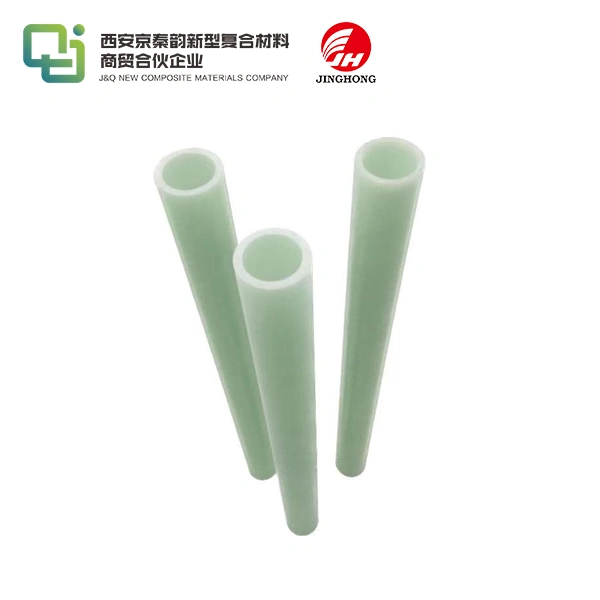

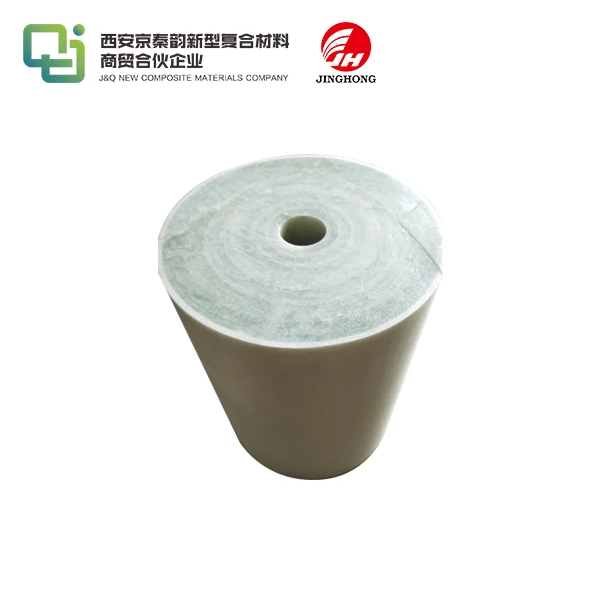

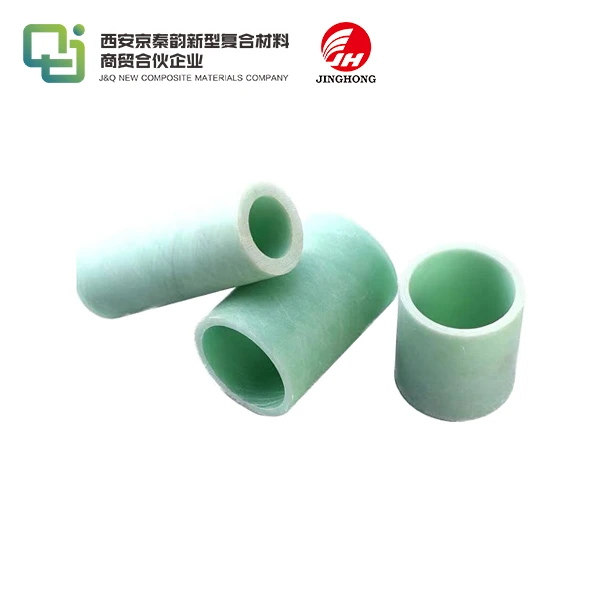

3520 Phenolic Paper Pipe

Basic information:

Brand: Jinghong

Materials: Phenolic Resin

Nature Color: Brownish

Wall thickness: At least 2mm

Custom Size: Inner diameter:φ8mm~φ550mm

Outer diameter φ6mm~φ1000mm

Packaging: Regular packing

Productivity: 1000 tons per year

Transportation: Ocean, Land, Air

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

3520 Phenolic Paper Pipe: High-Performance Insulation for Industrial Applications

J&Q New Composite Materials Company is a leading manufacturer and supplier of 3520 phenolic paper pipes. Our progressed generation offices and decades of involvement guarantee top-quality separator arrangements for different businesses. J&Q's items offer prevalent warm resistance, great electrical cover, and exceptional strength, making them the perfect choice for requesting applications.

Product Description

Our items are built to meet the most elevated benchmarks of execution and unwavering quality. These tubes combine the remarkable quality of phenolic tar with the versatility of paper to outperform desires in both electrical and mechanical applications. Whether you require security for motors, transformers, or high-voltage equipment, our items offer uncommon comes about and reliable quality.

Technical Specifications

- Material: Phenolic resin impregnated paper

- Dielectric strength: Up to 20 kV/mm

- Temperature resistance: -60°C to +155°C

- Tensile strength: ≥100 MPa

- Water absorption: ≤2%

- Specific gravity: 1.3-1.4 g/cm³

- Standard lengths: 1000mm, 1200mm (custom lengths available)

- Inner diameter range: 6mm to 600mm

- Wall thickness range: 0.5mm to 30mm

Applications

3520 phenolic paper pipes find extensive use in various industries:

- Electrical:

- Transformer insulation

- Motor winding insulation

- Switchgear components

- Industrial:

- High-temperature mechanical bushings

- Thermal insulation sleeves

- Abrasion-resistant rollers

- Automotive:

- Electrical system insulation

- Structural components in high-heat areas

- Aerospace:

- Lightweight insulating structures

- Electrical conduits in aircraft systems

How to Use?

- Measure and cut: Use a fine-toothed saw or specialized cutting tool to achieve clean, precise cuts.

- Deburr edges: Smooth any rough edges to ensure proper fit and prevent damage to wires or components.

- Install: Slide the pipe over the component or use it as a structural element in your assembly.

- Secure: Use appropriate adhesives or mechanical fasteners compatible with phenolic materials if needed.

- Test: Verify proper insulation and mechanical properties after installation.

Why Choose Us?

- Quality Assurance: Our state-of-the-art facilities and rigorous quality control ensure consistently high-quality products.

- Customization: We offer tailored solutions to meet your specific requirements, including custom sizes, colors, and properties.

- Technical Expertise: Our team of experienced engineers provides comprehensive support throughout your project.

- Competitive Pricing: As a large-scale manufacturer, we offer attractive bulk pricing without compromising on quality.

- Reliable Supply: With two advanced production facilities, we guarantee stable supply and on-time delivery.

- Worldwide Reach: Our items are traded around the world, with a solid nearness in key markets like Russia, Southeast Asia, the Joined together States, and Europe.

- Integrated Logistics: Our in-house logistics company ensures smooth, efficient delivery of your orders.

Qualification Certification

J&Q New Composite Materials Company maintains the highest standards of quality and compliance:

- ISO 9001 Quality Management System Certification

- UL Certification for electrical insulation materials

- RoHS Compliance for environmental safety

- CHENG SHI SHOU XIN DAN WEI (City Trustworthy Unit) recognition

- Consumer Satisfaction Trust Units award

Transaction Feedback

Our commitment to customer satisfaction is reflected in the positive feedback we receive:

"J&Q's products have significantly improved the reliability of our transformer production. Their consistent quality and on-time delivery have made them our go-to supplier." - James H., Procurement Manager, ElectroPower Inc.

"The technical support from J&Q's team is outstanding. They helped us optimize our insulation design, leading to better performance and cost savings." - Sarah L., Chief Engineer, InnovaTech Solutions

Exhibition

FAQ

Q: What are the minimum order quantities for products?

A: We offer flexible order quantities to meet your needs. Contact us for details on bulk pricing and minimum order requirements.

Q: Can you produce custom sizes of the products?

A: Yes, we specialize in custom manufacturing. Our advanced equipment allows us to produce pipes in a wide range of diameters and lengths.

Q: What is the lead time for the product orders?

A: Lead times vary based on order volume and specifications. Typical lead times range from 2-4 weeks for standard sizes, with custom orders potentially requiring additional time.

Q: Are your products compliant with international standards?

A: Yes, our products meet or exceed various international standards for electrical insulation and mechanical properties. We can provide relevant certifications upon request.

Q: How do the products compare to other insulation materials?

A: The products offer an excellent balance of electrical insulation, heat resistance, and mechanical strength. They often outperform alternatives in high-temperature or high-voltage applications.

Contact Us

Ready to upgrade your insulation solutions with our high-quality products? Contact J&Q New Composite Materials Company today for expert advice, custom quotes, and unparalleled support.

Email: info@jhd-material.com

Experience the difference with J&Q's 3520 phenolic paper pipes – where innovation meets reliability in industrial insulation.

Send Inquiry

_1755583592640.webp)

_1755583592095.webp)

_1755583592174.webp)

_1755583592177.webp)

_1747991245292.webp)