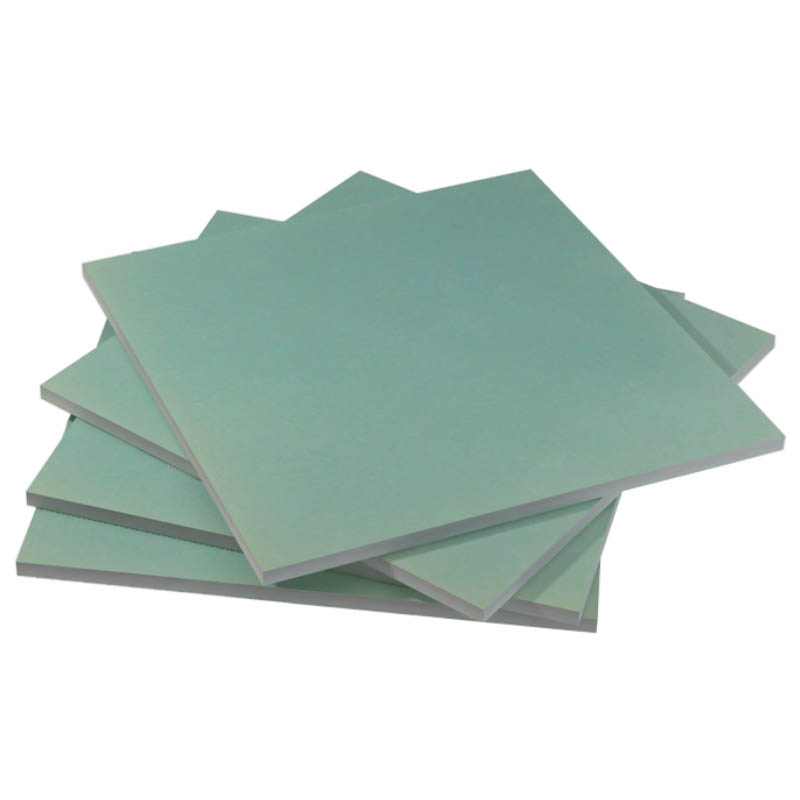

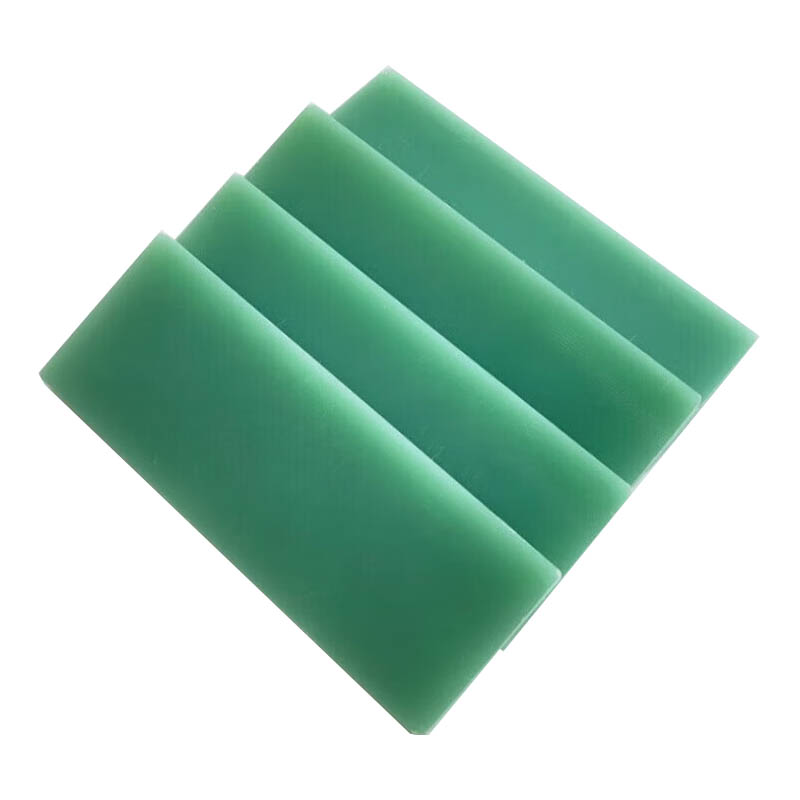

Epoxy Glass Laminate Sheet

Basic Information:

Brand:JingHong

Materials: 7628 electronic cloth + Epoxy Resin

Grade: UL94V1,UL94V0,NEMA

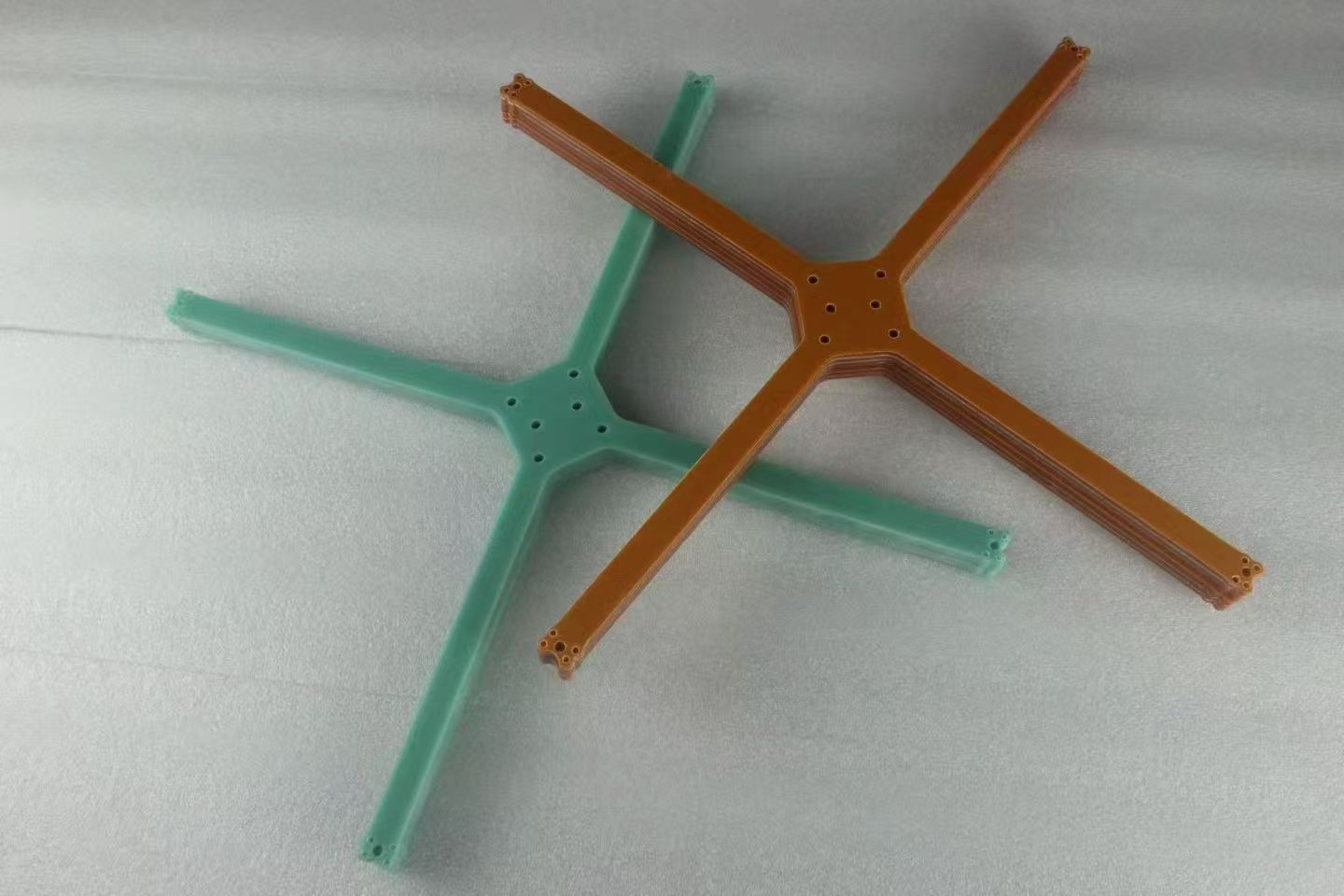

Nature Color: Light Green

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm,1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

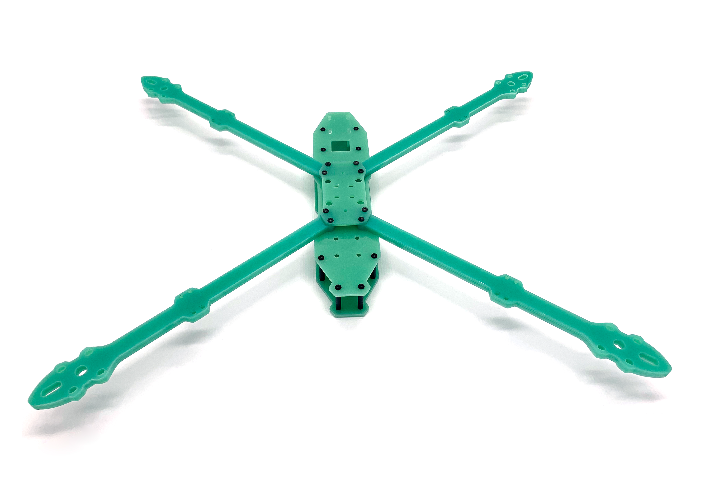

High-Performance Epoxy Glass Laminate Sheet for Electronics & Insulation Applications

When you require dependable electrical cover materials for your ventures, our Epoxy Glass Laminate Sheet conveys uncommon execution and solidness. Made from premium 7628 electronic cloth combined with high-grade epoxy gum, these sheets give extraordinary mechanical quality and electrical properties. Whether you're working on PCB manufacture, electrical gear fabricating, or separator applications, our product offers the quality and consistency your ventures request. With over 30,000 tons yearly generation capacity, we guarantee solid supply for your trade needs.

Product Description from JingHong

Our premium cover sheets speak to the culminate combination of progressed materials innovation and fabricating greatness. Each sheet experiences thorough quality control forms to meet universal guidelines. The light green characteristic color gives simple recognizable proof whereas keeping up proficient appearance in your applications.

Product Availability

| Specification | Details |

|---|---|

| Brand | JingHong |

| Materials | 7628 Electronic Cloth + Epoxy Resin |

| Standard Colors | Light Green (natural) |

| Thickness Range | 0.3mm to 100mm |

| Regular Sizes | 1020mm × 1220mm |

| 1220mm × 2440mm | |

| 1020mm × 2020mm | |

| Custom Sizes | 1030mm × 2030mm |

| 1030mm × 1030mm | |

| 1030mm × 2070mm | |

| Annual Production Capacity | 30,000 tons |

| Minimum Order Quantity | 500KG |

Key Features

Our cover sheets offer prevalent execution characteristics that make them perfect for requesting applications:

- Excellent Electrical Cover: Exceptional dielectric properties for solid electrical isolation

- High Mechanical Quality: Prevalent pliable and flexural quality for basic applications

- Temperature Resistance: Steady execution over wide temperature ranges

- Chemical Resistance: Fabulous resistance to oils, solvents, and mechanical chemicals

- Dimensional Steadiness: Negligible distorting and reliable dimensions

- Easy Machining: Clean cutting and penetrating without delamination

Standards & Grades

We fabricate sheets assembly different universal standards:

- UL94V1 Review: Improved fire retardancy for safety-critical applications

- UL94V0 Review: Predominant fire resistance with self-extinguishing properties

- NEMA Benchmarks: Full compliance with North American electrical standards

Technical Data for FR4

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-0 |

GB/T 2408-2008 |

REMARK:1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

Quality Assurance Parameters

- Shear Quality (Parallel Layers): ≥300 MPa - guaranteeing vigorous auxiliary integrity

- Impact Quality (Parallel Heading): ≥37 KJ/m² - great resistance to mechanical shock

- Water Retention Rate: ≤0.5% - negligible dampness take-up for steady performance

Our comprehensive testing conventions confirm each clump meets these exacting necessities. We conduct normal reviews all through the fabricating handle to keep up reliable quality.

Product Applications

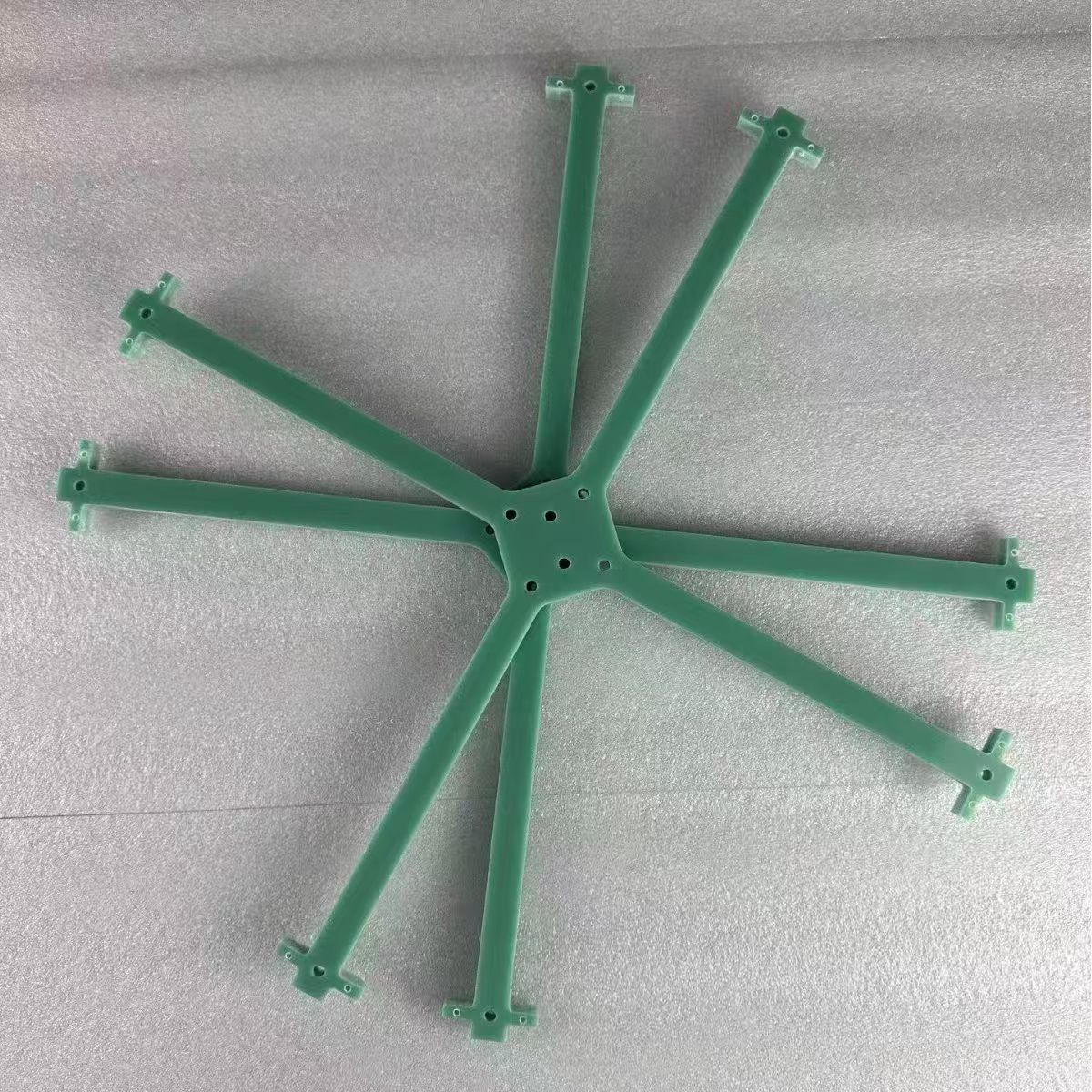

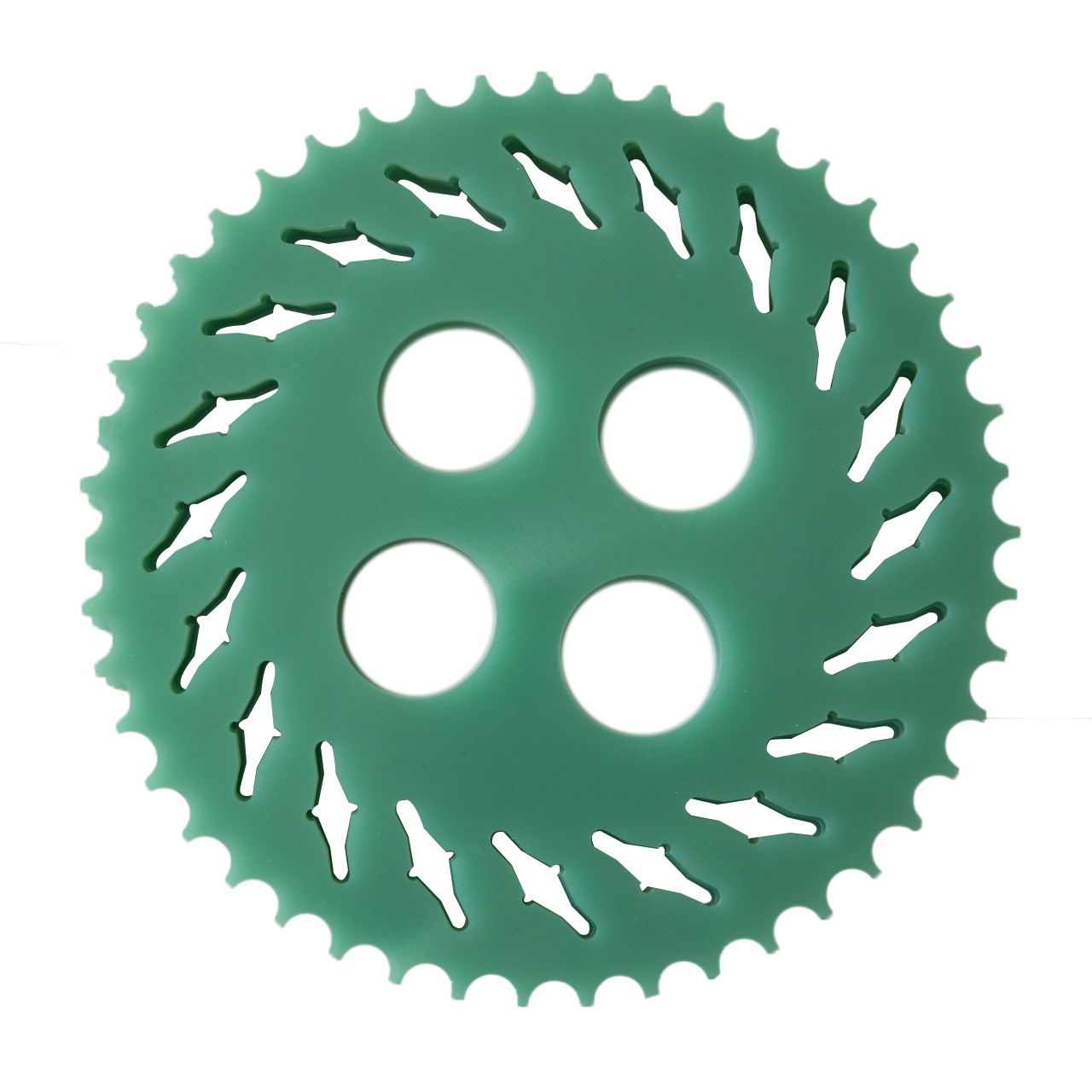

The versatility of our Epoxy Glass Laminate Sheet makes it suitable for numerous industries:

Electronics Industry

- Printed Circuit Board substrates

- Electrical panel insulation

- Transformer components

- Switchgear applications

Industrial Applications

- Mechanical insulation parts

- Structural components

- Jigs and fixtures

- Chemical processing equipment

Aerospace & Defense

- Insulation components

- Structural panels

- Electronic housing

OEM Service

We get it that each extend has one of a kind prerequisites. Our experienced designing group works closely with you to create customized arrangements. Whether you require particular measurements, altered properties, or extraordinary bundling, we adjust our fabricating forms to meet your correct specifications.

Custom Services Include:

- Precision cutting to your dimensions

- Special thickness requirements

- Modified surface treatments

- Custom packaging solutions

- Technical support and consultation

Certifications

Frequently Asked Questions

Q: What's the typical lead time for standard sizes?

A: Standard sizes are usually available within 2-3 weeks, depending on quantity and current inventory levels.

Q: Can you provide material test certificates?

A: Yes, we provide comprehensive test reports with every shipment, including mechanical, electrical, and thermal properties.

Q: What packaging options are available?

A: We offer standard pallet packaging with protective covering. Custom packaging solutions are available for special requirements.

Q: Do you offer technical support for material selection?

A: Absolutely! Our technical team provides expert guidance to help you select the optimal grade and thickness for your specific application.

Q: What payment terms do you accept?

A: We accept T/T (wire transfer) payments. Other payment arrangements can be discussed for established customers.

Contact Us

Ready to enhance your projects with high-quality Epoxy Glass Laminate Sheet? Our technical sales team is here to help you find the perfect solution for your applications.

Email: info@jhd-material.com

Get in touch nowadays for competitive estimating, specialized details, or custom prerequisites. We're committed to giving you with solid materials and extraordinary benefit that surpasses your desires.

Send Inquiry

You May Like

0