G10 Glass Fiber Plate

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0

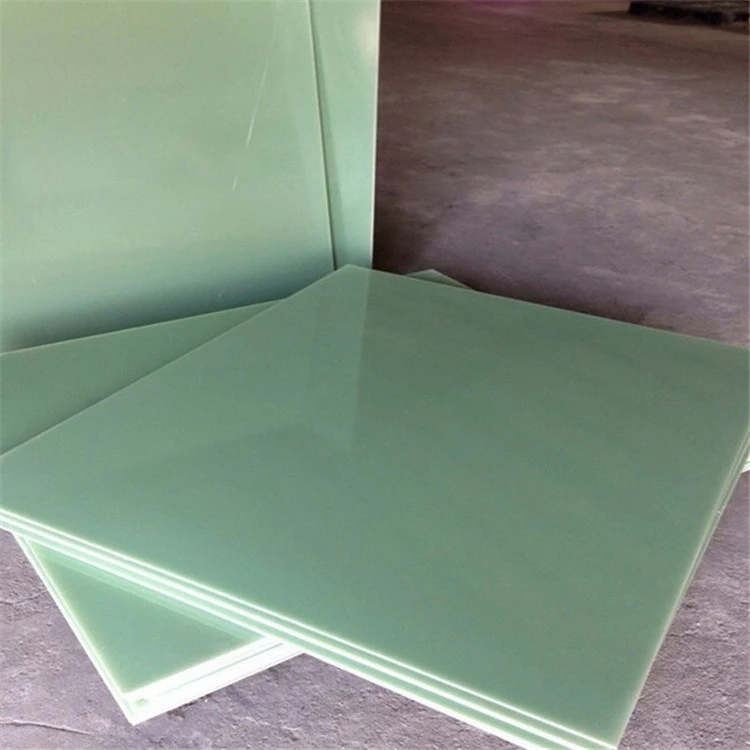

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

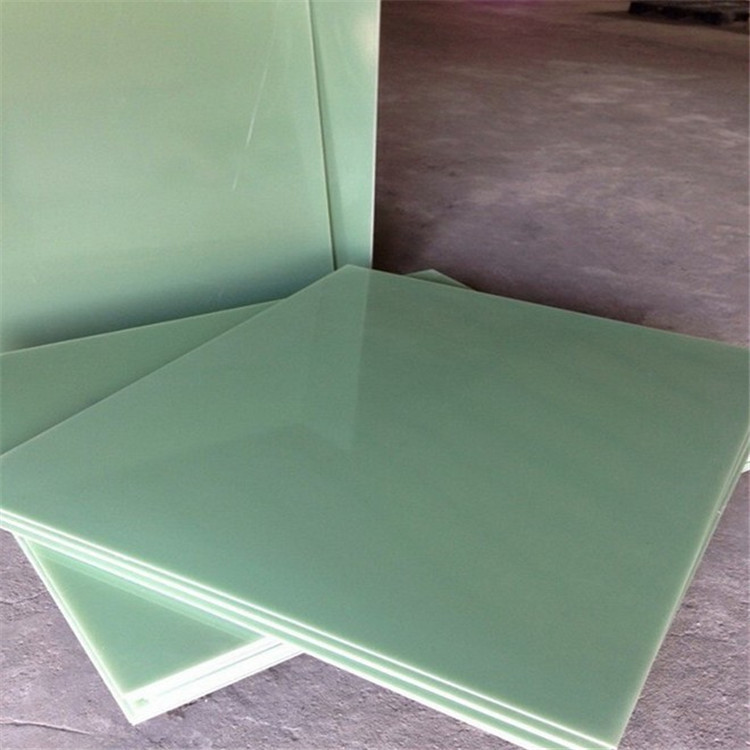

G10 Glass Fiber Plate - High-Performance Composite Material for Industrial Applications

The G10 Glass Fiber Plate from JingHong conveys remarkable execution for requesting mechanical applications. This premium composite fabric combines 7628 electronic cloth with high-quality epoxy gum to make a solid, flame-retardant arrangement. Whether you require electrical cover, mechanical components, or specialized mechanical parts, our product offers the unwavering quality and execution you request for your basic applications.

Product Description from Supplier

Our items are made utilizing progressed composite innovation. We combine premium 7628 electronic cloth with predominant epoxy gum frameworks. This makes a fabric that conveys extraordinary electrical separator properties and mechanical strength.

The fabricating handle guarantees reliable quality over all thickness ranges. Each plate experiences thorough quality control testing. This ensures you get materials that meet the most noteworthy industry standards.

Product Availability

Available Specifications:

| Attribute | Details |

|---|---|

| Thickness Range | 0.3mm to 100mm |

| Standard Sizes | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Sizes | 1030mm × 2030mm, 1220mm × 2440mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Colors | Light Green, Yellow, Black |

| Minimum Order | 500KG |

| Annual Capacity | 30,000 tons |

Key Features

Superior Electrical Properties

The glass fiber fortified development gives amazing dielectric quality. You get solid electrical cover indeed beneath tall voltage conditions.

Outstanding Mechanical Strength

High malleable quality and flexural properties make these plates appropriate for basic applications. The fabric keeps up astuteness beneath mechanical stress.

Excellent Machinability

You can effectively prepare these plates utilizing routine machining strategies. Cutting, boring, and processing operations create clean, exact results.

Temperature Stability

Maintains dimensional soundness over wide temperature ranges. Culminate for applications requiring reliable execution in changing warm conditions.

Standards

Our G10 Glass Fiber Plate comply with international quality standards:

- UL94V0 fire retardant classification

- NEMA Review G10 specifications

- IEC electrical separator standards

- RoHS natural compliance

Technical Features: Product Safety Control

Flame Retardancy

UL94V0 rating guarantees prevalent fire resistance. The fabric self-extinguishes rapidly when fire source is removed.

Low Thermal Conductivity

Thermal conductivity ranges between 0.3-0.4 W/m·K. This gives successful warm cover for temperature-sensitive applications.

High Fracture Toughness

Superior vitality retention capabilities ensure against affect and vibration harm. The fabric stands up to break proliferation effectively.

Chemical Resistance

Excellent resistance to oils, solvents, and numerous mechanical chemicals. This amplifies benefit life in cruel working environments.

Technical Data for G10

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-1 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Product Applications

Electrical Industry

- Switchgear insulation panels

- Terminal boards and bus supports

- Transformer components

- Circuit breaker parts

Mechanical Engineering

- Precision jigs and fixtures

- Wear plates and guides

- Structural components

- Machine tool parts

Electronics Manufacturing

- PCB drilling fixtures

- Test equipment components

- Electronic enclosures

- Insulation barriers

OEM Service

We get it that each application has one of a kind prerequisites. Our experienced building group works closely with you to create customized solutions.

Custom Manufacturing Options:

- Precision CNC machining services

- Custom size cutting

- Special surface treatments

- Application-specific modifications

Our adaptable generation capabilities oblige both model amounts and large-scale fabricating runs.

FAQ

Q: What makes G10 different from other composite materials?

A: G10 offers prevalent electrical separator combined with great mechanical properties. The epoxy gum framework gives way better chemical resistance compared to phenolic-based materials.

Q: Can you machine complex shapes from these plates?

A: Yes, our products composite machines perfectly. It produces smooth surfaces and keeps up tight resiliences amid CNC operations.

Q: What thickness tolerances can you maintain?

A: We keep up strict thickness resistances over our whole run. Standard resiliences change by thickness, with more tightly details accessible upon request.

Q: How do you ensure consistent quality?

A:Each bunch experiences comprehensive testing counting electrical, mechanical, and warm property confirmation. We keep up point by point quality records for full traceability.

Q: What packaging options are available?

A: Standard defensive bundling incorporates bed assurance for secure shipping. We can customize bundling based on your particular taking care of requirements.

Contact Us

Ready to discuss your G10 Glass Fiber Plate requirements? Our technical team stands ready to help you select the optimal specifications for your application.

Get in touch today:

Email: info@jhd-material.com

We give specialized bolster, custom citations, and application direction. Whether you require standard sizes or custom arrangements, we convey the quality and benefit you anticipate from a trusted composite fabric provider.

Send Inquiry