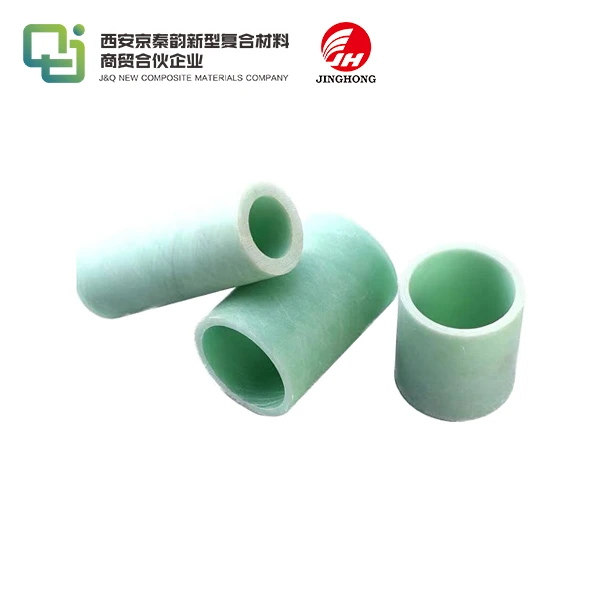

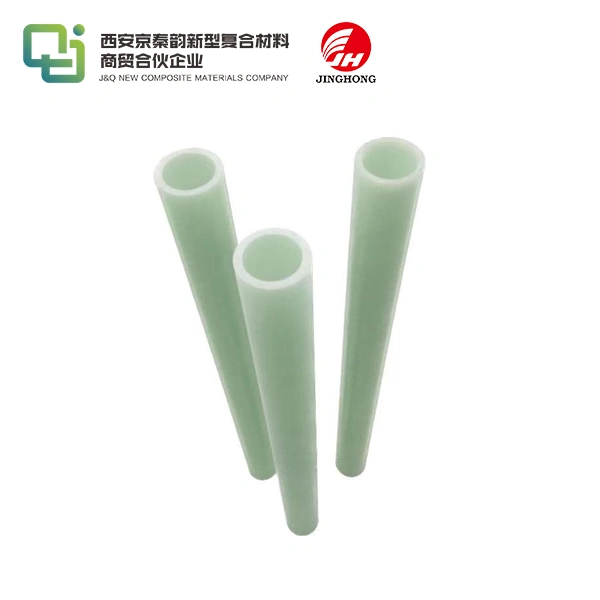

Black Phenolic Tube

Basic Information:

Brand: JingHong

Materials: Cotton Fabric + Phenolic Resin

Nature Color: Brown,Black

Wall thickness: At least 2mm

Custom Size: Inner diameter φ5mm~φ1500mm

Outer diameter φ6mm~φ2000mm

The longest tube length is 2m

Packaging: Regular packing

Productivity: 100 tons per year

Transportation: Ocean, Land, Air

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Black Phenolic Tube - Premium Composite Material Solution

Our Black Phenolic Tube offers remarkable execution and flexibility for different designing ventures. Made from high-quality cotton texture fortified with phenolic tar, this product delivers exceptional mechanical quality and chemical resistance. At J&Q Unused Composite Fabric Gather Co., Ltd, we specialize in fabricating premium composite materials that meet your correct details and execution requirements.

Description

Our phenolic tubes combine cotton texture fortification with progressed phenolic gum innovation. This special combination makes a composite fabric with amazing dimensional steadiness and predominant execution characteristics. The fabricating prepare guarantees reliable quality and dependable execution over all applications.

The tubes include a smooth wrap up and exact measurements. Each item experiences thorough quality testing to ensure execution measures. Our fabricating ability guarantees you get items that meet industry requirements.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Available Colors | Brown, Black |

| Custom Size Range | Inner Diameter: φ5mm to φ1500mm Outer Diameter: φ6mm to φ2000mm (minimum 8mm) Maximum Length: 2 meters Wall Thickness: Minimum 2mm |

| Production Capacity | 100 tons annually |

| Packaging | Standard industrial packaging |

| Shipping Options | Ocean, Land, and Air transportation |

Key Features

- High Temperature Resistance: Withstands temperatures up to 120℃

- Excellent Mechanical Quality: Cotton texture support gives predominant durability

- Chemical Resistance: Phenolic tar offers fabulous chemical stability

- Dimensional Exactness: Exact fabricating guarantees steady dimensions

- Customizable Details: Adaptable measuring alternatives for different applications

- Smooth Surface Wrap up: Proficient appearance and functionality

- Long Benefit Life: Tough development for expanded use

Standards

Our fabricating forms take after strict industry benchmarks. Quality control measures guarantee reliable item execution. Each clump experiences comprehensive testing some time recently shipment.

We keep up compliance with pertinent composite fabric benchmarks. Our quality administration framework guarantees solid item conveyance. Documentation is accessible for all items upon request.

Technical Features: Product Safety Control

Our security control framework incorporates different quality checkpoints all through generation. Crude fabric review guarantees as it were premium cotton texture and phenolic gum enter our fabricating process.

Temperature checking amid curing guarantees ideal tar cross-linking. Dimensional confirmation affirms exactness to your details. Surface quality assessment ensures smooth finishes.

Final item testing incorporates weight testing where pertinent. Quality documentation goes with each shipment. Our experienced group manages each generation step to keep up steady quality standards.

Product Application

These composite tubes exceed expectations in different mechanical applications:

Electrical Industry: Protection sleeves and defensive lodgings advantage from amazing dielectric properties.

Mechanical Designing: Bearing bushings and wear-resistant components utilize the material's durability.

Chemical Preparing: Hardware components requiring chemical resistance perform dependably in cruel environments.

Automotive Applications: Under-hood components advantage from temperature resistance and mechanical strength.

Aerospace Industry: Lightweight however solid components meet requesting execution requirements.

Marine Applications: Corrosion-resistant properties make these perfect for marine environments.

The flexibility of our Black Phenolic Tube makes it appropriate for custom applications requiring particular execution characteristics.

OEM Service

We give comprehensive OEM administrations custom fitted to your particular necessities. Our designing group works closely with you to create custom solutions.

Custom measuring guarantees culminate fit for your applications. We can adjust divider thickness, breadth, and length agreeing to your details. Uncommon surface medicines are accessible when required.

Prototype advancement makes a difference approve plans some time recently full generation. Our adaptable fabricating capabilities oblige both little bunches and expansive volume orders. Specialized back proceeds all through your venture lifecycle.

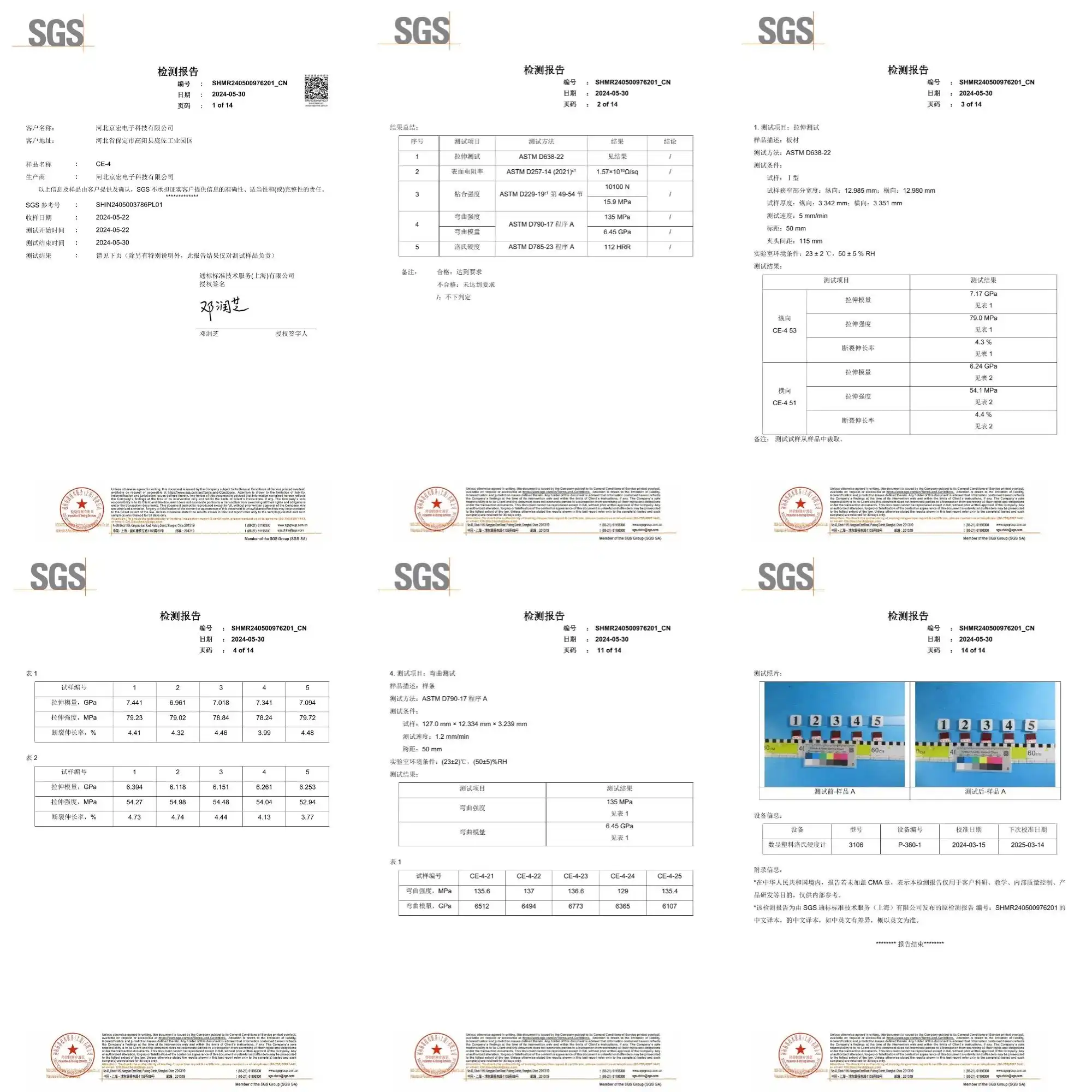

Certification

FAQ

Q: What is the minimum wall thickness available?

A: The minimum wall thickness is 2mm to ensure structural integrity and performance.

Q: Can you manufacture tubes smaller than 8mm outer diameter?

A: Our minimum outer diameter starts at 8mm due to manufacturing limitations.

Q: What temperature range can these tubes handle?

A: Our phenolic tubes withstand continuous operation at temperatures up to 120℃.

Q: Do you offer custom lengths beyond 2 meters?

A: Currently, our maximum tube length is 2 meters. Contact us to discuss special requirements.

Q: What lead time should I expect for custom orders?

A: Lead times vary based on specifications and quantity. Contact our team for specific project timelines.

Contact Us

Ready to discuss your Black Phenolic Tube requirements? Our technical team is here to help you select the right specifications for your application.

Contact us today for:

- Custom quotations

- Technical specifications

- Application guidance

- Sample requests

Email: info@jhd-material.com

Let us offer assistance you discover the culminate composite fabric arrangement for your another venture. Our skill guarantees you get items that meet your correct execution necessities.

Send Inquiry

_1747991245292.webp)

_1753952475136.jpg)