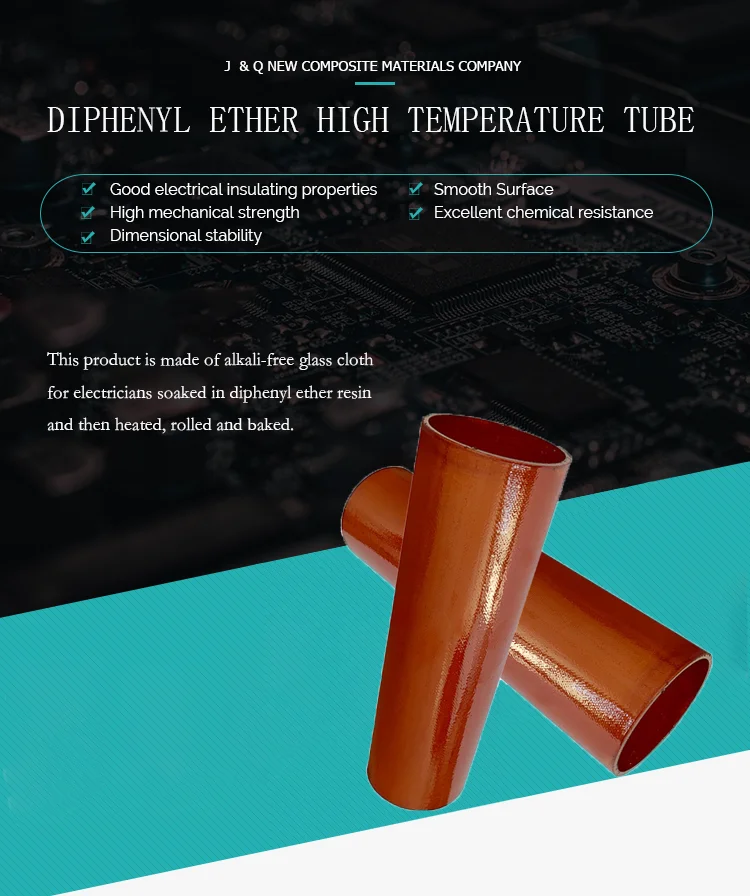

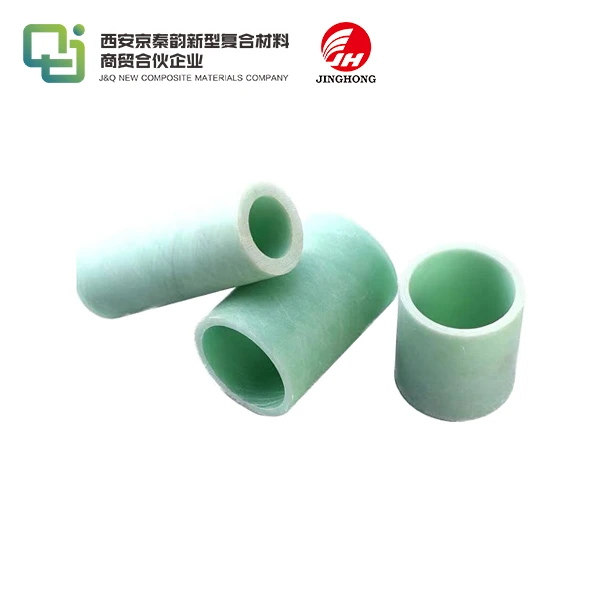

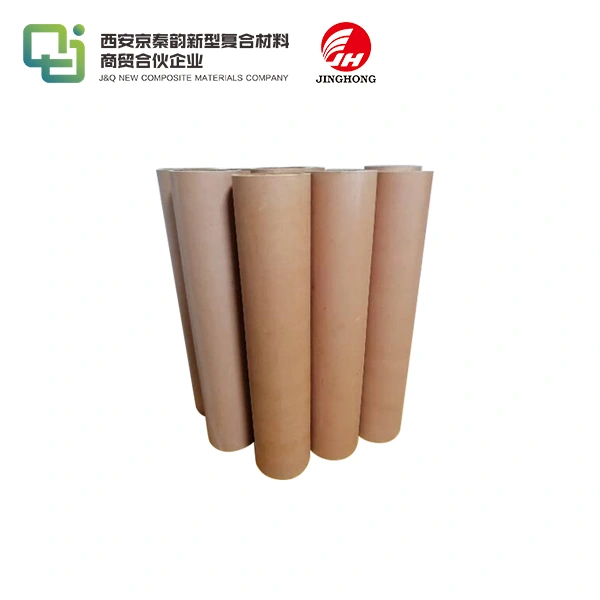

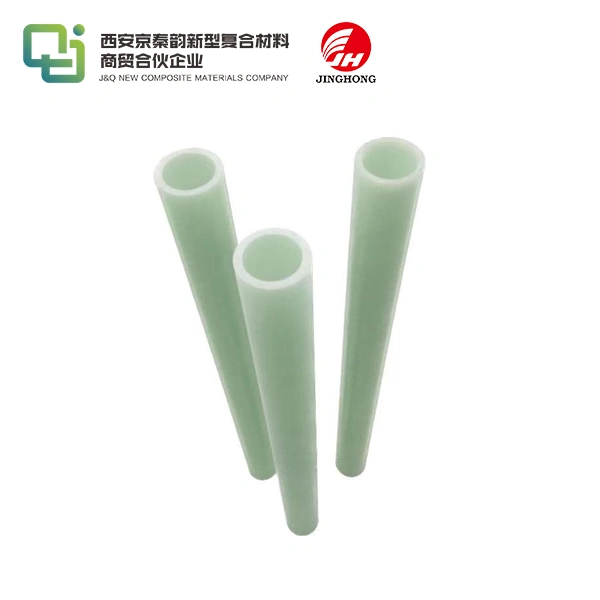

Diphenyl Ether Fiberglass Cloth Tube

Basic information:

Brand: Jinghong

Materials: FiberGlass

Nature Color: red

Wall thickness: At least 0.5mm

Custom Size: Inner diameter φ8mm~φ500mm

Outer diameter φ10mm~φ2000mm

The longest tube length is 2m

Packaging: Regular packing

Productivity: 100 tons per year

Transportation: Ocean, Land, Air

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Diphenyl Ether Fiberglass Cloth Tubes: High-Performance Insulation for Demanding Applications

Welcome to J&Q New Composite Materials Company, your trusted manufacturer and supplier of premium diphenyl ether fiberglass cloth tubes. With over 20 a long time of encounter in separator materials, we pride ourselves on conveying top-quality items that meet the most exacting industry guidelines. Our items offer predominant warm resistance, great electrical cover, and extraordinary strength for a wide run of applications.

Product Description

Our products are engineered to provide outstanding performance in demanding environments. These high-grade insulation components combine the strength of fiberglass with the superior properties of diphenyl ether resin, resulting in a versatile material suited for various industrial applications.

Key Features

- Exceptional thermal resistance (up to 180°C continuous operation)

- Superior electrical insulation properties

- Excellent chemical resistance

- High mechanical strength and dimensional stability

- Flame retardant (UL 94 V-0 rated)

- Low moisture absorption

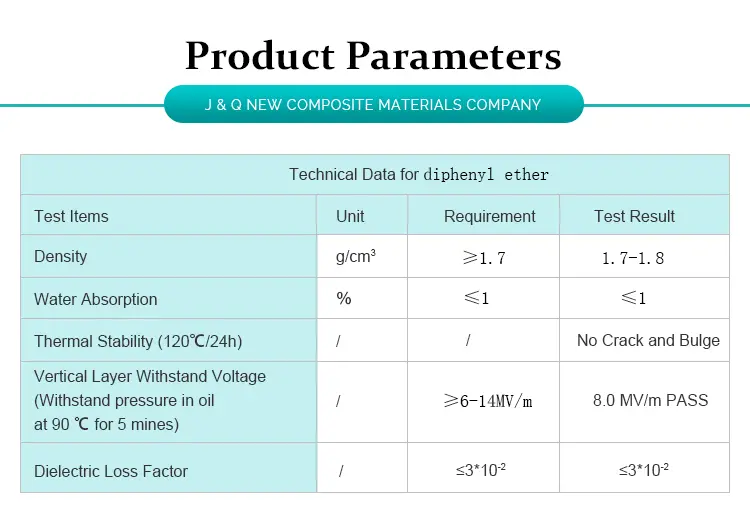

Technical Specifications

- Material: Diphenyl ether resin-impregnated fiberglass cloth

- Temperature Range: -40°C to +180°C (continuous operation)

- Dielectric Strength: ≥ 20 kV/mm

- Tensile Strength: ≥ 250 MPa

- Flexural Strength: ≥ 300 MPa

- Water Absorption: ≤ 0.1%

- Standard Wall Thickness: 0.5mm to 3mm (custom thicknesses available)

- Standard Diameters: 10mm to 100mm (custom sizes upon request)

- Standard Lengths: Up to 1000mm (longer lengths available)

Applications

The items discover broad utilize over different industries:

- Electrical & Electronics:

- Motor and transformer insulation

- High-voltage switchgear components

- Electrical bushing sleeves

- Aerospace & Defense:

- Aircraft wiring protection

- Thermal barriers in engine compartments

- Structural components requiring high heat resistance

- Automotive (especially EVs):

- Battery insulation systems

- Electric motor winding insulation

- Thermal management in power electronics

- Industrial Equipment:

- Insulation for industrial ovens and furnaces

- Chemical processing equipment lining

- Bearing isolation in high-temperature environments

- Renewable Energy:

- Solar inverter insulation

- Wind turbine electrical systems

- Geothermal power plant components

How to Use?

- Sizing: Select the appropriate diameter and wall thickness based on your application requirements.

- Cutting: Use a sharp cutting tool or fine-toothed saw to cut the tube to the desired length. Always wear appropriate personal protective equipment (PPE) when handling or cutting the material.

- Installation: Slide the tube over the component requiring insulation. For a tighter fit, the tube can be slightly expanded using heat (do not exceed the maximum temperature rating).

- Securing: If necessary, use heat-resistant adhesive tapes or clamps to secure the tube in place.

- Customization: For special requirements, such as adding slots or holes, please consult our technical team for guidance on proper modification techniques.

Why Choose Us?

- Quality Assurance: Our state-of-the-art fabricating offices and thorough quality control forms guarantee reliable, high-quality items that meet or surpass industry guidelines.

- Customization Capabilities: We offer tailored solutions to meet your specific needs, including custom sizes, thicknesses, and properties.

- Technical Expertise: Our team of experienced engineers provides comprehensive support from material selection to application optimization.

- Global Reach: With a solid nearness in worldwide markets, we offer dependable supply chain arrangements to clients around the world.

- Sustainability Focus: We are committed to developing eco-friendly materials and implementing sustainable manufacturing practices.

Qualification Certification

Our commitment to quality is backed by internationally recognized certifications:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- RoHS and REACH compliant

- UL 94 V-0 flame retardancy certification

Transaction Feedback

Don't just take our word for it. Here's what our customers say:

"J&Q's products have significantly improved the reliability of our high-voltage equipment. Their technical support team was instrumental in helping us optimize our insulation design." - Chief Engineer, Major Electrical Equipment Manufacturer

"We've been using J&Q products for over five years in our aerospace applications. The consistent quality and performance of their fiberglass tubes are unmatched." - Procurement Manager, Leading Aerospace Company

Exhibition

FAQ

Q: What is the minimum order quantity for the products?

A: Our standard MOQ is 100 meters. However, we can accommodate smaller quantities for sample or trial orders.

Q: Can you provide custom sizes or properties?

A: Yes, we offer customization services to meet specific requirements. Please contact our sales team with your detailed specifications.

Q: What is the lead time for standard products?

A: Typical lead time for standard sizes is 2-3 weeks. Custom orders may require additional time.

Q: Are your items compliant with universal measures?

A: Yes, our items comply with different worldwide benchmarks, counting UL, IEC, and ASTM details.

Q: Do you offer technical support for material selection and application?

A: Absolutely. Our experienced technical team is available to assist you in choosing the right product and optimizing its use in your application.

Contact Us

Ready to elevate your insulation performance with our diphenyl ether fiberglass cloth tubes? Contact J&Q New Composite Materials Company today for expert advice, custom solutions, or to request a quote.

Email: info@jhd-material.com

Let's work together to find the perfect insulation solution for your challenging applications!

Send Inquiry

_1747991245292.webp)

_1755583592640.webp)