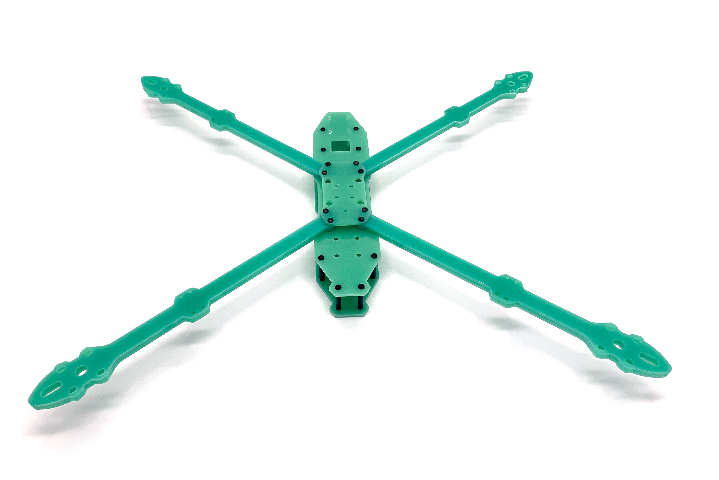

High Performance Epoxy Glass Laminate Sheet

Basic Information:

Brand:JingHong

Materials: 7628 electronic cloth + Epoxy Resin

Grade: UL94V1,UL94V0,NEMA

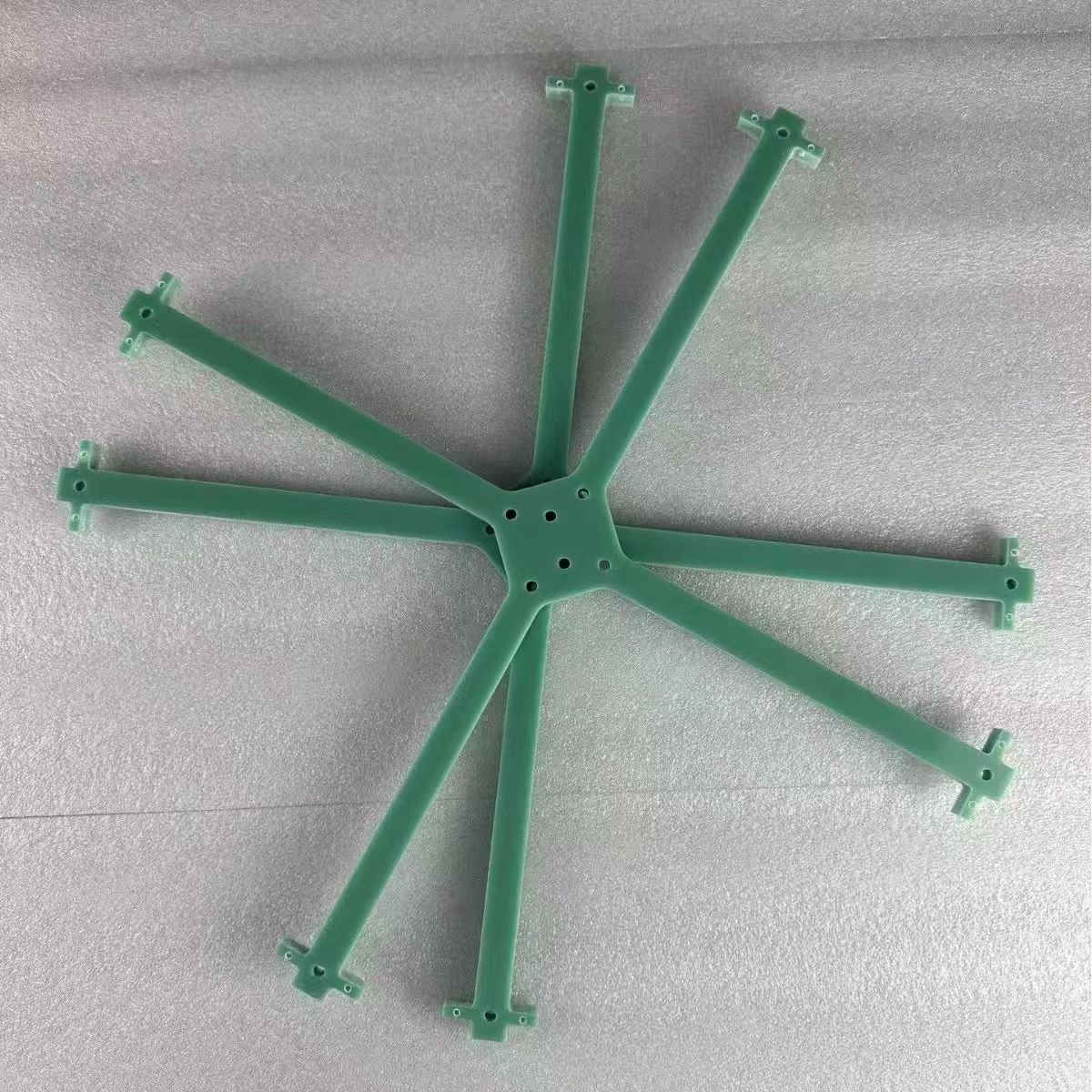

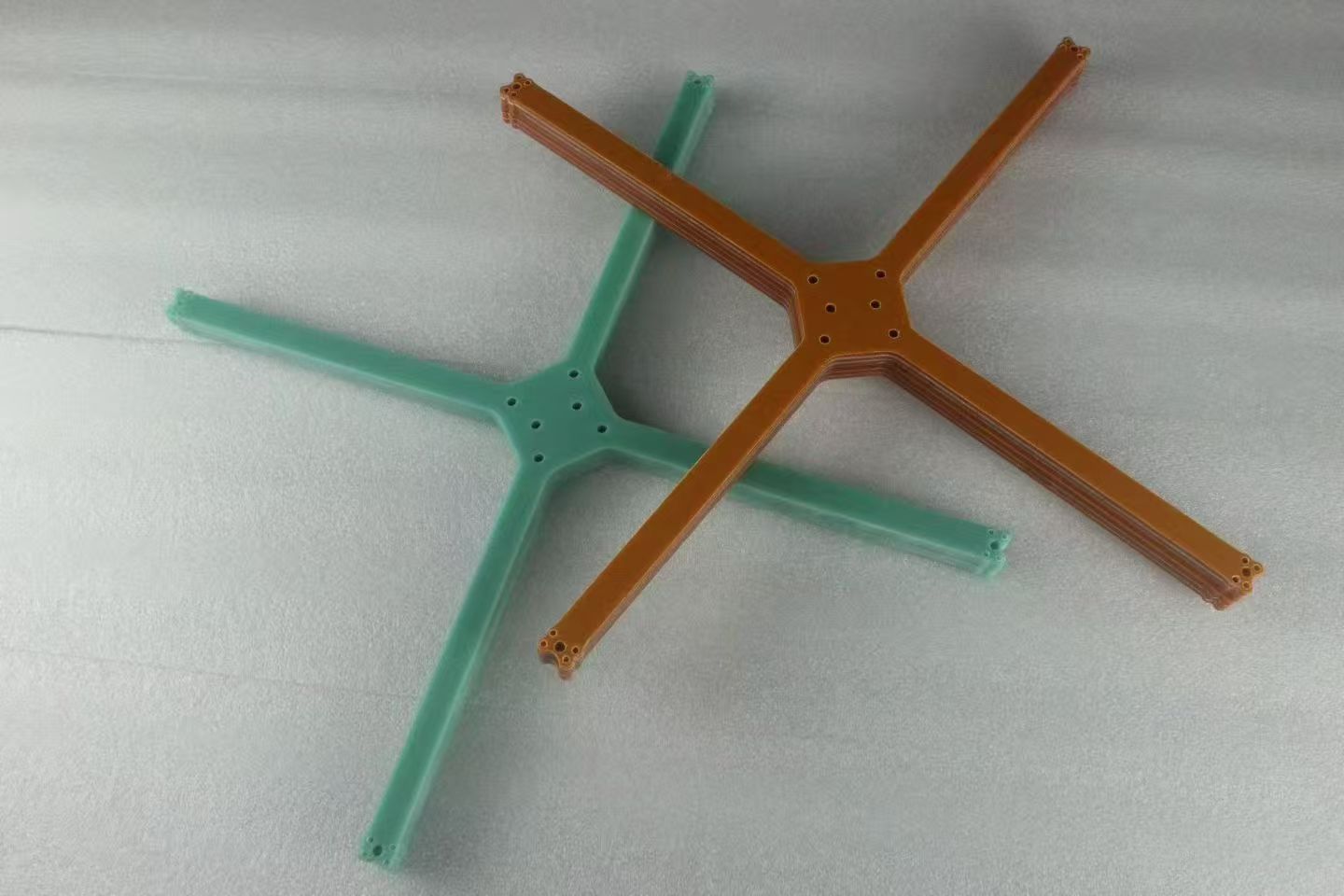

Nature Color: Light Green

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm,1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

High Performance Epoxy Glass Laminate Sheet - Professional Grade Material Solutions

When you require solid electrical cover and mechanical quality, our High Performance Epoxy Glass Laminate Sheet conveys uncommon comes about. Made with premium 7628 electronic cloth and progressed epoxy tar, this fabric offers predominant execution for requesting applications. Our JingHong brand sheets meet strict industry guidelines and give steady quality you can believe. Whether you're working on PCB fabricating or engine cover ventures, this cover sheet guarantees ideal performance.

Product Descriptions from the Supplier

Our epoxy glass cover sheets combine cutting-edge materials science with demonstrated fabricating strategies. Each sheet employments high-quality 7628 electronic cloth fortification fortified with extraordinarily defined epoxy gum. This makes a composite fabric that stands up to electrical current whereas keeping up great mechanical properties.

The light green color gives simple recognizable proof and proficient appearance. Our fabricating handle guarantees uniform thickness and reliable fabric properties all through each sheet.

Product Availability

We maintain substantial inventory levels to meet your project deadlines. With a production capacity of 30,000 tons annually, we can handle both small prototype orders and large-scale manufacturing requirements.

| Attribute | Details |

|---|---|

| Minimum Order Quantity | 500kg |

| Standard Lead Time | Contact us for current availability |

| Custom Orders | Available with advance planning |

Key Features

- Superior electrical separator properties for secure operation

- Excellent mechanical quality with transverse flexural quality ≥340 MPa

- Flame retardant grades counting UL94V1 and UL94V0 options

- Multiple thickness alternatives from 0.3mm to 100mm

- Flexible measuring with both standard and custom measurements available

- Lightweight however strong development for simple handling

- Chemical resistance against common mechanical solvents

- Temperature solidness for reliable performance

Standards

Our materials comply with internationally recognized standards:

- NEMA Review certification for electrical applications

- UL94V0 and UL94V1 fire retardancy ratings

- RoHS compliant for natural safety

- IPC measures for PCB applications

These certifications guarantee you get materials that meet or surpass industry necessities for security and performance.

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

Safety remains our best need all through the fabricating prepare. We execute comprehensive quality control measures:

- Raw fabric review some time recently generation begins

- In-process observing amid cover and curing

- Final testing of mechanical and electrical properties

- Batch following for total traceability

- Environmental testing to confirm execution beneath different conditions

Every High Performance Epoxy Glass Laminate Sheet undergoes rigorous testing to ensure it meets our strict quality standards before shipment.

Product Application

These flexible cover sheets serve various businesses and applications:

Electronics Industry:

- High-end PCB circuit boards

- Electronic equipment housings

- Transformer insulation components

Motor Manufacturing:

- Motor insulation systems

- Generator components

- Electrical panel assemblies

Industrial Applications:

- Structural components requiring electrical isolation

- Fixtures and jigs for electrical testing

- Protective barriers in electrical equipment

OEM Service

We get it that your ventures frequently require particular measurements or properties. Our experienced designing group works closely with you to create customized solutions.

Custom Services Include:

- Non-standard measurements and thicknesses

- Special cutting and machining services

- Modified gum details for particular requirements

- Private labeling options

- Technical interview and fabric determination guidance

Our adaptable fabricating capabilities permit us to suit special details whereas keeping up quality standards.

Certification

FAQ

Q: What thicknesses are immediately available?

A: We stock common thicknesses from 0.3mm to 25mm. Thicker sheets up to 100mm are available with longer lead times.

Q: Can you provide custom cutting services?

A: Yes, we offer precision cutting to your specifications. Contact us with your drawings for quotation.

Q: What payment terms do you accept?

A: We accept T/T (Telegraphic Transfer) with flexible terms based on order size and customer relationship.

Q: How do you ensure consistent quality?

A: Our quality control framework incorporates approaching fabric assessment, prepare observing, and last item testing some time recently shipment.

Q: What shipping options are available?

A: We ship by ocean freight for large orders, land transportation for regional delivery, and air freight for urgent requirements.

When you choose our High Performance Epoxy Glass Laminate Sheet, you're investing in proven performance and reliable supply chain support.

Contact Us

Ready to examine your particular prerequisites? Our specialized group is here to offer assistance you select the right fabric for your application.

Email: info@jhd-material.com

Contact us nowadays for specialized determinations, estimating data, or to ask tests. We see forward to supporting your another venture with high-quality cover arrangements.

Send Inquiry

You May Like

0

_1765955136885.jpg)

_1765955136760.jpg)

_1765955136492.jpg)