Fr4 Epoxy Material Properties

Basic Information:

Brand:JingHong

Materials: 7628 electronic cloth + Epoxy Resin

Grade: UL94V1,UL94V0,NEMA

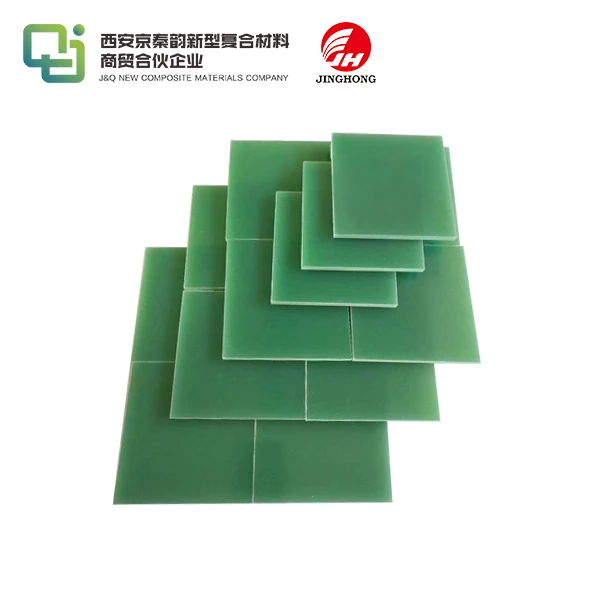

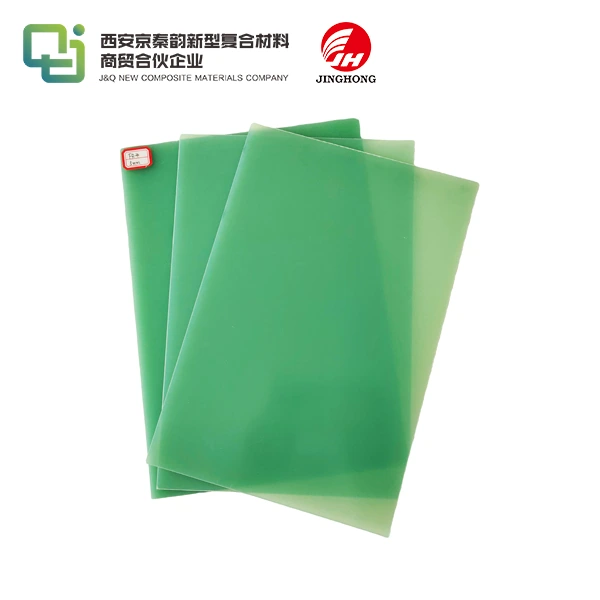

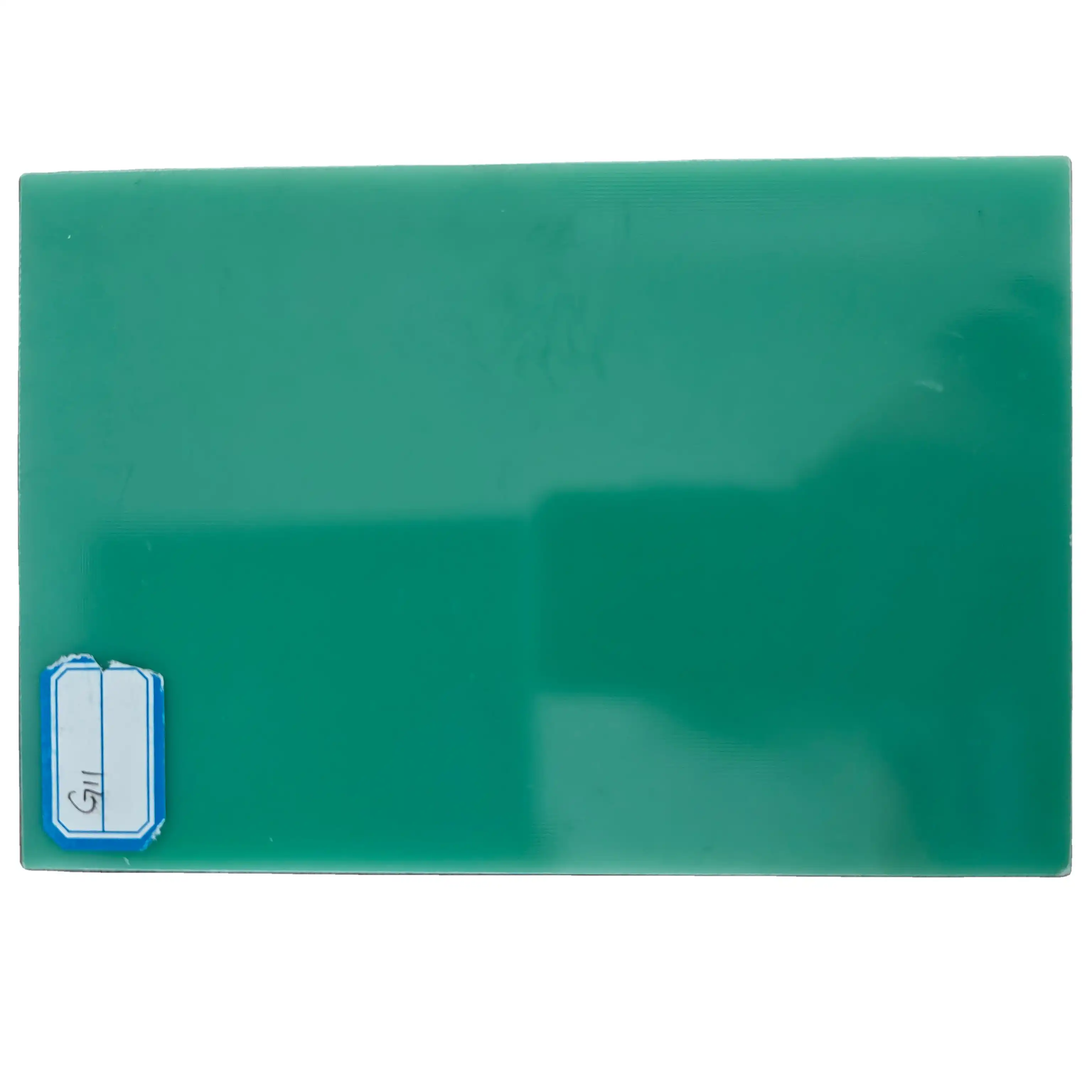

Nature Color: Light Green

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm,1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Fr4 Epoxy Material Properties: Premium Electronic Insulation Solutions

When you're searching for reliable electronic insulation materials, understanding Fr4 Epoxy Material Properties gets to be pivotal for your extend victory. Our JingHong brand FR4 materials combine 7628 electronic cloth with high-quality epoxy gum, conveying uncommon execution for electronic applications. These materials offer predominant electrical separator, mechanical quality, and warm steadiness that your industry requests. Whether you require standard measurements or custom determinations, our product ensure reliable quality and unwavering quality for your fabricating processes.

Product Descriptions from the Supplier

Our FR4 epoxy sheets speak to the idealize combination of progressed materials innovation and fabricating fabulousness. Each board comprises of woven fiberglass cloth (7628 electronic cloth) impregnated with epoxy gum, making a composite fabric that conveys exceptional execution over numerous applications.

The signature light green color makes distinguishing proof simple in your generation environment. You can select from thickness alternatives extending from 0.3mm to 100mm, pleasing everything from fragile electronic components to heavy-duty mechanical applications.

Product Availability

We keep up reliable stock levels with a generation capacity of 30,000 tons every year.

| Specification | Details |

|---|---|

| Standard Sizes Available | 1020mm × 1220mm |

| 1220mm × 2440mm | |

| 1020mm × 2020mm | |

| Custom Dimensions Available | 1030mm × 2030mm |

| 1030mm × 1030mm | |

| 1030mm × 2070mm |

Minimum arrange amount begins at 500KG, guaranteeing cost-effective obtainment for your projects.

Key Features

Our FR4 materials provide remarkable esteem through these standout characteristics:

Superior Electrical Separator: Tall dielectric quality anticipates electrical breakdown in requesting applications.

Excellent Mechanical Properties: Pliable quality of 282MPa gives strong auxiliary integrity.

Optimal Thickness: At 2.01g/cm³, the fabric offers an perfect strength-to-weight ratio.

Temperature Solidness: Keeps up execution over wide temperature ranges.

Easy Machinability: Exact cutting, penetrating, and forming capabilities for complex geometries.

Standards

Our items comply with globally recognized standards:

- NEMA Review: Meets National Electrical Producers Affiliation specifications

- UL94V0: Most elevated fire retardancy rating for basic security applications

- UL94V1: Standard fire retardancy for common electronic use

These certifications guarantee your ventures meet rigid security and execution requirements.

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

Safety remains our beat need all through the fabricating handle. Our quality control frameworks include:

Raw Fabric Assessment: Each group of electronic cloth and epoxy tar experiences thorough testing some time recently production.

Process Observing: Nonstop temperature, weight, and curing time controls guarantee reliable Fr4 Epoxy Material Properties.

Final Testing: Each wrapped up board gets comprehensive electrical and mechanical property verification.

Traceability Frameworks: Total documentation tracks materials from source to conveyance, empowering fast reaction if issues arise.

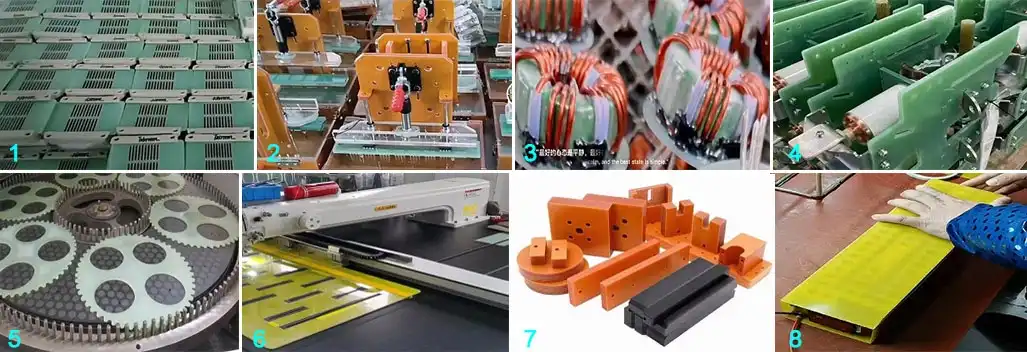

Product Application

Our FR4 materials serve different businesses and applications:

Electronics Fabricating: PCB substrates, component mounting bases, and electrical housings.

Industrial Gear: Engine lodgings, transformer components, and control board assemblies.

Aerospace: Lightweight basic components requiring fabulous strength-to-weight ratios.

Automotive: Electrical framework components requesting tall temperature resistance.

Telecommunications: Hardware lodgings and component underpins in communication systems.

OEM Service

We get it that your applications may require particular adjustments. Our OEM capabilities include:

Custom Measurements: Exact cutting to your correct details decreases squander and handling time.

Surface Medications: Uncommon wraps up upgrade grip, conductivity, or appearance as needed.

Packaging Arrangements: Defensive bundling custom fitted to your taking care of and capacity requirements.

Technical Back: Our building group collaborates with you to optimize fabric choice and application methods.

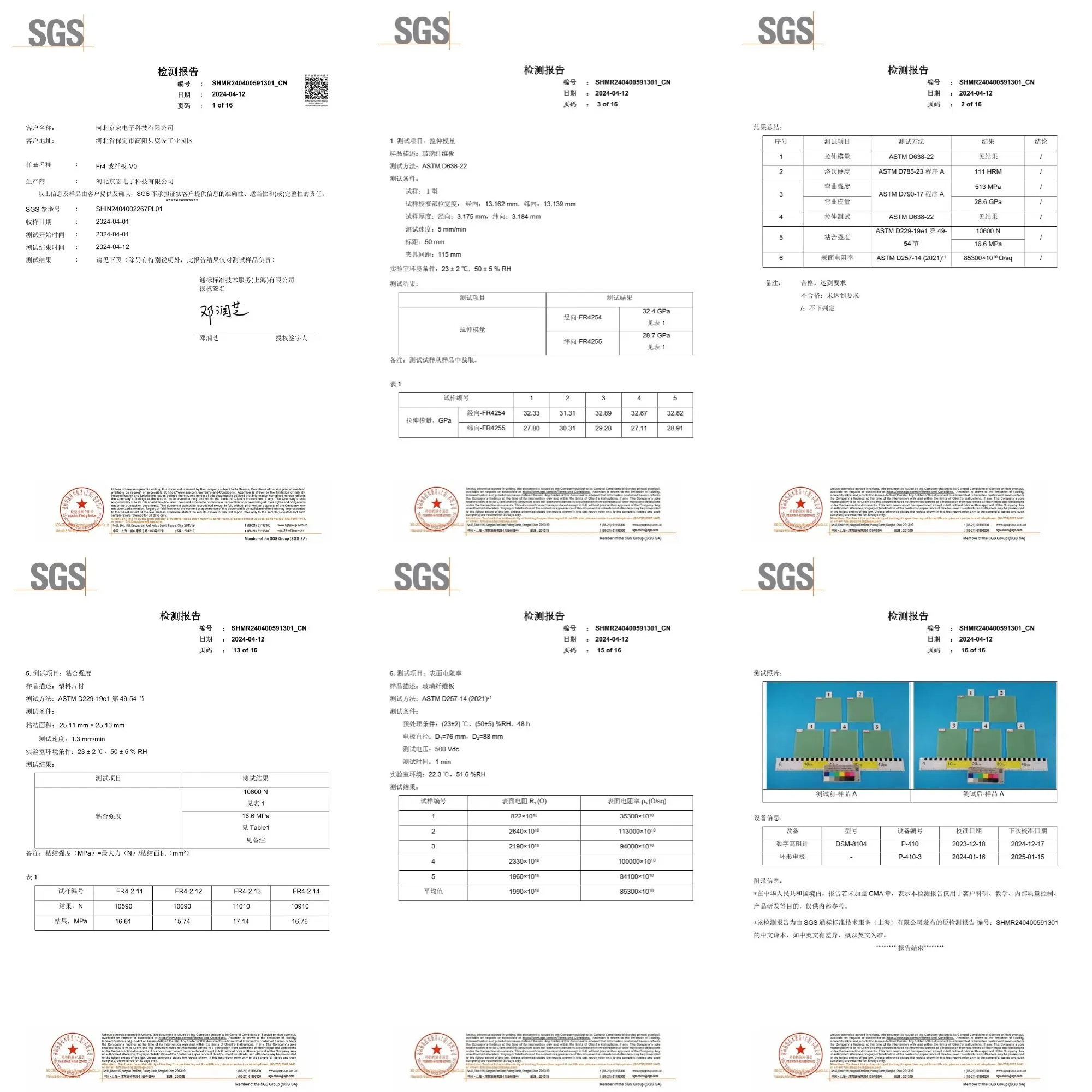

Certification

FAQ

Q: Is your insulation board flame retardant?

A: Yes, our FR4 flame retardancy ratings include both UL94V0 and UL94V1 grades, providing options for different safety requirements.

Q: What is the density of FR4 epoxy board?

A: Our FR4 materials have a density of 2.01g/cm³, offering excellent strength-to-weight performance.

Q: What is the tensile strength of FR4 insulation board?

A: The tensile strength reaches 282MPa, providing robust mechanical properties for demanding applications.

Q: What transportation options are available?

A: We offer ocean, land, and air transportation to meet your delivery timeline requirements.

Q: What payment terms do you accept?

A: We accept T/T (Telegraphic Transfer) for secure and efficient transactions.

Contact Us

Ready to explore how our Fr4 Epoxy Material Properties can enhance your next project? Our technical team stands ready to discuss your specific requirements and recommend optimal solutions.

Contact us today at info@jhd-material.com for point by point determinations, estimating data, or specialized discussions. We see forward to collaborating with you on your electronic materials needs.

Send Inquiry

拷贝.webp)