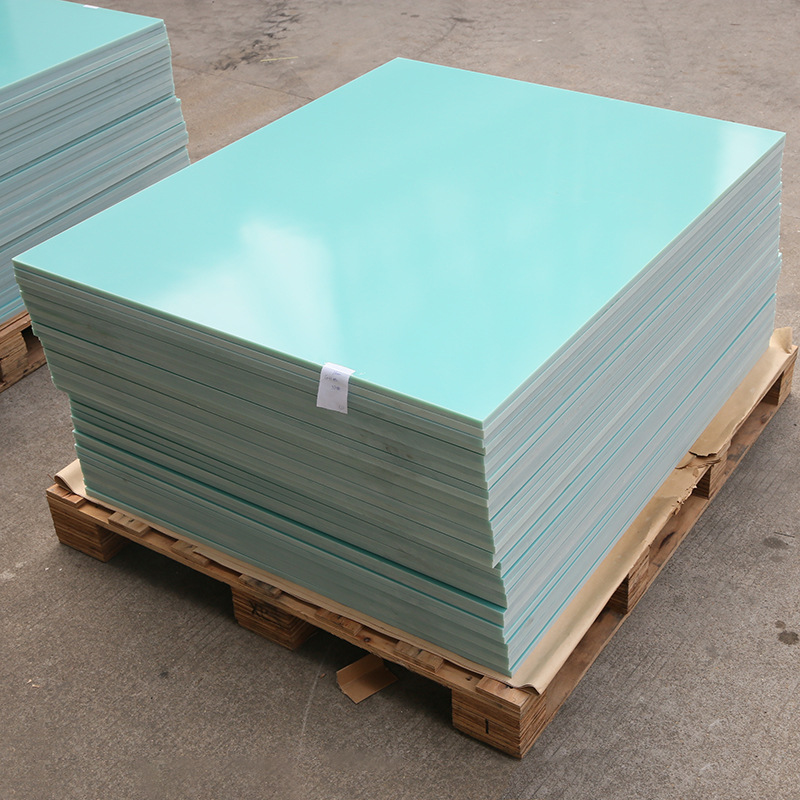

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

G10 Composite Material - High-Performance Electrical Insulation Solution

When you're looking for dependable electrical separator materials that provide remarkable execution over requesting applications, G10 Composite Material stands out as the industry-leading choice. Our JingHong brand G10 sheets combine progressed 7628 electronic cloth with premium epoxy gum, making a prevalent composite that meets the most elevated electrical and mechanical measures. This flame-retardant fabric offers extraordinary toughness and flexibility for your most basic projects.

Product Description from JingHong

Our G10 sheets speak to the culminate combination of progressed materials building and viable application needs. Each sheet combines high-quality 7628 electronic cloth with uncommonly defined epoxy tar, conveying reliable execution you can trust.

Brand: JingHong

Core Materials: 7628 Electronic Cloth + Premium Epoxy Resin

Flame Retardant Rating: UL94V0

Available Colors: Light Green, Yellow, Black

Thickness Range: 0.3mm to 100mm

Product Availability

We keep up broad stock to meet your venture timelines:

| Attribute | Details |

|---|---|

| Standard Sizes | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Dimensions Available | 1030mm × 2030mm, 1220mm × 2440mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Production Capacity | 30,000 tons annually |

| Minimum Order | 500KG |

| Packaging | Professional pallet protection for safe delivery |

Key Features

Your ventures request materials that perform reliably beneath weight. Our composite sheets deliver:

- Superior Electrical Cover: Amazing dielectric properties for electrical applications

- High Mechanical Quality: Remarkable toughness beneath mechanical stress

- Temperature Resistance: Performs dependably in both tall and low-temperature environments

- Chemical Resistance: Withstands presentation to different chemicals and solvents

- Dimensional Steadiness: Keeps up shape and properties over temperature variations

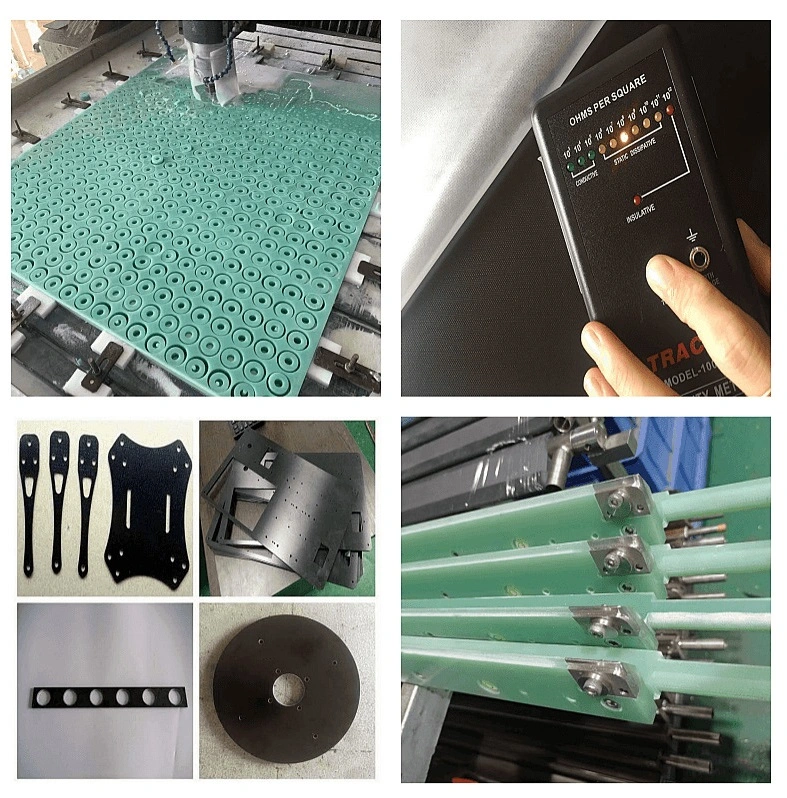

- Easy Machining: Cuts, drills, and shapes cleanly for exact applications

Standards Compliance

Our G10 Composite Material meets thorough worldwide benchmarks, guaranteeing you get reliable, solid execution for basic applications. The UL94V0 fire retardant rating gives extra security confirmation for electrical installations.

Technical Data for G10

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-1 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

Safety remains our beat need all through fabricating and application. Our quality control handle includes:

- Rigorous fabric testing at each generation stage

- Modulus of flexibility: 18-25 GPa for steady mechanical performance

- Low-temperature reasonableness for differing natural conditions

- Comprehensive electrical property verification

- Strict adherence to fire retardancy standards

Product Applications

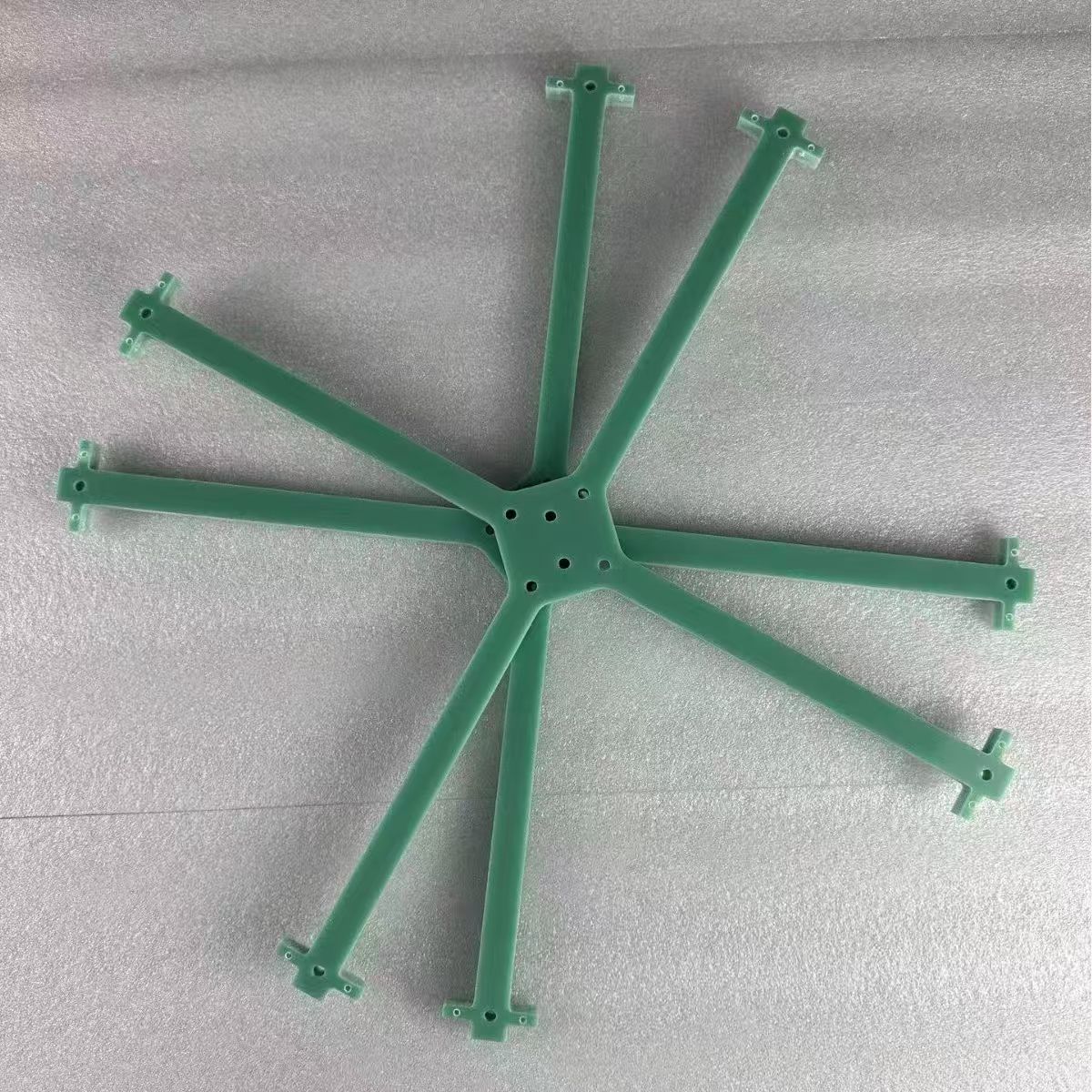

This flexible item serves different businesses and applications:

Electrical Industry:

- Switchgear components

- Electrical boards and enclosures

- Terminal sheets and insulators

Electronics Manufacturing:

- PCB substrates and supports

- Electronic component housings

- Test fixtures and jigs

Industrial Applications:

- Mechanical components requiring electrical insulation

- Structural supports in electrical environments

- Custom fabricated parts for specialized equipment

OEM Service

We get it that your applications regularly require particular measurements and setups. Our experienced group works closely with you to create custom arrangements that meet your correct details. From fabric determination to last wrapping up, we guarantee your custom sheets meet all execution requirements.

Environmental Responsibility

Our fabricating prepare prioritizes natural maintainability. The epoxy board contains no destructive substances and does not contaminate the environment amid generation or utilize. Furthermore, the fabric can be reused, decreasing asset squander and supporting your company's natural goals.

Frequently Asked Questions

Q: Is G10 suitable for low-temperature environments?

A: Yes, G10 performs superbly in low-temperature situations whereas keeping up its electrical and mechanical properties.

Q: What is the modulus of elasticity for G10?

A: Our G10 sheets include a modulus of flexibility extending from 18-25 GPa, giving great mechanical strength.

Q: How environmentally friendly is G10?

A: It is environmentally responsible, containing no harmful substances and offering recyclability to reduce waste.

Q: What flame retardant rating does your G10 achieve?

A: Our boards meet UL94V0 flame retardant standards, providing superior fire safety performance.

Q: Can you provide custom sizes beyond your standard offerings?

A: Absolutely! We specialize in custom dimensions to meet your specific application requirements.

Contact Us

Ready to discuss your G10 Composite Material requirements? Our technical team stands ready to help you select the perfect specifications for your application.

Email: info@jhd-material.com

Payment Terms: T/T

Shipping Options: Ocean, Land, and Air transportation available

Contact us nowadays to ask tests, specialized determinations, or custom cites. We're committed to giving the high-performance materials that control your victory.

Send Inquiry

_1764228361599.jpg)