Fr4 Epoxy Glass Sheets

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0,UL94V1

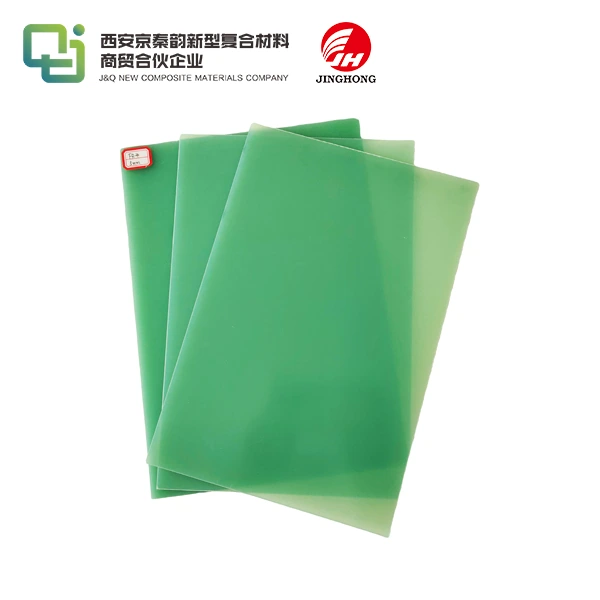

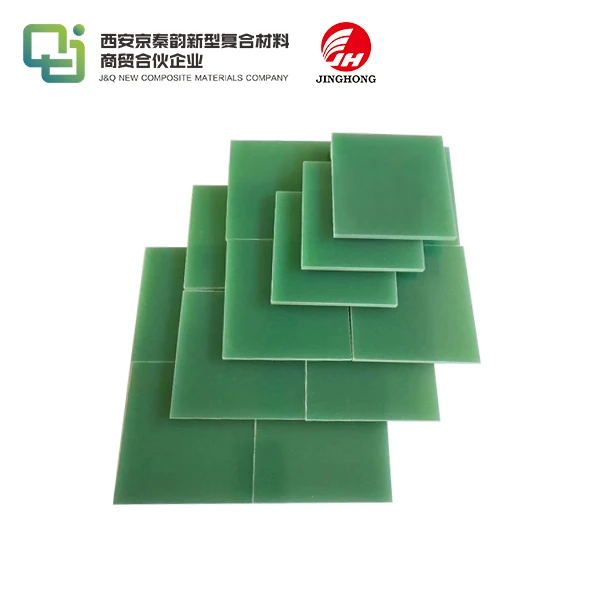

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Fr4 Epoxy Glass Sheets - Premium Quality Electronic Insulation Material

Our Fr4 Epoxy Glass Sheets from JingHong brand convey uncommon execution and solidness. These high-grade composite materials combine 7628 electronic cloth with epoxy gum to make prevalent electrical cover arrangements. Whether you require standard sizes or custom measurements, our items meet the requesting prerequisites of cutting edge hardware fabricating. With exceptional dimensional steadiness and amazing electrical properties, these sheets give the unwavering quality your applications demand.

Product Descriptions from the Supplier

Our epoxy glass sheets include premium 7628 electronic cloth support with high-quality epoxy gum network. This combination makes a strong composite fabric that exceeds expectations in electrical separator applications. The fabricating prepare guarantees steady quality and execution over all item batches.

Description

These composite cover sheets offer remarkable warm soundness and mechanical quality. The epoxy gum lattice gives great attachment to the glass fiber fortification, making a uniform fabric with unsurprising properties. Your ventures advantage from the prevalent electrical characteristics and dimensional soundness that make these sheets perfect for basic applications.

Product Availability

Available Specifications:

| Attribute | Details |

|---|---|

| Thickness Range | 0.3mm to 100mm |

| Standard Sizes | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Dimensions | 1030mm × 2030mm, 1220mm × 2440mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Color Options | Light Green, Yellow, Black |

| Minimum Order | 500KG |

| Annual Capacity | 30,000 tons |

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Key Features

Superior Electrical Performance

- High dielectric quality for solid insulation

- Excellent surface spillage resistance

- Outstanding bend resistance properties

- Volume resistivity surpassing 10¹² Ω·cm

- Stable dielectric consistent over temperature ranges

Exceptional Mechanical Properties

- Low curing shrinkage rate (<0.2%)

- Outstanding dimensional stability

- Excellent machinability for custom shapes

- Superior drilling and cutting performance

- Minimal warping in extended dimensions

Standards

Our Fr4 Epoxy Glass Sheets comply with UL94 flame retardant standards:

- UL94V0: Highest flame retardant grade

- UL94V1: Standard flame retardant grade

These certifications guarantee your applications meet security prerequisites and industry standards.

Technical Features: Product Safety Control

Quality Assurance Process:

- Rigorous fabric testing at each generation stage

- Consistent thickness resilience control

- Surface quality assessment protocols

- Electrical property confirmation testing

- Dimensional exactness confirmation

Safety Features:

- Self-extinguishing fire retardant properties

- Low smoke outflow characteristics

- Stable execution beneath warm cycling

- Resistance to chemical degradation

Product Application

Electronics Industry:

- Printed circuit board substrates

- Transformer cover components

- Motor space wedges and barriers

- Electrical board insulation

- Switch equip applications

Industrial Applications:

- High-temperature separator components

- Chemical handling gear parts

- Mechanical back structures

- Custom machined cover parts

The moo warm extension coefficient of our materials guarantees negligible distorting in extra-long sheets, ensuring accuracy in fabricating applications.

OEM Service

We give comprehensive customization administrations to meet your particular requirements:

Custom Manufacturing Options:

- Tailored dimensions beyond standard sizes

- Specialized thickness requirements

- Custom color specifications

- Unique packaging solutions

- Modified material properties

Technical Support:

- Application engineering assistance

- Material selection guidance

- Processing recommendations

- Quality specification development

Certification

Our fabricating office keeps up high-quality measures with efficient quality control forms. All items experience comprehensive testing to guarantee steady execution and reliability.

FAQ

Q: What makes these sheets suitable for electronic applications?

A: The combination of tall dielectric quality, fabulous dimensional soundness, and prevalent electrical separator properties makes them perfect for electronic components.

Q: Can you provide custom sizes for specific projects?

A: Yes, we offer custom measurements and can make sheets concurring to your correct details with our adaptable generation capabilities.

Q: What is the typical lead time for orders?

A: Lead times shift based on arrange measure and determinations. Contact us for particular conveyance plans based on your requirements.

Q: How do you ensure consistent quality across batches?

A: We keep up strict quality control conventions all through generation, counting fabric testing, dimensional confirmation, and electrical property confirmation.

Q: What packaging options are available?

A: We give customary bundling with bed assurance for secure transportation. Custom bundling arrangements are accessible upon request.

Contact Us

Ready to discuss your Fr4 Epoxy Glass Sheets requirements? Our technical team is here to help you select the right specifications for your applications.

Get in touch today:

- Email: info@jhd-material.com

- Payment Terms: T/T accepted

- Transportation: Ocean, Land, and Air freight options available

Whether you require standard measurements or custom arrangements, we're committed to giving high-quality materials that meet your correct determinations. Contact us to learn more almost our items and administrations.

Send Inquiry

拷贝_1764314565411.jpg)

_1764314565728.jpg)

_1764314565407.jpg)

_1764314565376.jpg)

拷贝.webp)