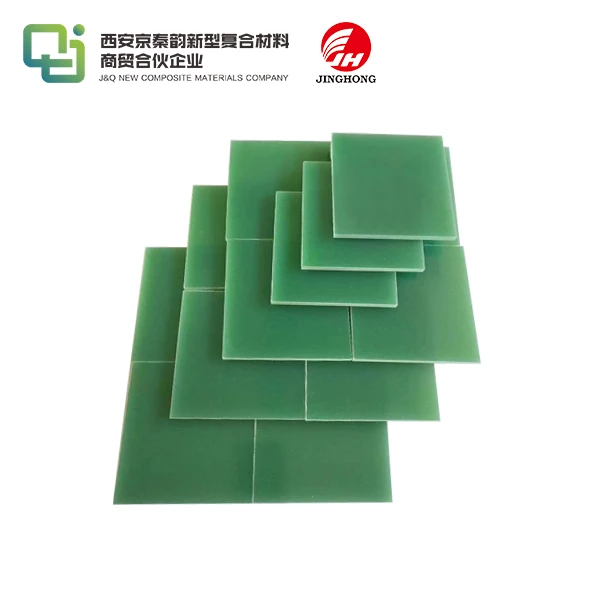

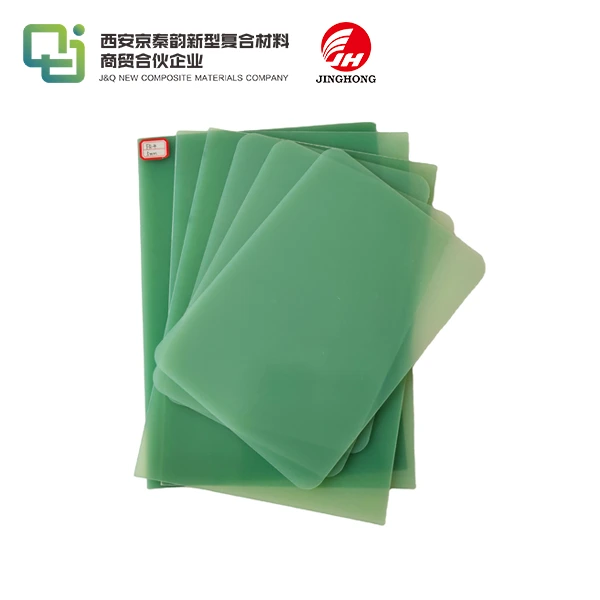

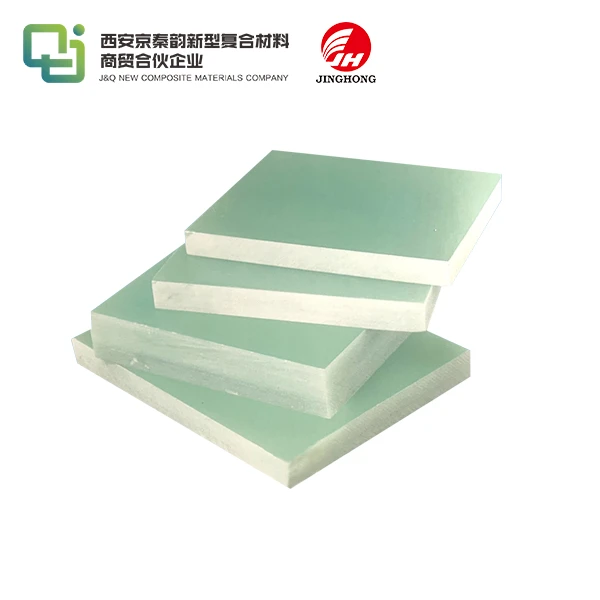

G10 Fr4 Plate

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0,UL94V1

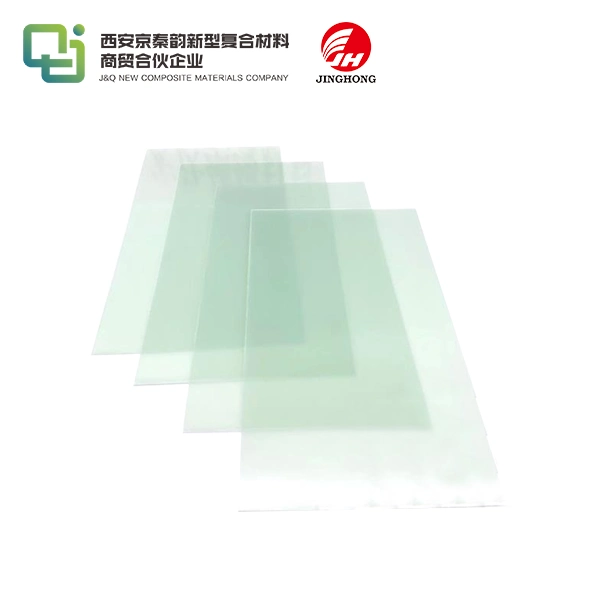

Nature Color: Light Green,Yellow,Black

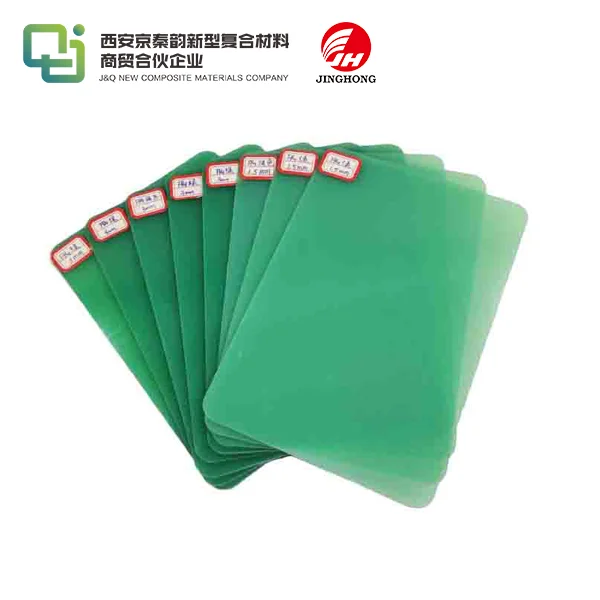

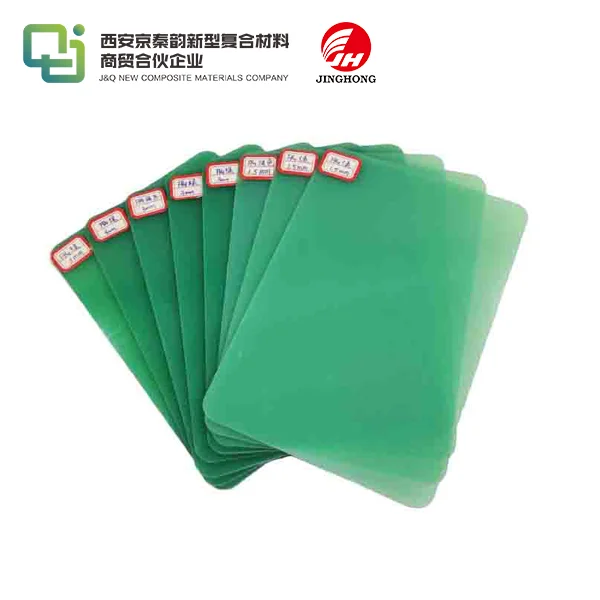

Thickness: 0.3mm --- 100mm

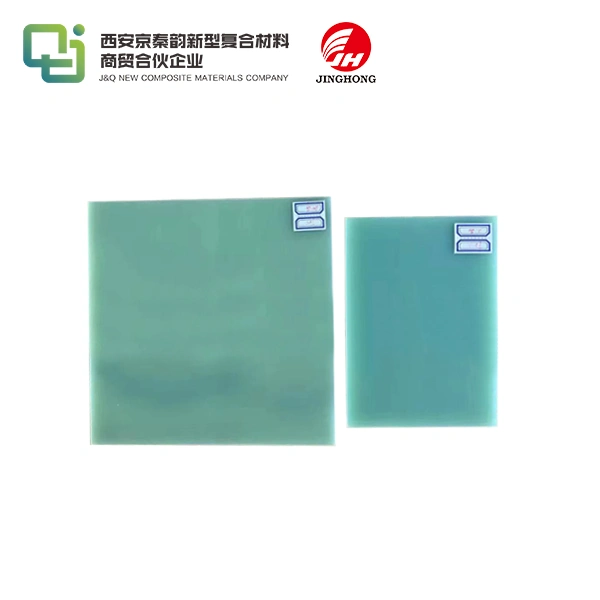

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

G10 Fr4 Plate - High-Performance Fiberglass Epoxy Laminate

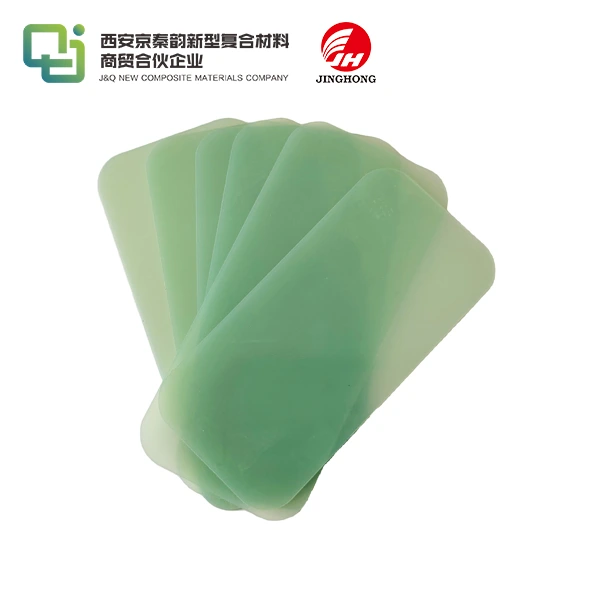

Our G10 Fr4 Plate combines extraordinary mechanical quality with extraordinary electrical properties. This high-grade fiberglass epoxy cover offers predominant execution for requesting applications. Made with 7628 electronic cloth and premium epoxy gum, each plate conveys reliable quality you can believe. Whether you require fire retardant properties or amazing dimensional steadiness, this flexible fabric meets your prerequisites. Accessible in different thicknesses and custom sizes, our plates serve businesses from hardware to aviation with demonstrated reliability.

Product Description from Supplier

JingHong brand fiberglass epoxy plates speak to a long time of fabricating ability. Our generation office makes these composite materials utilizing progressed compression molding procedures. Each sheet experiences thorough quality control to guarantee uniform properties all through. The combination of woven glass texture and thermosetting epoxy tar makes a fabric that stands up to dampness, chemicals, and temperature extremes.

Product Availability

Standard Specifications:

| Specification | Details |

|---|---|

| Thickness Range | 0.3mm to 100mm |

| Standard Sizes | 1020mm × 1220mm,1220mm × 2440mm,1020mm × 2020mm |

| Custom Dimensions | 1030mm × 2030mm,1030mm × 1030mm,1030mm × 2070mm |

| Colors Available | Light Green, Yellow, Black |

| Annual Production Capacity | 30,000 tons |

| Minimum Order Quantity | 500KG |

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Key Features

Your ventures advantage from these exceptional characteristics:

- Excellent Electrical Insulation: Dielectric strength of 15-20 kV/mm

- Wide Temperature Range: Operates from -50°C to +130°C

- Superior Mechanical Strength: High impact resistance and dimensional stability

- Chemical Resistance: Withstands oils, solvents, and moisture

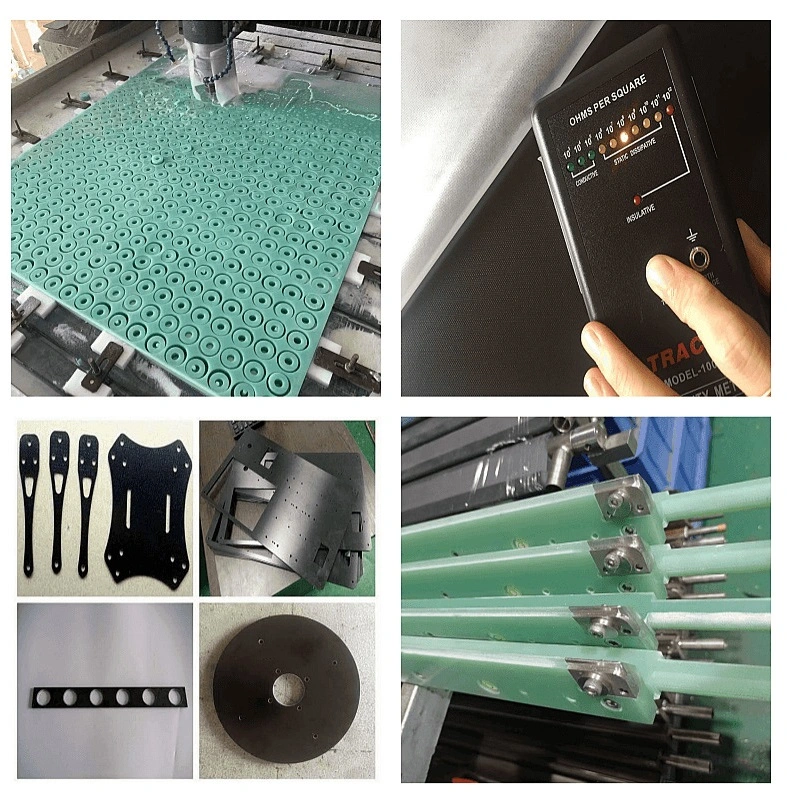

- Easy Machining: Cuts, drills, and shapes without delamination

- Consistent Quality: Uniform thickness and surface finish

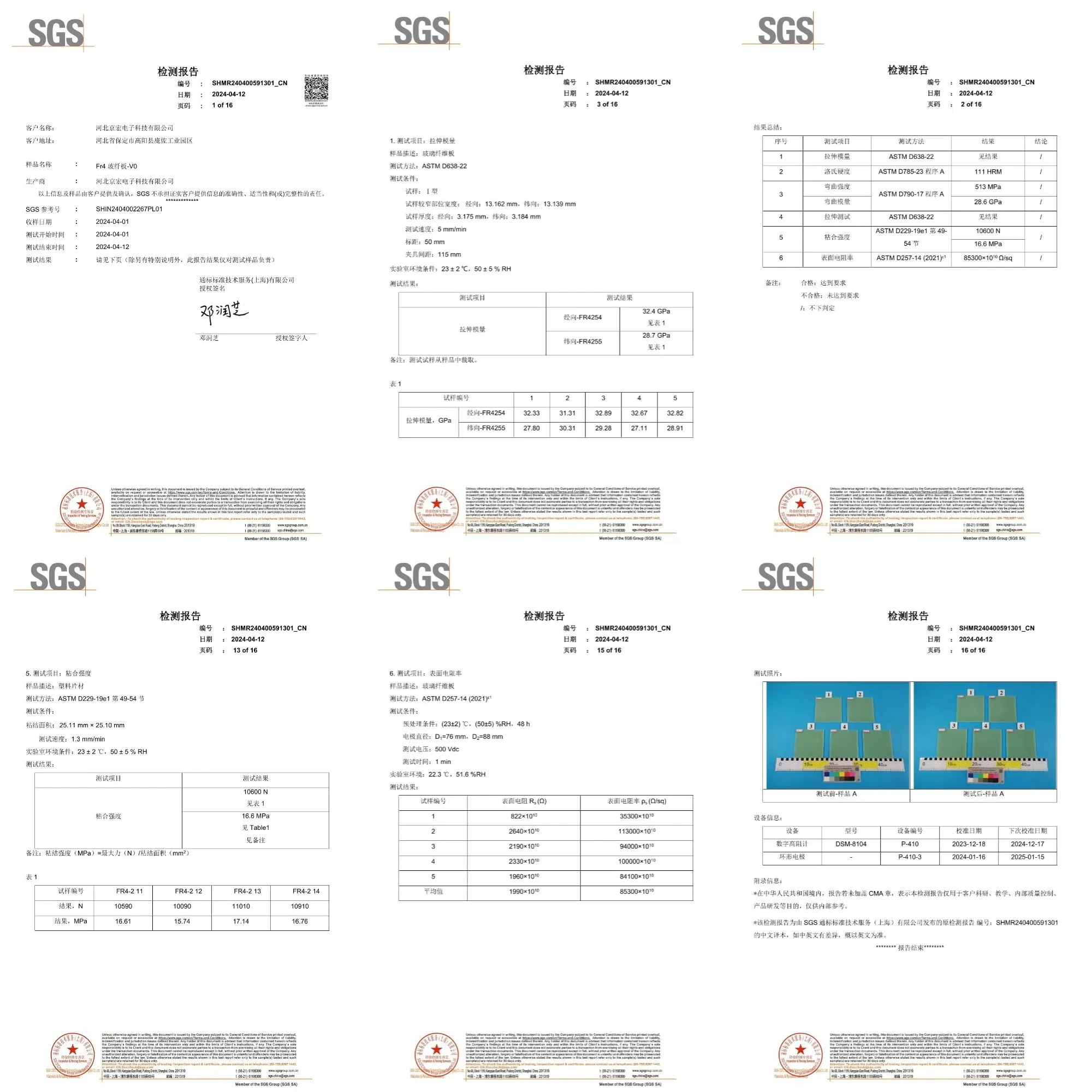

Standards

Our fabricating forms comply with worldwide quality standards:

- UL94 Fire Rating: V0 and V1 classifications available

- IEC Benchmarks: Meets electrical separator requirements

- ASTM Testing: Mechanical and warm properties verified

- ISO Quality Frameworks: Fabricating beneath certified quality management

Technical Features: Product Safety Control

Every G10 Fr4 Plate experiences comprehensive testing some time recently shipment. Our quality control research facility screens dielectric quality, flexural properties, and fire resistance. Temperature cycling tests guarantee solid execution over the indicated extend. We keep up nitty gritty bunch records for total traceability.

Safety features include:

- Flame retardant added substances for fire protection

- Non-toxic materials reasonable for encased applications

- Smooth surfaces that stand up to defilement buildup

- Lead-free composition for natural compliance

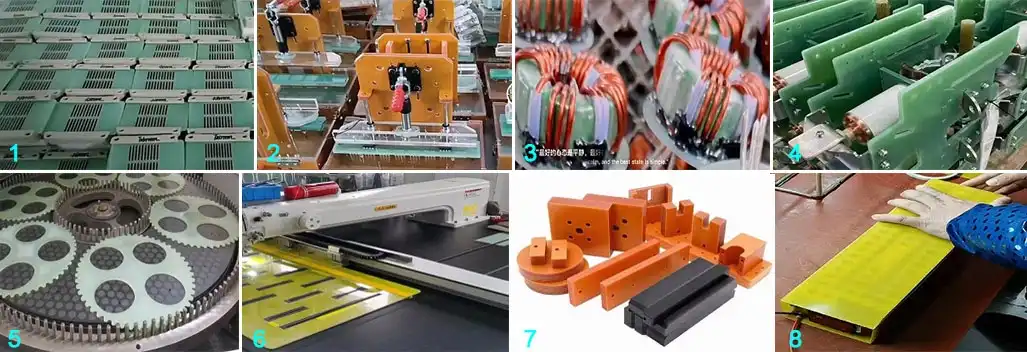

Product Application

These flexible plates serve various industries:

Electrical Applications:

- Circuit board substrates and supports

- Transformer insulation barriers

- Switchgear components

- Motor slot wedges and spacers

Mechanical Uses:

- Bearing plates and washers

- Structural underpins in destructive environments

- Jigs and installations for manufacturing

- Prototype components requiring precision

Specialized Applications:

- Aerospace interior panels

- Marine electrical enclosures

- Chemical processing equipment

- Cryogenic insulation systems

OEM Service

We get it that your applications may require particular measurements or properties. Our building group works closely with you to create custom arrangements. Whether you require special thickness combinations, uncommon surface medicines, or altered electrical properties, we can adjust our fabricating process.

Custom services include:

- Precision cutting to your specifications

- Surface texturing or coating application

- Modified resin formulations for special requirements

- Private labeling for distributor partnerships

Certification

Quality certifications illustrate our commitment to greatness. Whereas we keep up thorough testing conventions, we prescribe reaching our specialized group for particular certification documentation pertinent to your application requirements.

FAQ

Q: What's the difference between G10 and FR4 variants?

A: FR4 typically offers V0 flame retardancy, while G10 provides V1 rating with excellent low-temperature performance.

Q: Can these plates be machined easily?

A: Yes, standard woodworking and metalworking tools handle these materials well. Use sharp tools and moderate speeds for best results.

Q: How do I select the right thickness?

A: Consider your electrical requirements, mechanical loads, and space constraints. Our technical team can recommend optimal thickness for your application.

Q: What storage conditions are recommended?

A: Store in dry conditions away from direct sunlight. Normal warehouse temperatures are suitable for long-term storage.

Q: Are custom colors available?

A: Yes, we can produce custom colors for larger quantities. Contact us to discuss your specific color requirements.

Contact Us

Ready to discuss your G10 Fr4 Plate requirements? Our technical team provides expert guidance for material selection and application support.

Get in touch today:

- Email: info@jhd-material.com

- We respond to all inquiries within 24 hours

- Technical consultation available

- Sample requests welcome

Let us offer assistance you discover the culminate arrangement for your following venture. Our experienced group gets it the interesting challenges you confront and can prescribe the perfect fabric determinations for your victory.

Send Inquiry

_1732777843529.webp)