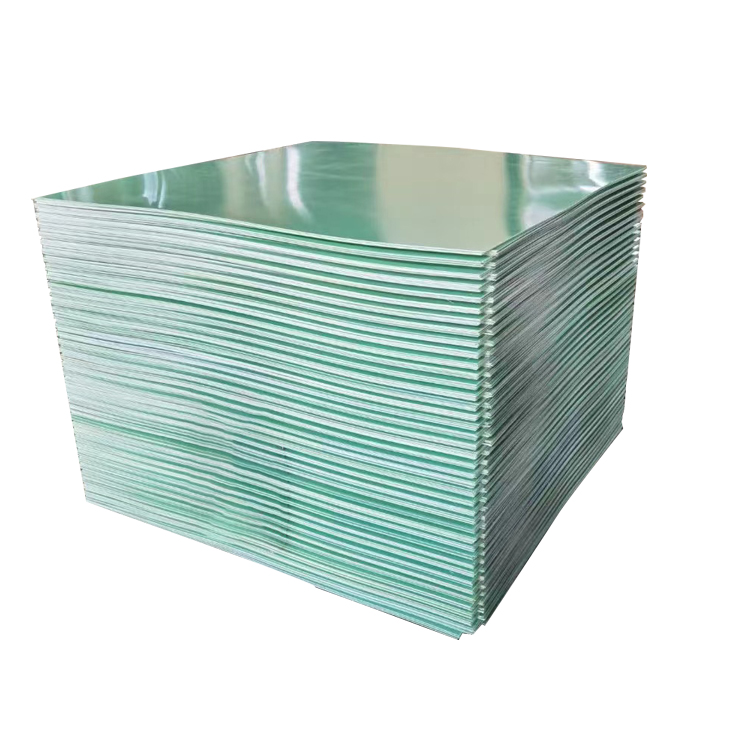

Fr-4 Glass Epoxy Laminate

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0,UL94V1

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Fr-4 Glass Epoxy Laminate - High Performance Electronic Material

When you require dependable electronic separator materials, our Fr-4 Glass Epoxy Laminate conveys uncommon execution for your applications. This premium composite fabric combines 7628 electronic cloth with progressed epoxy gum innovation. You get predominant mechanical quality, warm solidness, and electrical separator properties that meet requesting industry necessities. Our product features fire retardant grades UL94V0 and UL94V1 for upgraded safety.

Product Description from JingHong

Our JingHong brand materials speak to cutting-edge composite innovation. Each sheet experiences accuracy fabricating forms to guarantee reliable quality. You get materials that meet universal benchmarks for electronic applications.

The fabricating prepare combines high-quality 7628 electronic cloth with premium epoxy gum frameworks. This makes a cover with great dimensional steadiness and mechanical properties.

Product Availability

| Attribute | Details |

|---|---|

| Available Colors | Light Green, Yellow, Black |

| Thickness Range | 0.3mm to 100mm |

| Standard Dimensions | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Sizing Options | 1030mm × 2030mm, 1220mm × 2440mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Minimum Order Quantity | 500KG |

| Annual Production Capacity | 30,000 tons |

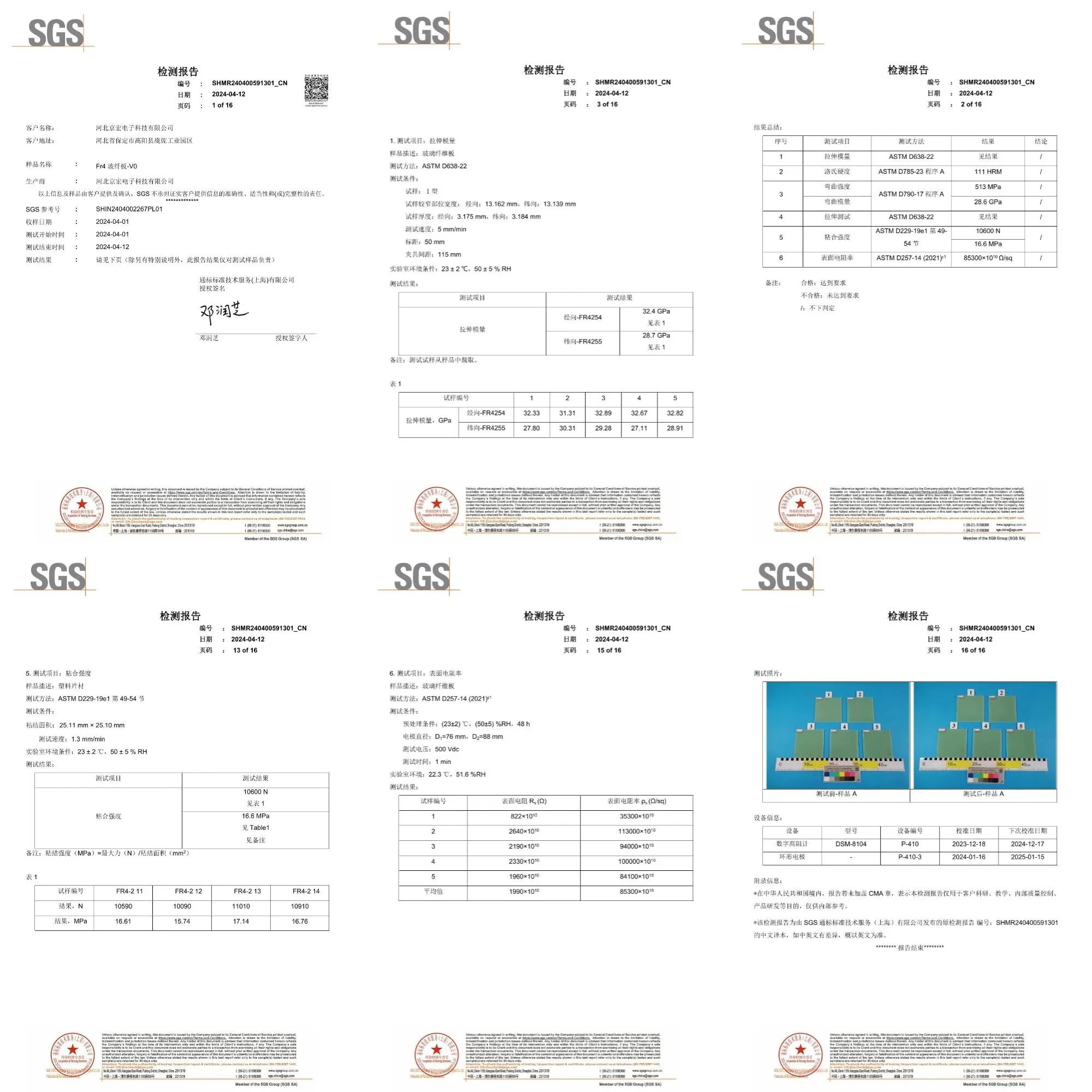

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Key Features

You advantage from these extraordinary fabric characteristics:

- High Mechanical Quality: Young's modulus ranges from 20-30 GPa, coming to up to 40 GPa

- Superior Affect Resistance: Parallel-layer affect quality ≥230 kJ/m²

- Excellent Warm Execution: High-temperature resistance for requesting applications

- Lightweight Plan: Ideal strength-to-weight ratio

- Flame Retardant Properties: UL94V0 and UL94V1 appraisals for security compliance

Standards Compliance

Our materials meet thorough industry benchmarks for electronic applications. The UL94 fire retardant classifications guarantee your ventures comply with security directions. These certifications illustrate our commitment to quality and reliability.

Technical Features: Product Safety Control

Quality Assurance Measures:

- Comprehensive fabric testing protocols

- Dimensional precision verification

- Electrical property validation

- Thermal execution assessment

- Surface quality inspection

Each clump experiences intensive testing to guarantee reliable execution. You get materials that meet indicated resiliences and execution criteria.

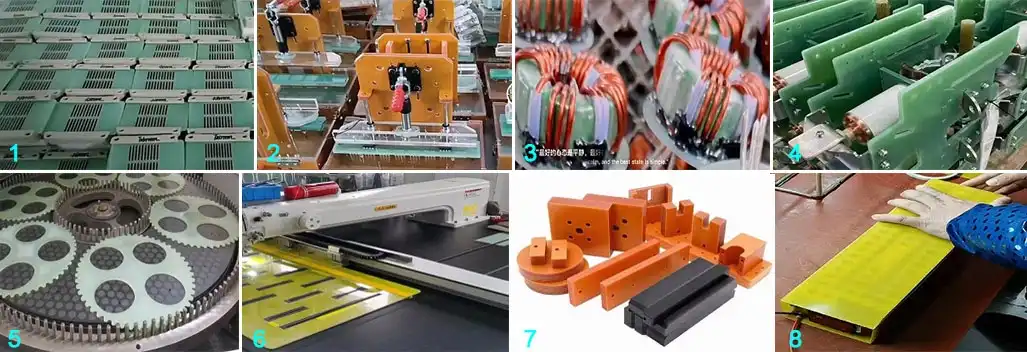

Product Applications

This versatile Fr-4 Glass Epoxy Laminate serves multiple industries:

Electronics Manufacturing:

- Printed circuit sheets (PCBs)

- Electronic lodgings and enclosures

- Insulation components

Industrial Applications:

- Mechanical basic parts

- Electrical separator systems

- High-temperature components

Specialized Uses:

- Aerospace components

- Automotive electronics

- Telecommunications equipment

OEM Service

We give comprehensive OEM arrangements custom fitted to your determinations. Our building group works with you to create custom details and measurements. You get materials outlined particularly for your application requirements.

Custom Services Include:

- Specialized thickness requirements

- Unique dimensional specifications

- Modified resin systems

- Custom color options

FAQ

Q: What makes this Fr-4 Glass Epoxy Laminate different from standard materials?

A: Our progressed 7628 electronic cloth combined with premium epoxy gum conveys predominant mechanical and electrical properties compared to standard laminates.

Q: Can you provide materials for high-volume production?

A: Yes, our 30,000-ton annual capacity supports large-scale manufacturing requirements with consistent quality.

Q: What flame retardant grades are available?

A: We offer both UL94V0 and UL94V1 flame retardant grades to meet your safety requirements.

Q: Do you offer technical support for material selection?

A: Our specialized group gives comprehensive bolster to offer assistance you select the ideal fabric details for your application.

Q: What are the standard delivery timeframes?

A: Delivery times vary based on order size and specifications. Contact us for specific timing requirements.

Contact Us

Ready to discuss your Fr-4 Glass Epoxy Laminate requirements? Our technical team stands ready to help you find the perfect solution for your application needs.

Email: info@jhd-material.com

Payment Terms: T/T

Shipping Options: Ocean, Land, Air transport available

Packaging: Standard protective packaging with pallet protection

Contact us nowadays to examine your particular necessities and get point by point specialized determinations. We see forward to supporting your following extend with our high-quality composite materials.

Send Inquiry