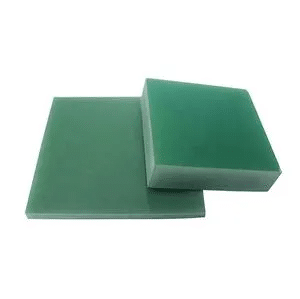

Epoxy Fiberglass Sheets

Basic Information:

Brand:JingHong

Materials: 7628 electronic cloth + Epoxy Resin

Grade: UL94V1,UL94V0,NEMA

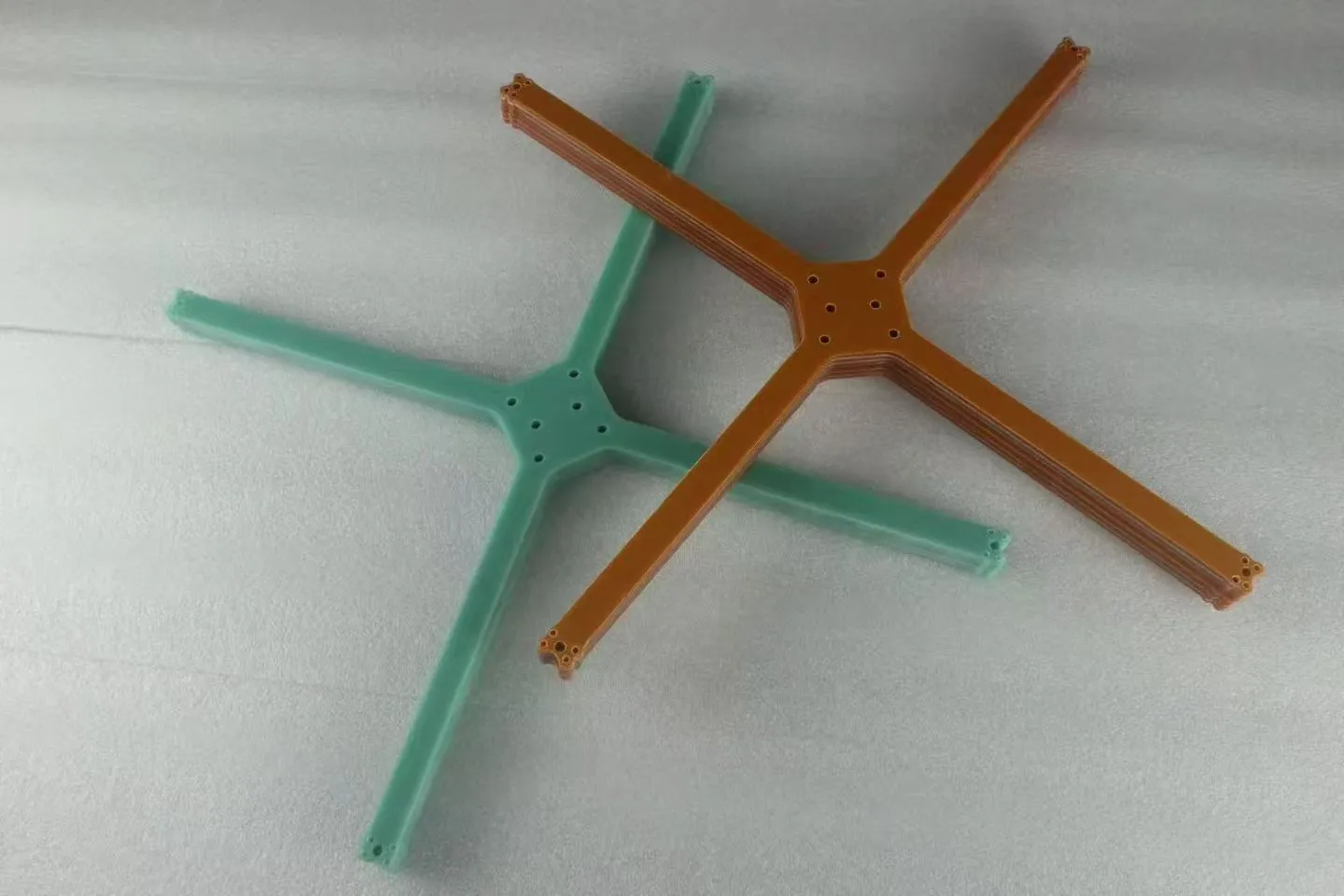

Nature Color: Light Green

Thickness: 0.3mm --- 100mm

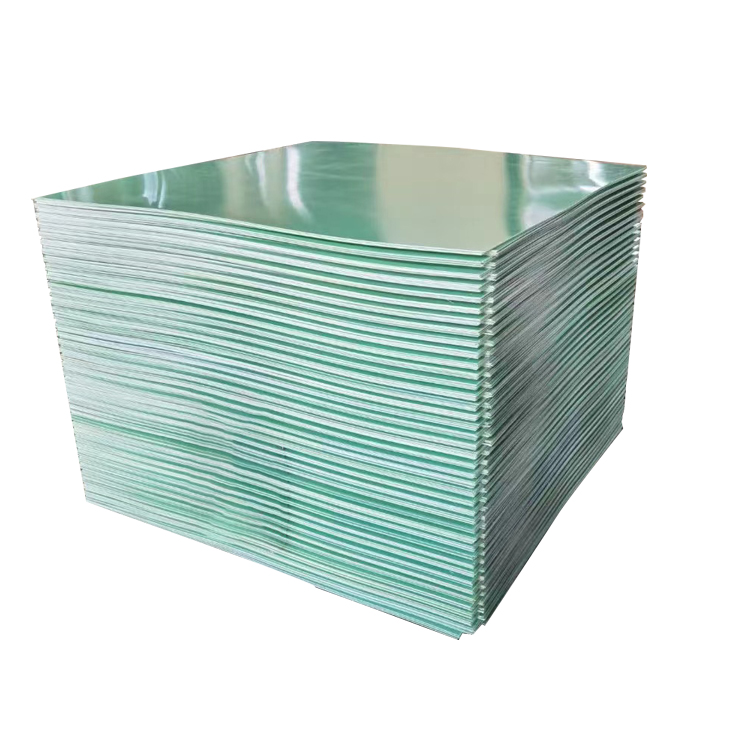

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm,1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

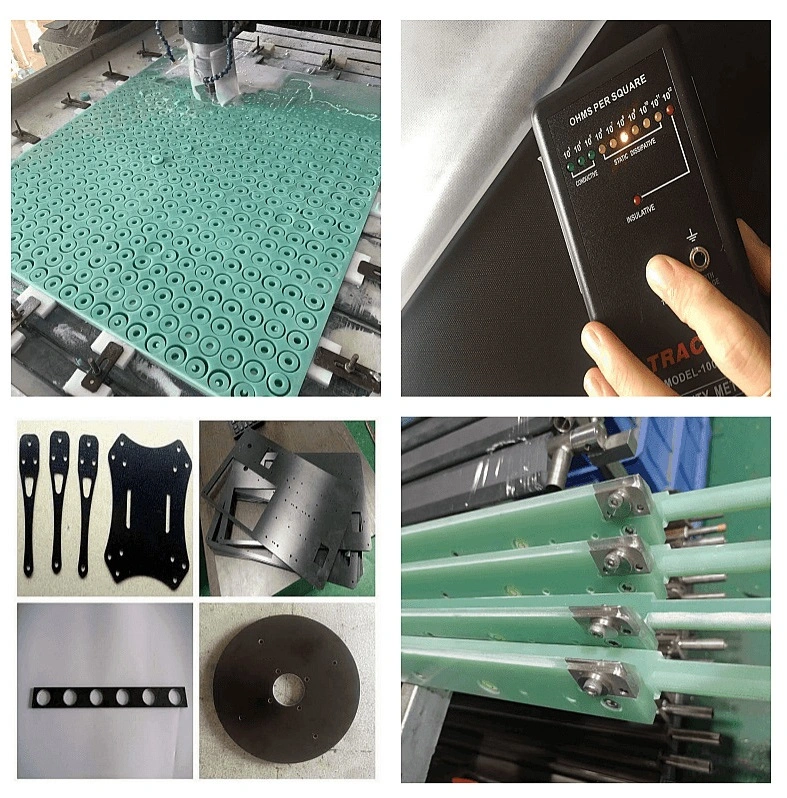

Professional Epoxy Fiberglass Sheets - High-Quality Electrical Insulation Solutions

Our Epoxy Fiberglass Sheets combine premium 7628 electronic cloth with high-grade epoxy gum to make predominant composite materials. These sheets give exceptional electrical separator properties, mechanical quality, and warm solidness for your mechanical applications. Whether you require standard sizes or custom measurements, we make quality arrangements that meet your particular requirements.

Product Description from Supplier

JingHong brand composite materials speak to a long time of fabricating mastery in the electrical cover industry. Our sheets highlight a carefully built combination of 7628 electronic cloth and epoxy gum, making a strong fabric that withstands requesting mechanical conditions.

Each sheet experiences thorough quality control forms to guarantee steady execution. The fabricating handle includes exact resin-to-fabric proportions that optimize both electrical and mechanical properties.

Product Availability

We keep up an yearly generation capacity of 30,000 tons, guaranteeing solid supply for your ventures. Stock accessibility shifts by thickness, with common details promptly accessible for prompt shipment.

| Specification | Details |

|---|---|

| Standard Thicknesses | 0.3mm to 100mm |

| Regular Sizes Available | 1020mm × 1220mm |

| 1220mm × 2440mm | |

| 1020mm × 2020mm | |

| Custom Sizes | 1030mm × 2030mm |

| 1030mm × 1030mm | |

| 1030mm × 2070mm | |

| Minimum Order Quantity | 500KG |

| Color | Light Green (Natural) |

Key Features

Superior Electrical Separator: Fabulous dielectric properties ensure your electrical components from voltage breakdown and current leakage.

High Mechanical Quality: Vigorous development withstands physical push, affect, and mechanical wear in requesting environments.

Thermal Soundness: Keeps up execution characteristics over wide temperature ranges without degradation.

Chemical Resistance: Stands up to oils, solvents, and other mechanical chemicals commonly found in electrical applications.

Dimensional Solidness: Negligible development or compression guarantees reliable fit and execution over time.

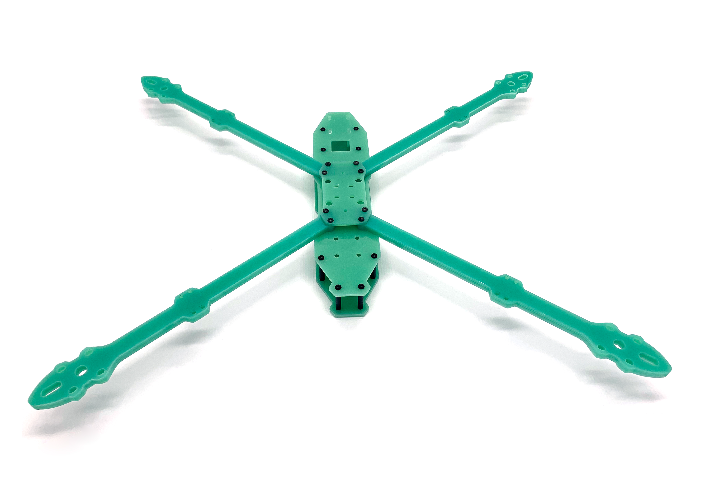

Easy Machining: Cuts, drills, and shapes effectively utilizing standard instruments for exact component fabrication.

Standards

Our fabricating forms comply with globally recognized electrical security standards:

- UL94V1 fire retardant rating

- UL94V0 upgraded fire retardant rating

- NEMA (National Electrical Producers Affiliation) specifications

These certifications guarantee your ventures meet security prerequisites and administrative compliance standards.

Technical Features: Product Safety Control

Quality Assurance Process:

- Incoming fabric assessment for all crude components

- In-process checking amid cover and curing

- Final item testing for electrical and mechanical properties

- Dimensional confirmation for all wrapped up sheets

Testing Protocols:

- Dielectric quality testing

- Flexural quality measurement

- Thermal avoidance temperature analysis

- Flame retardancy verification

Traceability: Total bunch following guarantees item consistency and empowers speedy reaction to any quality concerns.

Product Applications

Electrical Gear: Transformer separator, switchgear components, and engine space wedges advantage from great dielectric properties.

Electronics Fabricating: Circuit board substrates and electronic component lodgings require solid cover materials.

Industrial Apparatus: Bearing retainers, equip components, and auxiliary underpins utilize the material's mechanical strength.

Automotive Industry: Under-hood components and electrical framework insulin withstand cruel working conditions.

Marine Applications: Watercraft building and marine electrical frameworks require moisture-resistant separator solutions.

Aerospace: Insides boards and electrical component lodgings request lightweight, fire-resistant materials.

OEM Service

We get it that each application has one of a kind necessities. Our designing group works closely with you to create custom arrangements that coordinate your correct specifications.

Custom Services Include:

- Precise thickness control for particular applications

- Custom measuring and cutting to decrease waste

- Special tar definitions for upgraded properties

- Color coordinating for tasteful requirements

- Technical meeting for fabric selection

Our experienced engineers provide application guidance to help you select the optimal Epoxy Fiberglass Sheets configuration for your project needs.

FAQ

Q: What shipping methods do you offer?

A: We provide sea freight, air freight, and express delivery options to meet your timeline requirements.

Q: Do you maintain inventory for immediate shipping?

A: Yes, we stock standard thicknesses for quick delivery. Custom specifications may require additional production time.

Q: What is your resin-to-fabric ratio?

A: Our proprietary formula optimizes performance characteristics. Each manufacturer develops specific ratios for their applications.

Q: Can you provide technical support for material selection?

A: Absolutely! Our technical team helps you choose the right specifications for your specific application requirements.

Q: What payment terms do you accept?

A: We accept T/T (telegraphic transfer) payment terms for international orders.

Q: How do you ensure product quality?

A: Every batch undergoes comprehensive testing including electrical, mechanical, and dimensional verification before shipment.

Contact Us

Ready to discuss your Epoxy Fiberglass Sheets requirements? Our technical sales team provides expert guidance for material selection and application support.

Email: info@jhd-material.com

Contact us nowadays for estimating, specialized determinations, or custom arrangement advancement. We're here to offer assistance you discover the idealize cover fabric for your extend needs.

Send Inquiry

You May Like

0